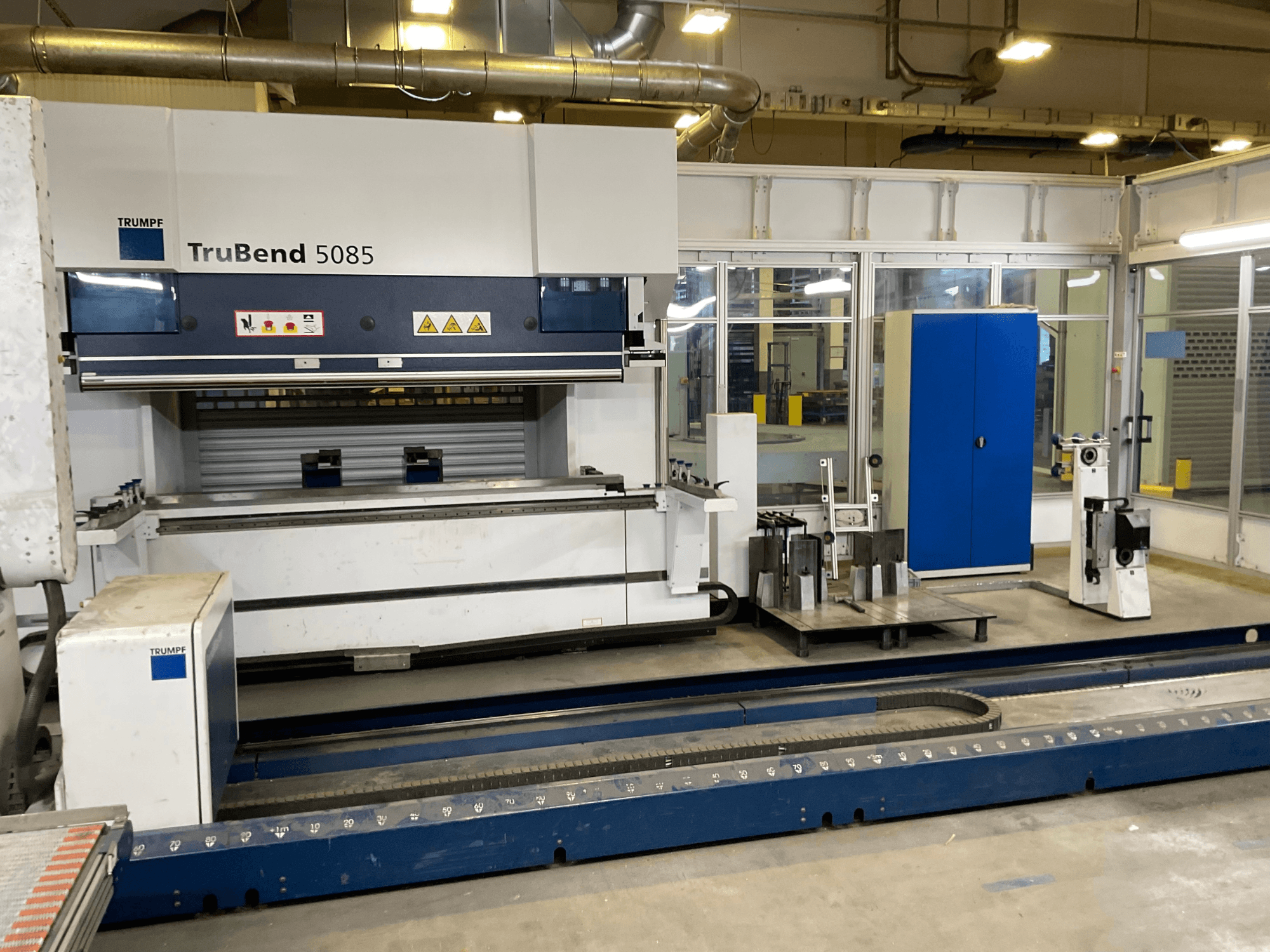

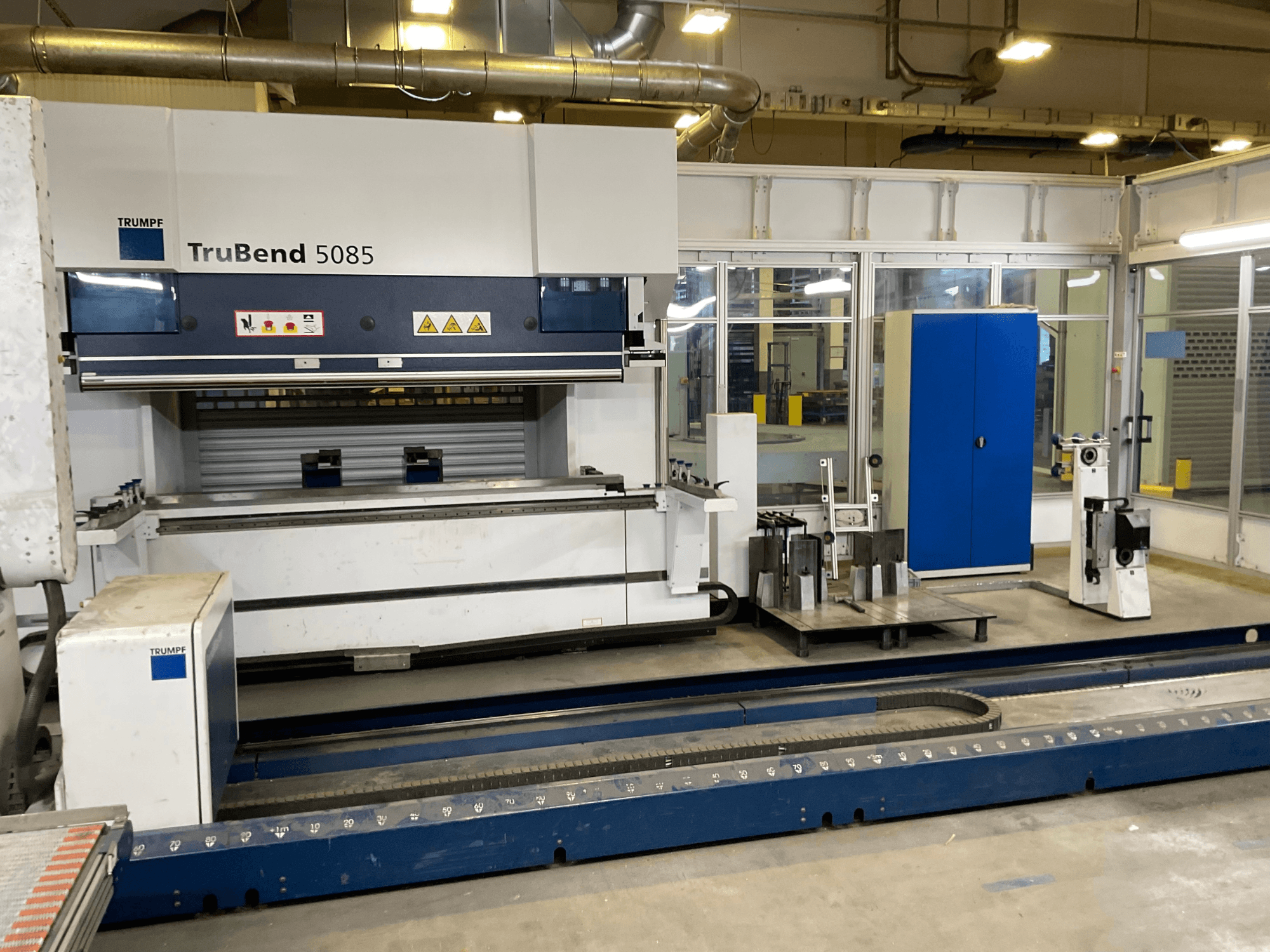

TRUMPF - TruBend Cell 500 TRUBEND Cell 5000 with TruBend 5085 extended version and BendMaster 60DE-BEN-TRU-2015-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Blechbearbeitungsmaschinen

- ➤ Used TRUBEND Cell 5000 with TruBend 5085 extended version and BendMaster 60 For Sale | gindumac.com

This TRUBEND Cell 5000 with TruBend 5085 extended version (2720 mm x 850 kN) and BendMaster 60 was manufactured in 2015. World's first bending automation with image recognition for maximum flexibility. Sheet metal parts up to 40 kg, 6-axis backgauge sensor technology. Maximum repeat accuracy thanks to angle sensor technology (ACB) in automated operation. It features a stable all-steel frame, electro-hydraulic top drive, and a modern block hydraulic system. The control unit is a TRUMPF TASC 6000 with a 15-inch touchscreen and network capabilities. Ideal for precise bending operations, consider the opportunity to buy this TRUMPF TruBend Cell 500 press brake. Contact us for more information about this machine.

Übersicht

- Hersteller: TRUMPF

- jahr: 2015

- MODELL: TruBend Cell 500 TRUBEND Cell 5000 with TruBend 5085 extended version and BendMaster 60

- Produktionsstunden: 61469

- anwendungstyp: Biegen

- Standort: Deutschland

- maschinentyp: Abkantpresse

- Marke Steuergerät: TRUMPF

Technische Daten - TRUMPF TruBend Cell 500 TRUBEND Cell 5000 with TruBend 5085 extended version and BendMaster 60

Steuerung

- Steuerungsmarke: TRUMPF

- Steuerungsmodell: TASC 6000

Zusätzliche Informationen

Machine: TruBend 5085 (2720 mm x 850 kN) with BendMaster 60

Stable all-steel machine frame

Press beam with spherical bearing and tilt adjustment

Electro-hydraulic top drive with 4-cylinder technology

Generous edge clearance

Flat front covers

Modern block hydraulics

Electronic pressure balance

Measuring system with glass scale and spring compensation

Hydraulic oil in the machine (lifetime lubrication)

Oil cooler

Control cabinet cooling via air-to-air heat exchanger

Modern machine design

Stop/Backgauge

Stop system

Backgauge system: 2 axes (X and R)

Tool clamping

Upper tool holder, manual clamping, hardened

Lower tool holder, hydraulic clamping, hardened

Lower tool shift, 2 positions, pneumatic

Crowning

Manual crowning

Control

TRUMPF TASC 6000

Graphical workshop programming

Windows XPe (embedded), Pentium 4, 2.8 GHz

2 GB RAM

15-inch touchscreen

Network-enabled

Teleservice via modem

Operation

Control panel with LCD keypad and foot switch

Communication rail

Safety

Standard safety devices

BendGuard safety device for upper tools up to 390 mm

CE marking

Additional equipment

TRUMPF BendMaster automation (standard features)

Robot/Handling

Stable base and manipulator in die-cast aluminum

Load capacity 60 kg (workpiece plus gripper)

Low-profile welded floor track

Sheet metal sensor for contour detection

Rotary feedthrough for easy gripper change

Gripper coupling on the BendMaster

Sensors for 4-axis backgauge system

Electric drives

Double sheet detection

NC gripper transfer station

Vacuum generation for suction grippers

Control

TRUMPF PC control with operator terminal

Teleservice via modem

Operation via screen, mouse, and keyboard

Safety

Safety fence with access door

World's first bending automation with image recognition for maximum flexibility Sheet metal parts up to 40 kg, 6-axis backgauge sensor technology

Maximum repeat accuracy thanks to angle sensor technology (ACB) in automated operation

TruBend 5085 (2720 mm x 850 kN) with BendMaster 60

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung