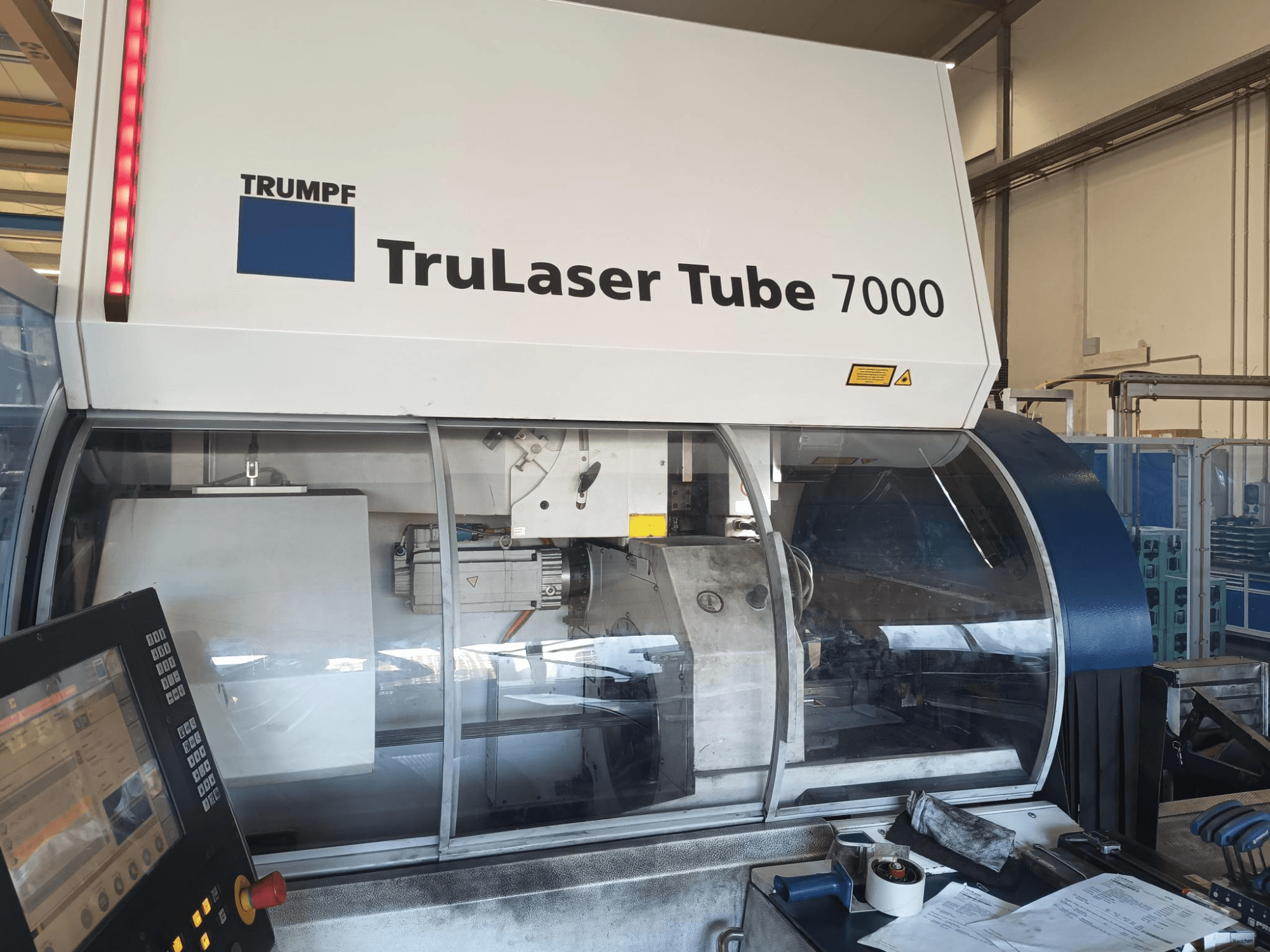

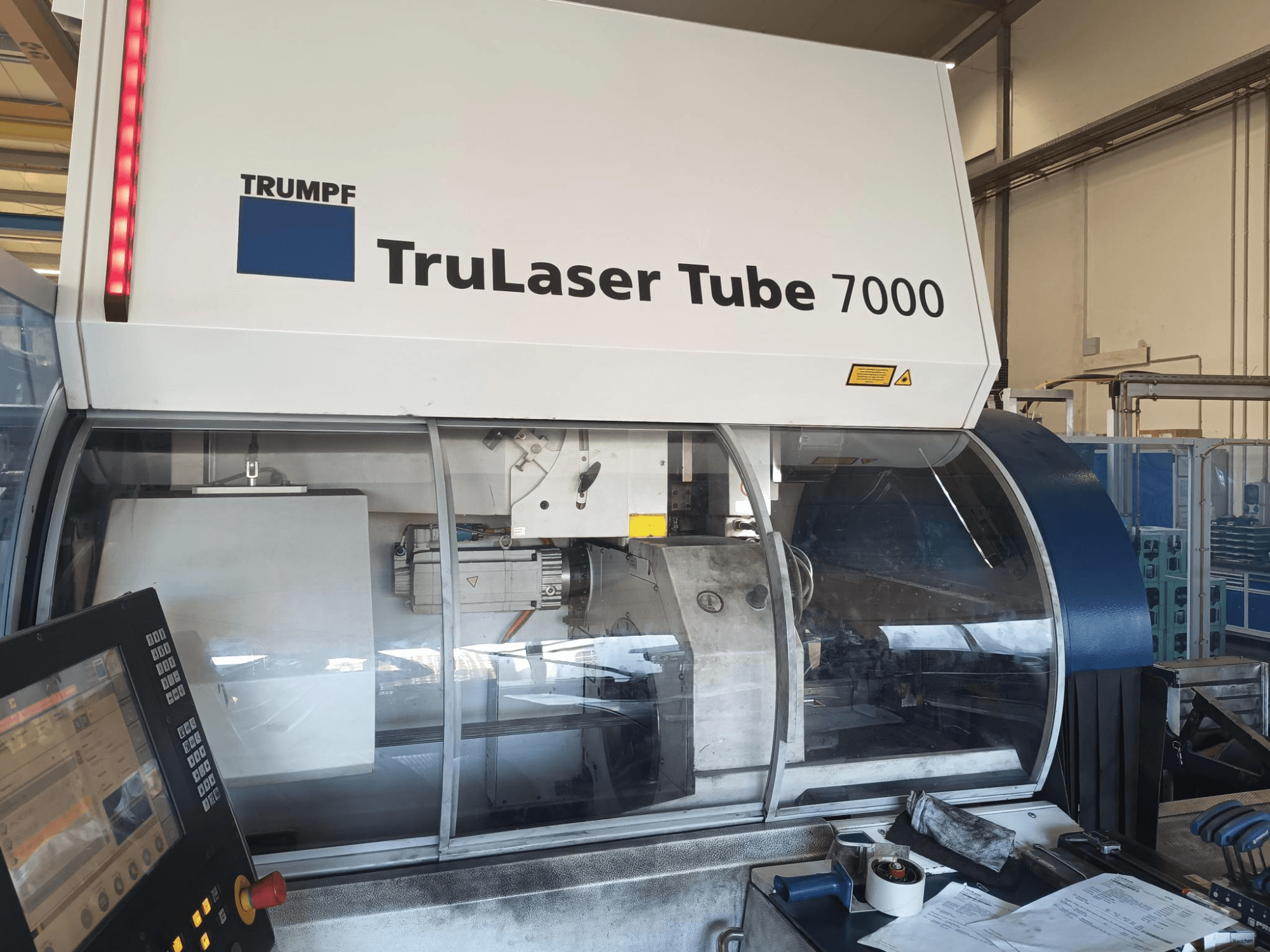

TRUMPF - TruLaser Tube 7000 KT02DE-CUT-TRU-2010-00003

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Blechbearbeitungsmaschinen

- ➤ Gebrauchte TRUMPF TruLaser Tube 7000 KT02 | Rohrabschneider

Diese TRUMPF TruLaser Tube 7000 KT02 wurde im Jahr 2010 hergestellt. Sie verfügt über einen Arbeitsbereich von 6500 mm in der X-Achse und kann Kreisdurchmesser bis zu 200 mm bearbeiten. Ausgestattet mit einem CO₂-Laser TruFlow 2000 und einem Laserschneidkopf mit 155 mm Linse ist sie ideal für das präzise Schneiden von Rohren. Kontaktieren Sie uns für weitere Informationen zu dieser Maschine.

Übersicht

- Hersteller: TRUMPF

- jahr: 2010

- MODELL: TruLaser Tube 7000 KT02

- anwendungstyp: Schneiden

- Standort: Deutschland

- maschinentyp: Rohrschneidemaschine

- Verfügbar ab: 01/08/2026

Technische Daten - TRUMPF TruLaser Tube 7000 KT02

Bewegung

- X-Achsen-Verfahrweg: 6500 mm

Zusätzliche Informationen

Kreisförmiger Durchmesser: 200 mm

Abwurfstation: 3 m mit Bürstentisch

Auswurfschale

Prozess-/Software-Merkmale: NoLine, PowerLine, ContourLine, Laserleistungssteuerung, programmierbarer Schneiddruck, Programmwiederholung, automatisches Abblasen, Arbeitsunterbrechungsbeleuchtung, Lochstechfunktion (Laser)

Laser: CO₂-Laser TruFlow 2000

Laser-Kühleinheit

Schneidkopf: Laserschneidkopf mit 155 mm Linse

Steuergerät: 84D

Konnektivität/Datenübertragung: RJ-45 Netzwerkanschluss, USB-Anschluss; Netzwerkanschluss inkl. Installation

Sicherheit: CE-Kennzeichnung, Mehrstrahl-Lichtschranken, Kondensatorleistung 1600 N/cm², Sicherheit mit Makrostopps

Zusätzliche Ausstattung

Zubehör:

Ersatzteilkoffer für Schneidköpfe

1 x Fernbedienungsset

Klemmbackensatz Ø 216 / 200 mm

U-förmige Führungsschienen für Ausscheidestation mit ID = 200 mm

Automatisierung:

LoadMaster Tube 6 m mit Bandunterstützung, 2 Greifer

Optionen für LoadMaster Tube 6 m:

Kreisförmiger Durchmesser 250 mm

Kürzere Bandunterstützung

schwenkbare Förderstrecke

Zusätzlicher Greifer Ø 200 mm

Zusätzlicher Greifer Ø 250 mm

Sonderausstattung:

Flexible Ausschleusstation 4,5 m (Prototyp) anstelle Ausschleusstation 3 m, ohne Bürstentisch

Sonderausstattung für flexible Ausschleusestation

LoadMaster (Serienausführung 103)

Einbau 100 mm höher (Einsatz von Gitterboxen möglich), Entscheidung bei Abnahme

Dienstleistungen:

Installation, Inbetriebnahme, Schulung

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung