Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

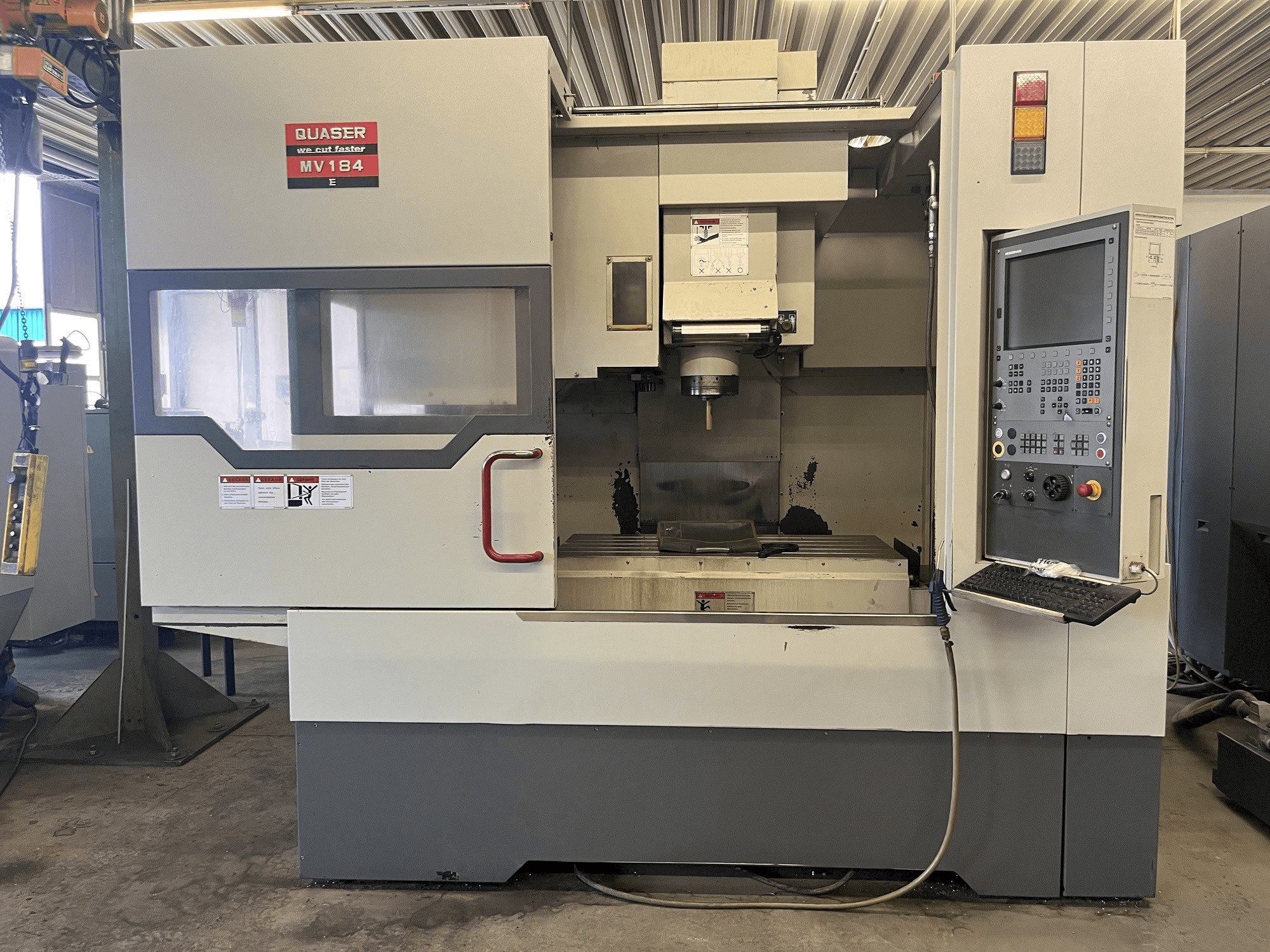

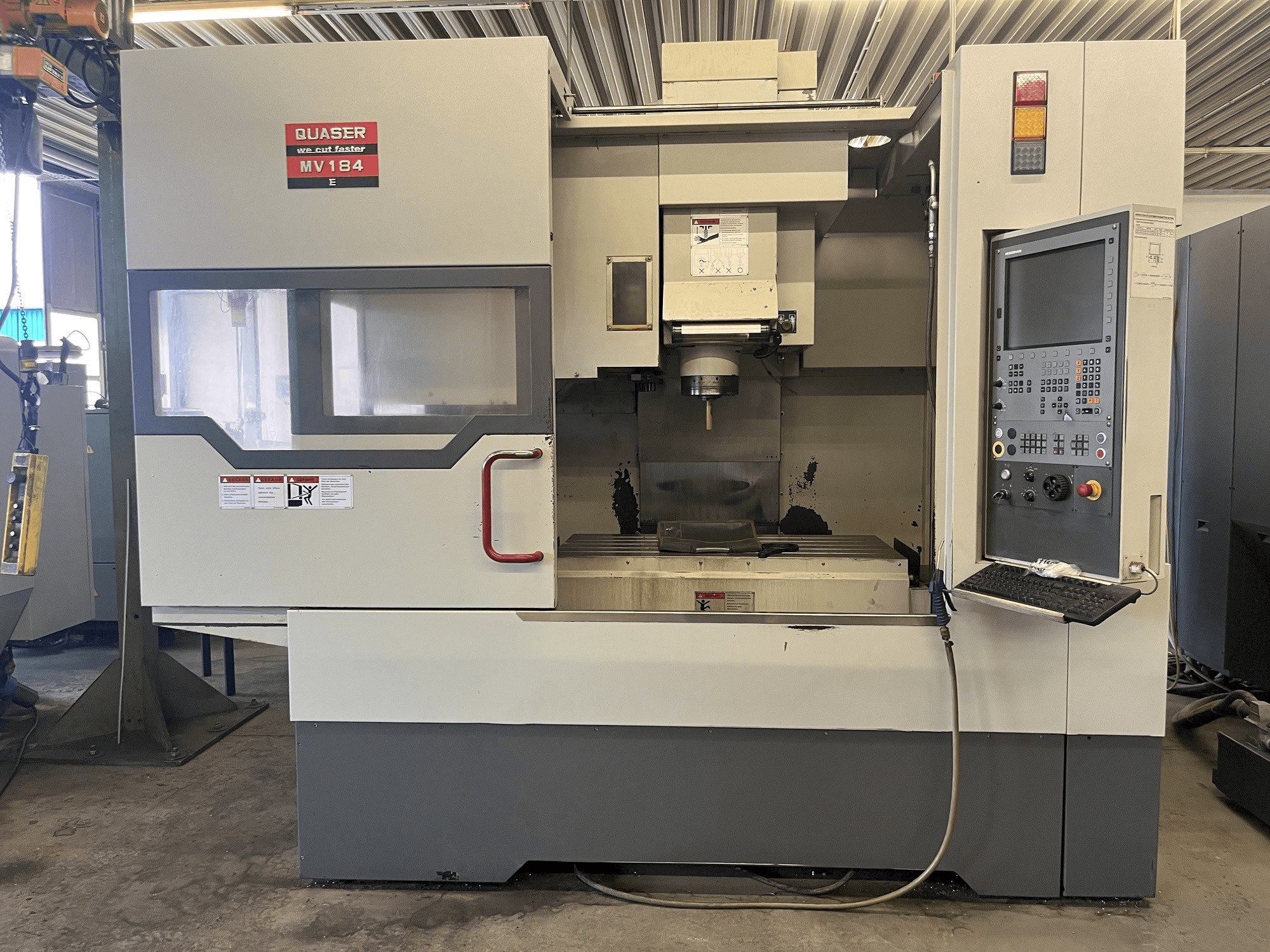

Quaser - MV 184EDE-MIL-QUA-2009-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- Quaser MV 184E Vertikales Bearbeitungszentrum

Dieses Quaser MV 184E Vertikal Bearbeitungszentrum wurde im Jahr 2009 hergestellt. Sie ist mit einer Heidenhain iTNC 620 Steuerung ausgestattet und hat 3. Die Maschine hat eine Spindeldrehzahl von 30 - 12000 U/min.

Übersicht

- Hersteller: Quaser

- jahr: 2009

- MODELL: MV 184E

- anwendungstyp: Fräsen

- Standort: Deutschland

- maschinentyp: Vertikal-Bearbeitungszentrum

- Marke Steuergerät: HEIDENHAIN

Technische Daten - Quaser MV 184E

Steuerung

- Steuerungshersteller: HEIDENHAIN

- Steuerungsmodell: iTNC 620

Maße

- Maschinenbreite: 2920 mm

- Maschinenhöhe: 2860 mm

- Maschinengewicht: 6790 kg

- Tischlänge: 1200 mm

- Tischbelastung: 7 kg

- Tischbreite: 600 mm

Bewegung

- Anzahl der Achsen: 3

- X-Achsen-Verfahrweg: 1020 mm

- Y-Achsen-Verfahrweg: 610 mm

- Z-Achsen-Verfahrweg: 610 mm

Technische Spezifikation

- Spindelleistung: 17 kW

- Spindeldrehzahl: 12000 RPM

Zusätzliche Informationen

Zusätzliche Ausrüstung

- Späneförderer

Maschinenvorteile

Qualitative Maschinenvorteile

- Kühlsystem für die hauptspindel mit separatem Ölkühlkreislauf 100 1 und luftzufuhr für den hauptmotor

- Vorgespannte kugelumlaufspindeln durchm. 45 mm

- Werkzeughalter nach din 69871 (bt 40 oplion), werkzeugspannbolzen nach din 69872 (iso) 7388 option)

- Späneentsorgung, bestehend aus 2 schneckenförderern und sptllsyslem im arbeitsbereich, sowie kratzbandförderer

- Kühlmitteltank mit 300 l fassungsvermögen

- Flutkühlung, mit 12 verstellbaren austrittsdüsen in einem ring auf der spindelnase, förderleistung 60 1/min bei 2 bar palron filter 80 µ für spänespülung und flutkühlung

- Innere kühlmittelzufuhr mit grundfoss pumpe 20 bar. 251/min, inkl. Patronenfilter 25 µ

- Spänespülung mit grundtoss pumpe 60 1/min bei 2 bar, spänewannen aus edelstahl im arbeitsraum

- Arbeitsraum vollschutz mit großen sichttüren (türöffnung 900 mm) und 2 arbeitsraumleuchten, sowie maschinenstatusleuchte

- Gebläseluft, extern. Für die trockenbearbeitung

Technische Maschinenvorteile

- Innere kühlmittelzufuhr 20 bar

- Anzahl der werkzeuge im magazin 30 stück

- Werkzeughalter sk 40

- Doppelarmiger werkzeugwechsler mit 30 speicherplätzen

- Groß dimensionierte linearführungen in allen achsen

- Hochdynamische digitale vorschubantriebe mit 6800 n (z 13900 n) achsleistung

- Computer-optimierter, schwerer maschinenkörper aus stark verripptem gusseisen

- Eilgang 32 rnlmin (z ;24 mlmin), beschleunigung {x/y/z) 3/3 /3 m/sec'

- Drehmoment 108 nm

- Siemens-weiss hauptspindel sk 40, geeignet für standardvorrichtungen und werkzeuge mit plandrehsystem

Zusätzliche Informationen

Kühlmittel-Spritzpistole. - Zweifarbige Lackierung in Hellgrau/Grau. - Glasmaßstäbe für X-. Y- und Z-Achse (HDH) mit Überdruck, um eine Verschmutzung des direkten Messsystems zu verhindern. - Automatische Zentralschmierung für die Kugelumlaufspindeln. - Quaser Bearbeitungszentren entsprechen den CE-Normen.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung