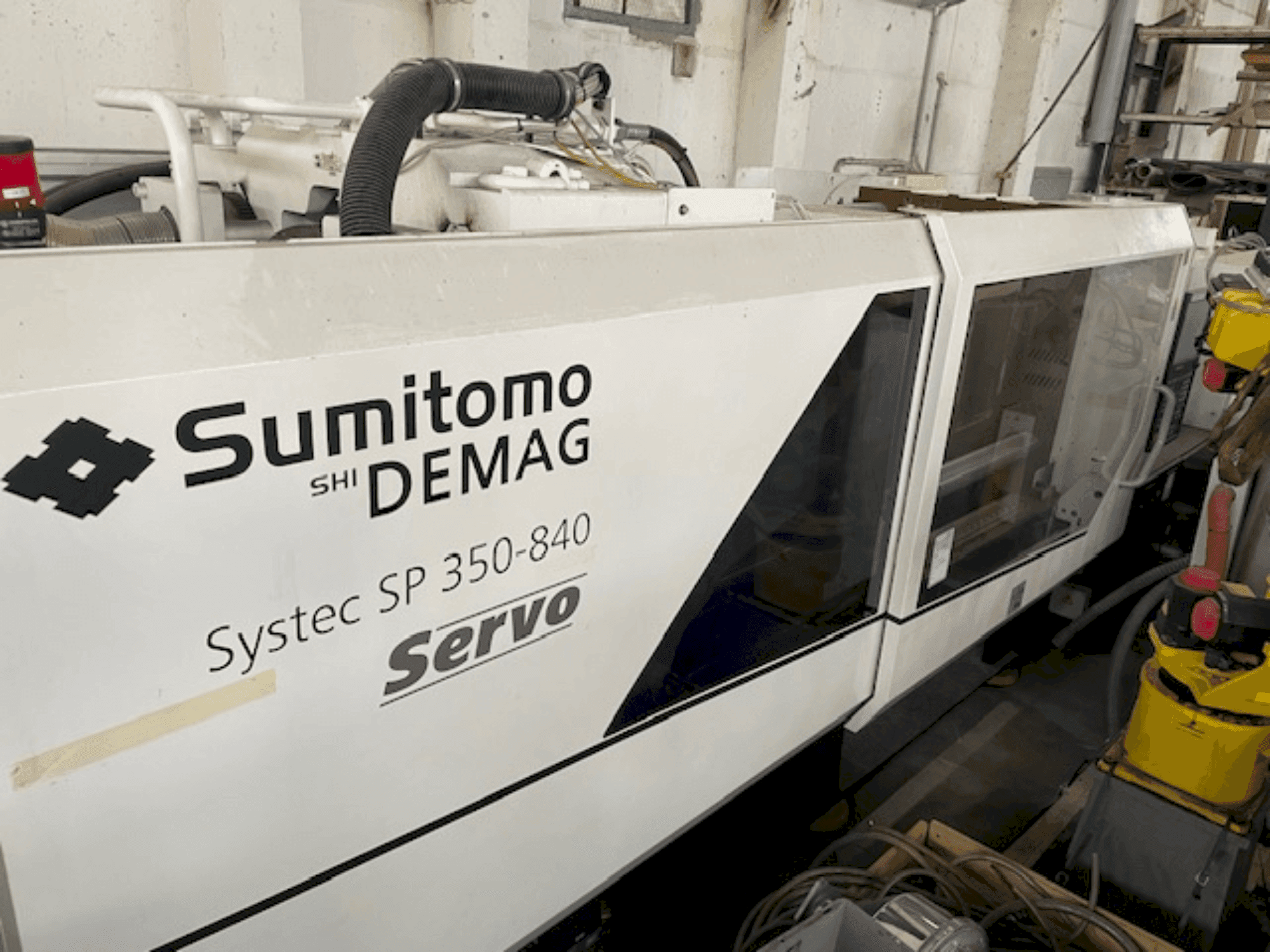

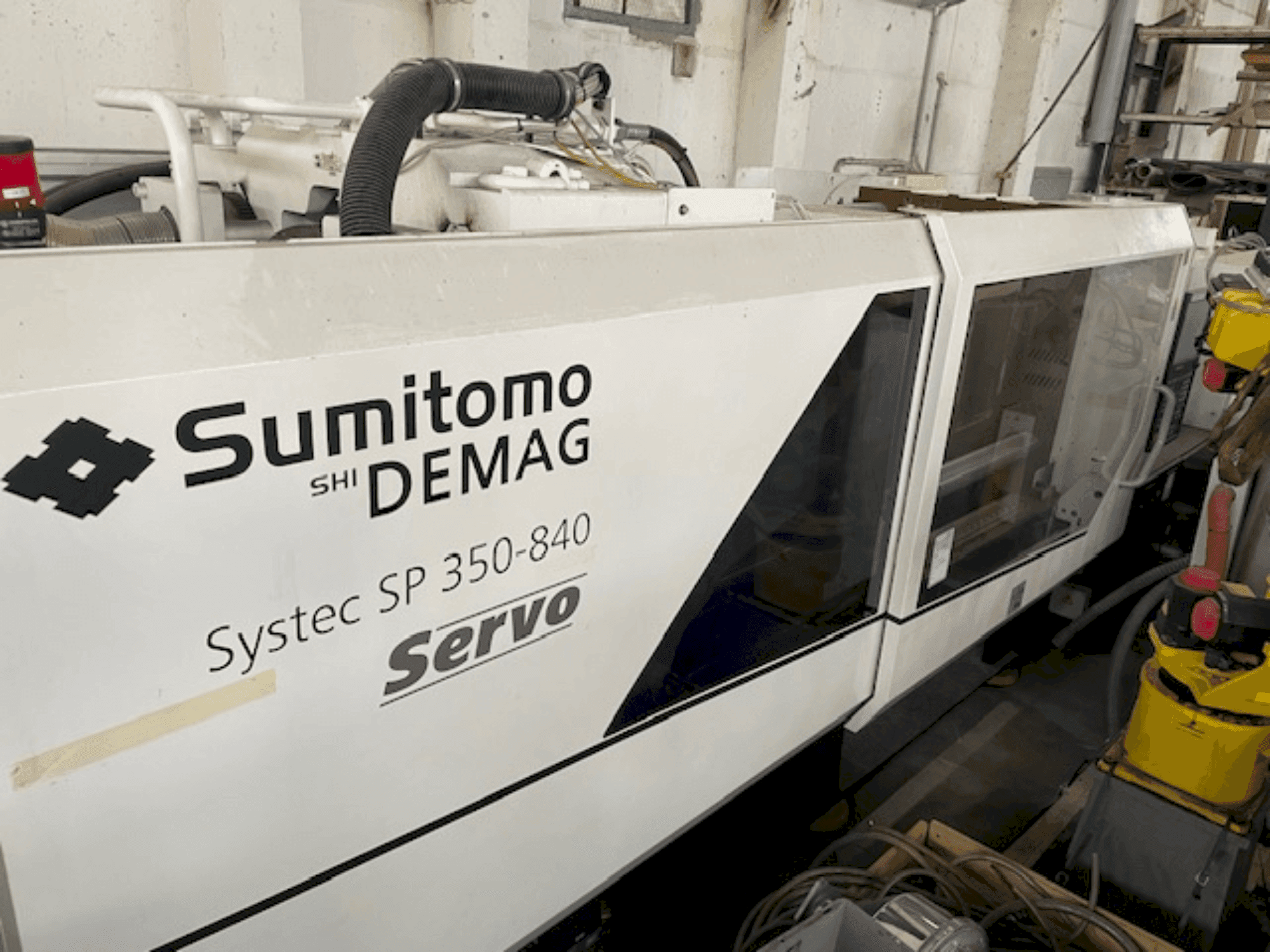

SUMITOMO SHI DEMAG - Systec SP 350/720-840DE-INJ-SUM-2015-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Produkte

- Kunststoffverarbeitungs-Maschinen

- ➤ Used SUMITOMO SHI DEMAG Systec SP 350/720-840 For Sale

This SUMITOMO SHI DEMAG Systec SP 350/720-840 was manufactured in 2015. It is a hydraulic injection moulding machine, ideal for precision plastic processing. Consider the opportunity to buy this SUMITOMO SHI DEMAG Systec SP 350/720-840 hydraulic injection moulding machine. Contact us for more information.

Übersicht

- Hersteller: SUMITOMO SHI DEMAG

- jahr: 2015

- MODELL: Systec SP 350/720-840

- Produktionsstunden: 15642

- anwendungstyp: Spritzgießen

- Standort: Deutschland

- maschinentyp: Hydraulische Spritzgießmaschine

Technische Daten - SUMITOMO SHI DEMAG Systec SP 350/720-840

Maße

- Maschinenbreite: 6950 mm

- Maschinenhöhe: 2213 mm

- Maschinengewicht: 15750 kg

Technische Spezifikation

- Schraubendurchmesser: 45 mm

Zusätzliche Informationen

Additional equipment

- Fanuc Robot

Machine Benefits

Qualitative Machine Benefits

- Process data acquisition, mould protection

Technical Machine Benefits

- Mould height min: 350 mm / mould height max: 745 mm

- Main electronic connection: 3/400 v 50hz

- Programmable sequence, highly dynamic feed speed, hydraulic pressure-dependent holding pressure control, digital/wear-free position measuring system.

Extra Information

Standard equipment: Support of the moving mould mounting platen via linear guides/ Ejector short / long stroke/ Interface for external printer (hardcopy)/ Individual axis movement optimization (activeAdjust)/ Four-stage mould closing and four-stage mould opening sequence/ Pump drive power II, increased (59.0 kW)/ Mains voltage 400 V ±10% / 50 Hz, 3 phases + N + PE/ Mains connections drive / heating separate/ Data display coloured/ Oil cooler reinforced (cooling water supply up to 35 °C)/ Water connection for mould and machine cooling separate/ Basic version Europe/ Corrosion protection/ Paint finish: Deep black (RAL9005): Machine bed with internals, lower switch cabinet/ Signal white (RAL9003): Clamping unit, injection unit, nozzle guard/ Signal white (RAL9003): Fixed safety devices, upper switch cabinet/ Signal white (RAL9003): Safety doors/ Textured surfaces: Elastic machine bearings/ Digital and wear-free position measuring system (ultrasound/high-resolution rotary encoders for injection, mould and ejector movement)/ Mould connection dimensions type E (according to EUROMAP March '96)/ Centring diameter fixed platen: 160 mm/ Centring diameter moving platen: 160 mm/ Without side ejector plate/ Standard mold installation height: Min: 350 mm/ Max: 745 mm/ Standard closing speed (movements only when safety gate is closed)/ Ejector with position control (p/F+v independently programmable, parallel to mold movement)/ Toggle lever oil lubrication/ Injection unit/ Optional equipment: Speed-controlled pump Servo Technology (activeDrive)/ Emergency stop switch on operator side/ Separate opener for ultra-fine filtering in the bypass (activeCool&Clean)/ Socket 1 x Schuko (230V / 10A), can be disconnected via main switch/ Socket IECEE 3Ph / 400V-16A, can be switched off via main switch/ Flashing light/ Operation with safety door open (operator side)/ 6 pneumatic 5/2-way valves on movable tool plate (programmable)/ 6 pneumatic 5/2-way valves on fixed tool plate (programmable)/ Central maintenance unit for pneumatic valves/ Core pull 1-circuit via proportional valve (programmable, with non-return valves)/ Manual pressure relief for core pull 1-circuit/ Protective clothing on operator side widened (250 mm)/ Hot runner control 12 zones, integrated (2, 75 kW)/ Pneumatic hot runner nozzle control (1x 5/2-way valve)/ Clamping force control/ Active mold protection via sensor when closing (activeQ)/ Manually adjustable monitoring switch for mold open position/ Central grease lubrication (manual)/ Material hopper for automatic filling/ Hopper shut-off with emptying option/ Holding pressure switchover dependent on hydraulic pressure (with pressure recording)/ Nozzle contact pressure when mold is open (programmable)/ Nozzle movement parallel to closing movement/ Screw position-controlled (high-speed)/ 2 freely programmable screens/ Special equipment: Cooling water manifold 2x 8-way (mounted on fixed and movable plate)/ Connections: G1/2" internal thread, ball valves/ Max. Flow rate: 17 m³/h (at 60°C / 8 bar)/

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Borja Garcia

Zahlungsoptionen

Vorkasse

Asset-Finanzierung