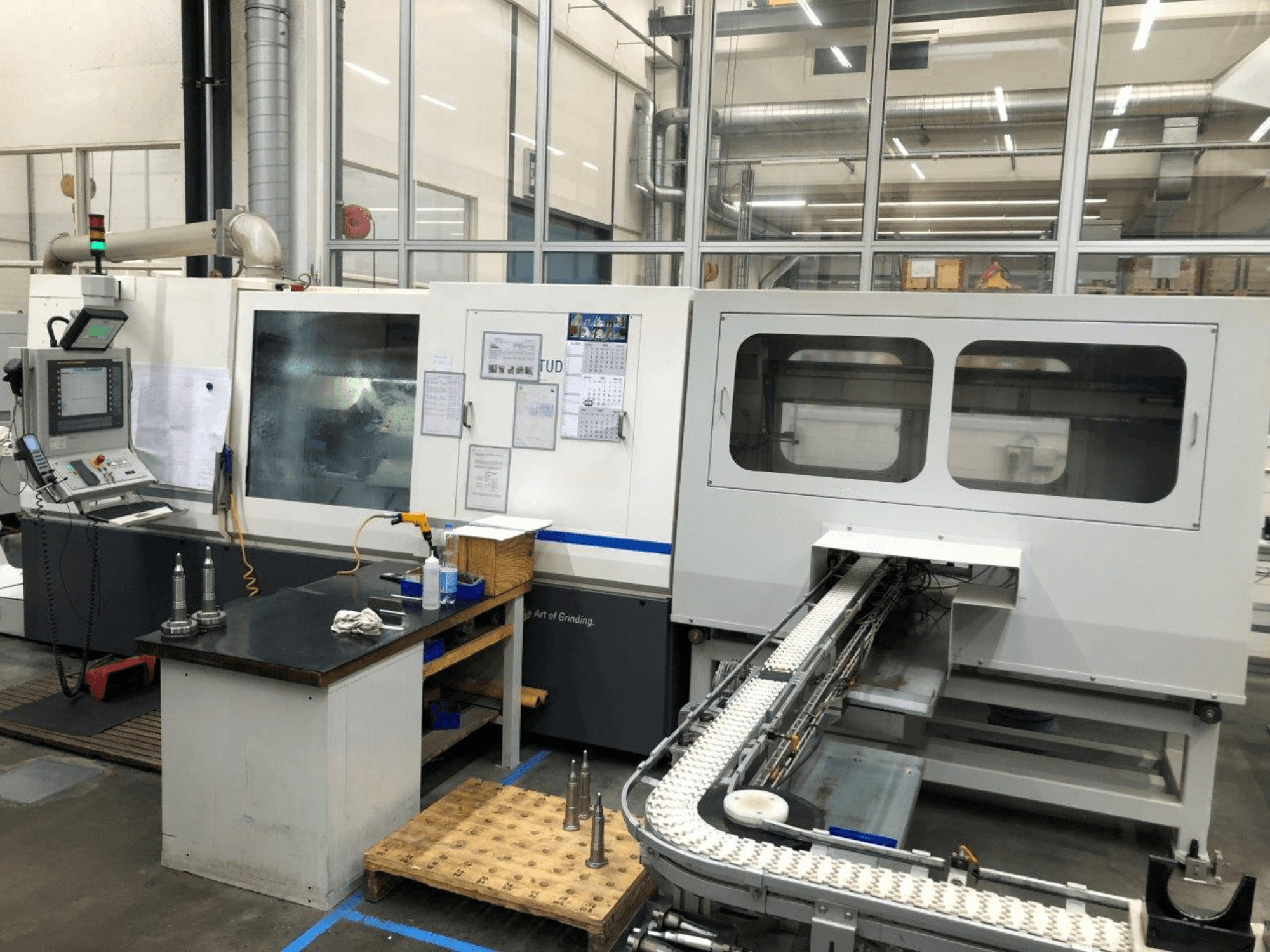

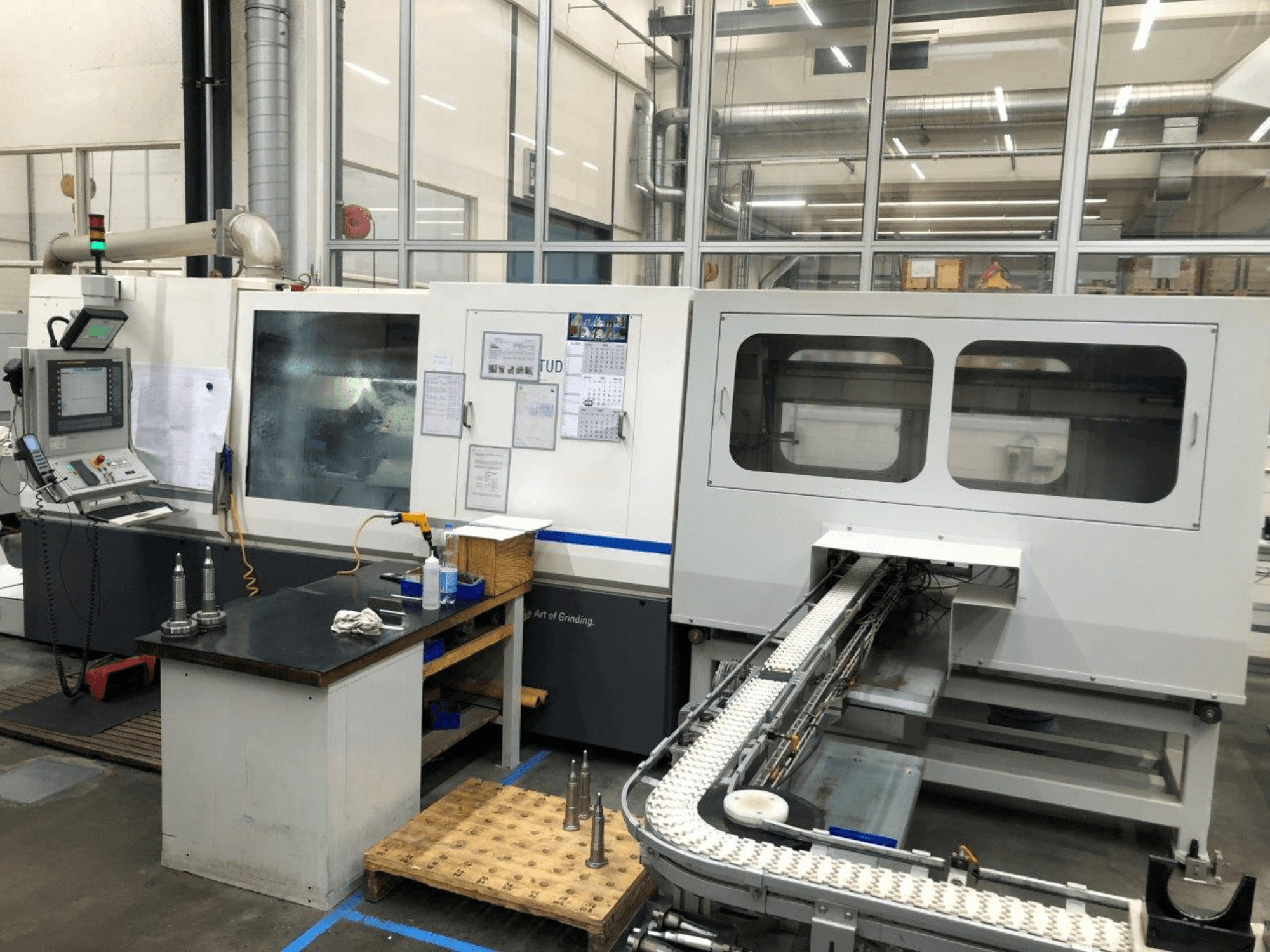

STUDER - S242CH-GRI-STU-2008-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- ➤ Gebrauchte STUDER S242 zu verkaufen | gindumac.com

Diese STUDER S242 wurde 2008 hergestellt, eine Rundschleifmaschine, die für ihre Robustheit und Präzision bekannt ist. Sie hat einen Umlaufdurchmesser von 180 mm, ein maximales Werkstückgewicht von 20 kg und eine Schleifspindelgeschwindigkeit von bis zu 50 m/s. Die Maschine verfügt über eine Wellenautomatisierung und Schleifscheiben und ist noch voll funktionstüchtig und eingeschaltet. Die jährliche Wartung durch Studer gewährleistet die Zuverlässigkeit. Für weitere Informationen zu dieser Maschine nehmen Sie bitte Kontakt mit uns auf.

Übersicht

- Hersteller: STUDER

- jahr: 2008

- MODELL: S242

- anwendungstyp: Schleifen

- Standort: Schweiz

- maschinentyp: Rundschleifmaschine

Technische Daten - STUDER S242

Maße

- Maschinengewicht: 12000 kg

Bewegung

- X-Achsen-Verfahrweg: 450 mm

- Z-Achsen-Verfahrweg: 850 mm

Zusätzliche Informationen

Achsabstand: Klein (2 Querschlitten) 400 mm; Lang (2 Querschlitten) 800 mm; Lang (3 Querschlitten) 800 mm

Schwenkdurchmesser: 180 mm

Max. Werkstückgewicht: 20 kg

X-Achse (Querschlitten)

Geschwindigkeit: 0,001-1.500 mm/min

Auflösung: 0,00001 mm

Z-Achse (Längsschlitten)

Max. Verfahrweg: 850 / 1.600 mm

Geschwindigkeit: 0,001-25.000 mm/min

Auflösung: 0,00001 mm

Drehbarer Revolver

8-Stationen: Capto 6 feststehend

12-Stationen: VDI 40 feststehend

8-Stationen: VDI 30 angetrieben feststehend

Max. Antriebsdrehzahl: 4.000 U/min

Antriebsleistung: 2,5 kW

Option: Aktiver Längsmessstab am Revolver (Capto oder VDI)

Schleifspindelkopf

Montagewinkel: -25° / +25°

Schleifgeschwindigkeit: 50 m/s

Größe der Schleifscheibe: Ø 400 x 50 (63) x 127 mm

Innenschleifeinrichtung

Spindelpositionen auf dem Schwenkteller: 3

Stellung der Spindel: 0° / +45°

Automatische Positionierung in 3 Positionen

Bereich der Innenschleifspindel: 1.200-120.000 U/min

Verfügbare Spindeldrehzahlen: 24.000-120.000 U/min

Werkstückspindelkopf (fest)

Drehzahlbereich: 1-7.500 min-¹

Antriebsleistung: 10,5 kW

Werkzeugaufnahme: MK4 / DIN 55026 A4

Belastung beim Flachschleifen: 500 Nm

Rundheitsgenauigkeit: 0,0004 mm

Werkstückspindelstock (schwenkbar)

Schwenkbereich: 0-10°

Auflösung: 0.0001°

Drehzahlbereich: 1-4.000 min-¹

Antriebsleistung: 10,5 kW

Werkzeugaufnahme: MKS / DIN 55026 A6

Belastung beim Flachschleifen: 500 Nm

Rundheitsgenauigkeit: 0,0004 mm

W-Achse / Reitstock

Max. Verfahrweg: 450 / 1.650 mm

Geschwindigkeit: 0,001-1.500 mm/min

Feineinstellung für Zylindrizitätskorrekturen: ±0,01 mm

Option: Pinole Rücklauf ±0,40 mm

Pinole Durchmesser: 60 mm

Aufnahmekonus: MK4

Pinolenweg: 45 mm

Optionaler Synchron-Reitstock: 1-7.500 U/min; Antriebsleistung 10,5 kW; Aufnahmekegel MK4 / DIN 55026 A4

Abrichten

Stehendes Abrichtwerkzeug, Halter mit MK1-Aufnahme

Einpunkt-Diamant / verkürzte Fliese

Abrichtspindel mit Axialantrieb auf schwenkbarem Halter: Ø 58 / 89 / 100 mm max

Abrichtspindel mit Axialantrieb auf der Rückseite: Ø 100 mm max

Anschlusswerte

Anschlussleistung gesamt: 45 kVA

Minimaler Luftdruck: 5,5 bar

Gesamtgewicht: 7.600 / 12.000 kg

Zustand und Wartung

Noch eingeschaltet und voll funktionsfähig

Keine Schrupparbeiten

Jährliche Wartung durch Studer

Zusätzliche Ausrüstung

Wellenautomation (im Lieferumfang enthalten)

Schleifscheiben (im Lieferumfang enthalten)

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung