Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

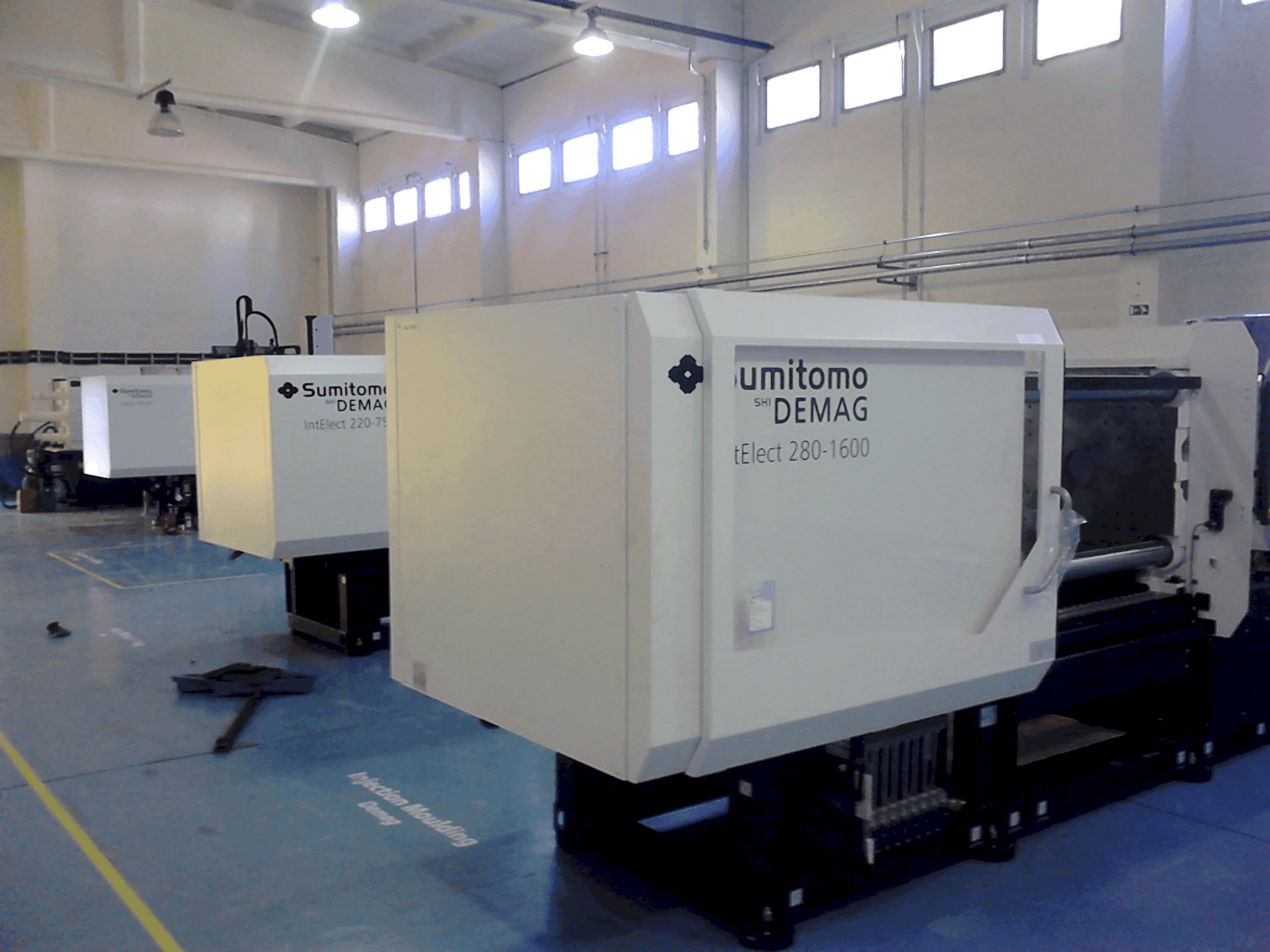

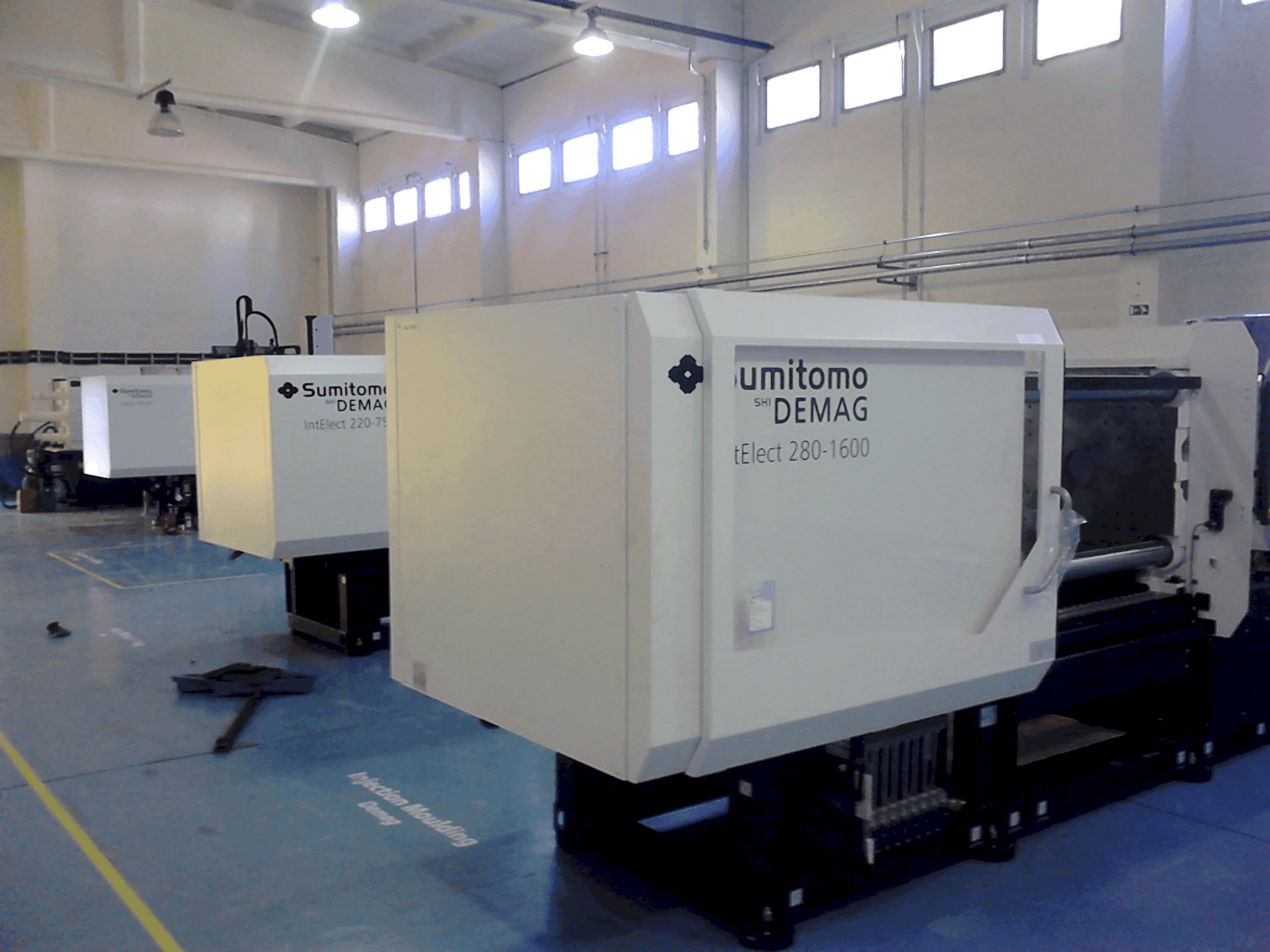

SUMITOMO SHI DEMAG - Intelect 280/685-1600DE-INJ-SUM-2013-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Produkte

- Kunststoffverarbeitungs-Maschinen

- ➤ Used SUMITOMO SHI DEMAG Intelect 280/685-1600 For Sale

This SUMITOMO SHI DEMAG Intelect 280/685-1600 was manufactured in 2013. It is an electrical injection moulding machine known for its precision and efficiency. Ideal for complex moulding tasks, this machine represents a significant asset for any production line. Consider the opportunity to buy this SUMITOMO SHI DEMAG Intelect 280/685-1600 electrical injection moulding machine. Contact us for more information.

Übersicht

- Hersteller: SUMITOMO SHI DEMAG

- jahr: 2013

- MODELL: Intelect 280/685-1600

- Produktionsstunden: 26625

- anwendungstyp: Spritzgießen

- Standort: Deutschland

- maschinentyp: Elektrische Spritzgießmaschine

Technische Daten - SUMITOMO SHI DEMAG Intelect 280/685-1600

Maße

- Maschinenbreite: 7250 mm

- Maschinenhöhe: 2030 mm

- Maschinengewicht: 13700 kg

Technische Spezifikation

- Klemmkraft: 2800 kN

- Schraubendurchmesser: 50 mm

Zusätzliche Informationen

Additional equipment

- Included with Sepro Robot SDR 22

Machine Benefits

Technical Machine Benefits

- Maximum projection of the drive with nozzle lift-off: 39 mm

- Clamping unit: 280

- Locking force: 3080 kn

- Maximum platen distance: 1220 mm

- Mold mounting platens (h x v): 950 x 885 mm

- Clear column distance (h x v): 685 x 635 mm

- Injection unit: 1600

- L/d ratio: 20

- Injection flow (ps) without accumulator: 314 cm³/s

- Metering stroke: 285 mm

Extra Information

Maximum Nozzle Travel: 450 mm Nozzle Immersion Depth (SVO): 20 mm Material Hopper Capacity: 110 l Maximum Injection Speed, Standard: 160 mm/s/ Standard equipment: Power supply: 400 V ±10% / 50 Hz, 3 phases + N + PE/ Cable connections: Common for drive and heating/ Data display: Colored display/ Water connections: Separate connections for mold and machine cooling/ Basic configuration: Europe-specific/ Color: Machine bed with pump station, electric motor, lower control cabinet: Jet Black (RAL9005)/ Clamping unit, injection unit, nozzle safety devices: Signal white (RAL9003)/ Safety doors and fixed covers: Signal white (RAL9003)/ Textured surfaces: Cooling system: Open circuit/ Anti-vibration feet/ Mould platen layout: Type E (according to EUROMAP March '96), without lateral ejector plate/ Standard mould height/ Closing speed: Movements only when safety guard is closed/ "Force" function: For long holding pressure times, max. injection speed: 160 mm/s Injection speed: 160 mm/s/ Temperature control: Closed control loop for feed zone (max. 90°C + 9°C tolerance)/ Back pressure: Programmable via 6 base points (polygon)/ Closed control loop for injection, holding pressure, back pressure and dosing/ Nozzle sealing force: Programmable when mould is closed/ Screw & barrel: Wear-resistant screw/ Nitrided barrel/ Standard L:D ratio/ Screw diameter: 50 mm/ Non-return valve: 3-part ring version/ Nozzle: Open design/ Metric thread: M60x3/ Radius: 15.0 mm, bore: 3.0 mm/ Optional equipment: Emergency stop button on the non-operator side/ Socket: 1 x Schuko (230V / 10A), can be switched off via main switch/ Flashing light/ Pneumatic valves: 2 x 5/2-way valves on the fixed platen, programmable/ Cooling water controller: 4 circuits with temperature display (max. 10 l/min per circuit) Mold cooling: Time-programmable shutdown 10 l/min per circuit)/ Mould cooling: Switch-off time programmable/ Hot runner control: Integrated (5 zones, 2.75 kW)/ Clamping force control: Closed control loop/ Active mould protection via sensor when closing/ Material hopper for automatic feeding/ Switchover to holding pressure depending on melt pressure or injection force

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Borja Garcia

Zahlungsoptionen

Vorkasse

Asset-Finanzierung