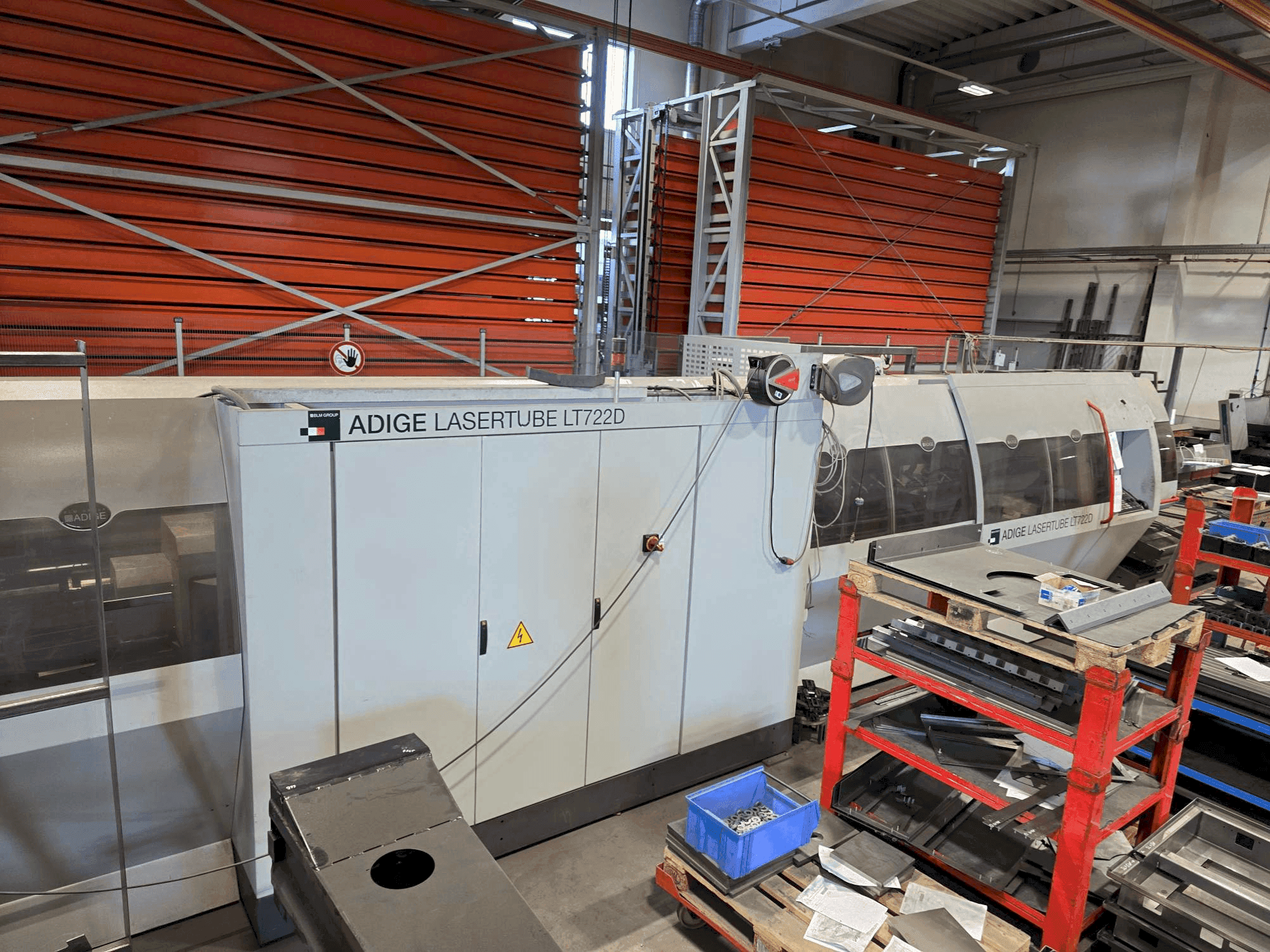

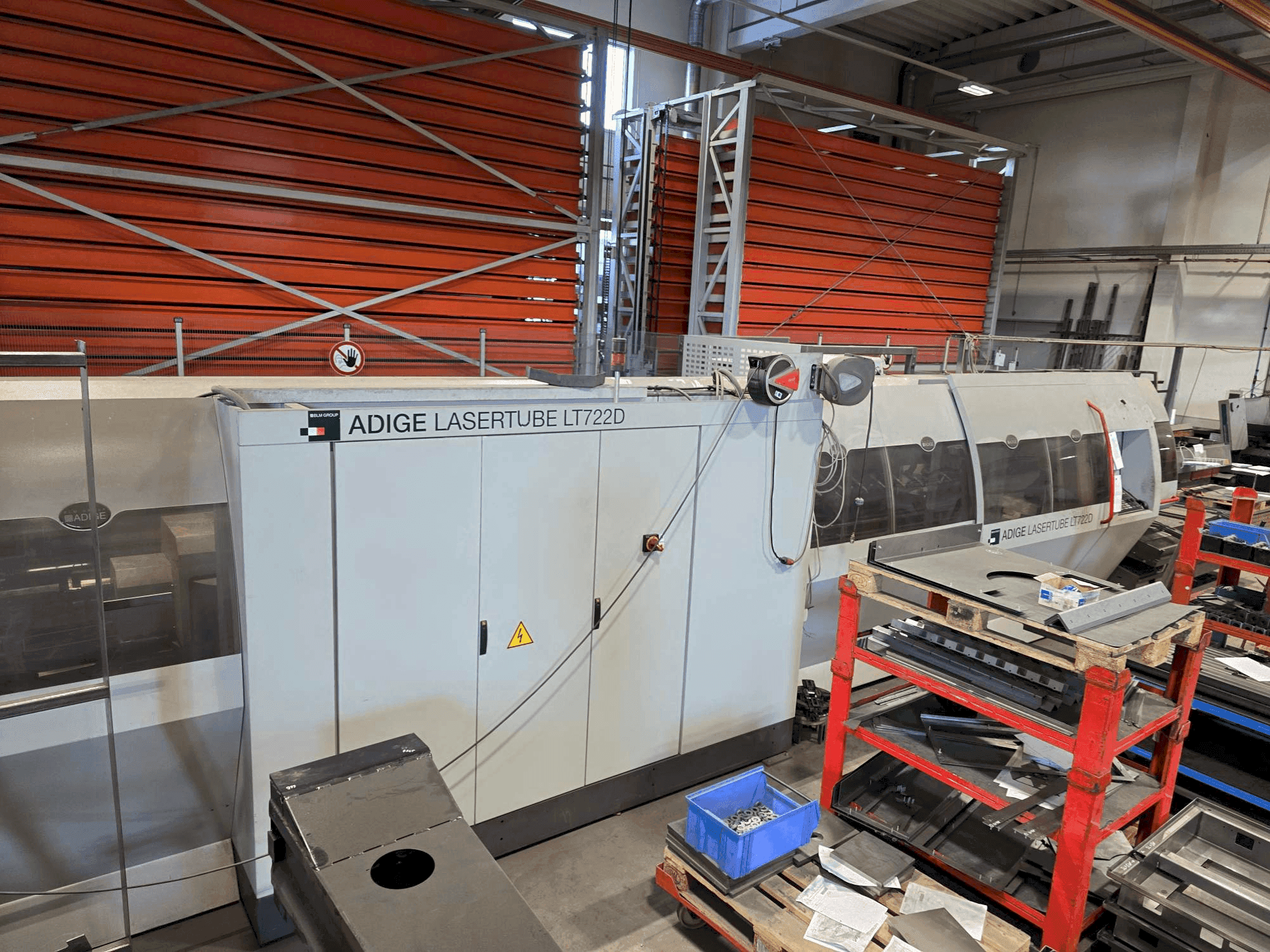

ADIGE - LASERTUBE LT722DDE-CUT-ADI-2021-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Blechbearbeitungsmaschinen

- ➤ Used ADIGE LASERTUBE LT722D For Sale | gindumac.com

This ADIGE LASERTUBE LT722D was manufactured in 2021. It's designed for laser processing of tubes, handling materials like mild steel and stainless steel. It supports various tube shapes, including round, square, and rectangular, with dimensions up to 140 mm. Features include a PRECITEC AK-HP cutting head, automatic tube bundle loader, and a robust unloading system. Ideal for high-quality laser cutting operations. Contact us for more information about this machine.

Übersicht

- Hersteller: ADIGE

- jahr: 2021

- MODELL: LASERTUBE LT722D

- Produktionsstunden: 66828

- anwendungstyp: Schneiden

- Standort: Deutschland

- maschinentyp: Faserlaserschneidmaschine

Technische Daten - ADIGE LASERTUBE LT722D

Technische Spezifikation

- Laserleistung: 2.5 kW

Zusätzliche Informationen

Semi-sealed, diffusion-cooled co2 laser source rofin dc 025 compact. Rated power: 2500 w.

Main module of the automatic unloading system with 1-cnc-axis controlled support for the tube to be machined

Program-controlled unloading

Extension module of the automatic unloading system for part lengths up to 4500 mm

Sorting of good parts to front (desk side) and rear (loader side)

Sorting of cut pieces and offcuts into a cassette

Suitable for processing open profiles (flat, l, c, and u-profiles)

Specific mechanical devices and process modifications for open profiles

Suitable for processing tubes made of mild steel or stainless steel

Round tube dimensions: Ø 12–140 mm

Square tube dimensions: 12 x 12 mm to 120 x 120 mm

Rectangular/flat-oval tube dimensions: side 10 mm up to max 140 mm

Maximum side difference for rectangular/flat-oval tubes: 110 mm

Workpiece envelope: inscribed in a Ø 170 mm circle

Maximum tube weight: 15 kg/m; 100 kg total maximum

Equipment and Unloading Device Features

Equipment for a 6.5 m bundle loader for tubes/pipes with sensitive surfaces: Rubber cladding of the chains for material feed. Plastic cladding of the tube/pipe loading and holding parts up to separation.

Main module of the automatic Unloading Device, with: 1-CNC-axis controlled support for the tube/pipe to be processed. Program-controlled unloading.

Extension module of the automatic Unloading Device for partial lengths up to 4,500 mm, with: Sorting of the good parts: To the front (console side), from 250 mm to 4,500 mm. To the rear (loader side) up to 4,000 mm. Sorting of crop ends and remnants in lengths under 250 mm into a cassette.

Tube/Pipe Specifications

Round Tubes: Diameter $\text{12 mm}$ up to $\text{140 mm}$.

Square Tubes: $\text{12 x 12 mm}$ up to $\text{120 x 120 mm}$.

Rectangular/Flat Oval Tubes: $\text{10 mm}$ side up to max. $\text{140 mm}$ side. Maximum side difference: $\text{110 mm}$. Must be inscribable in a $\text{170 mm}$ diameter circle.

Maximum Tube/Pipe Weight: $\text{15 kg/m}$ (100 kg maximal total).

Additional equipment

PRECITEC AK-HP universal cutting head holder for non-contact distance control

Capacitive distance sensor with reinforced ceramic part

Pressure resistance up to 25 bar

Mixed cooling (water and dry air) for the lens holder/upper lens area

Dry-air cooling of the ceramic part and nozzle

Automatic tube bundle loader for initial lengths between 3200 and 6500 mm

Loading with an overhead crane possible

Special lift loader equipment for square, rectangular, and flat-oval tubes

Tube separation with length measuring station

Equipment for a 6500 mm bundle loader for pipes with sensitive surfaces

Artube nesting software included

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung

Ähnliche Produkte zu ADIGE LASERTUBE LT722D

ER 4000

ERMAKSAN - Plasmaschneidemaschine

Speedy 360

Trotec - CO2-Laserschneidmaschine

FL 600 3D

TTM - Rohrschneidemaschine

MERCURY 603 1520 350W

SEI - CO2-Laserschneidmaschine

Speedy 360

Trotec - Laserschneidmaschine

TruLaser 1030

TRUMPF - CO2-Laserschneidmaschine

ByAutonom 3015

Bystronic - CO2-Laserschneidmaschine

6000V4

SPIRO - Plasmaschneidemaschine

MSF 9001.25Lr+T500 (2015)

MicroStep - Faserlaserschneidmaschine

Spark 20040

GASPARINI - Plasmaschneidemaschine

TRUMATIC L3030

TRUMPF - CO2-Laserschneidmaschine

TruLaser 8000

TRUMPF - CO2-Laserschneidmaschine