Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

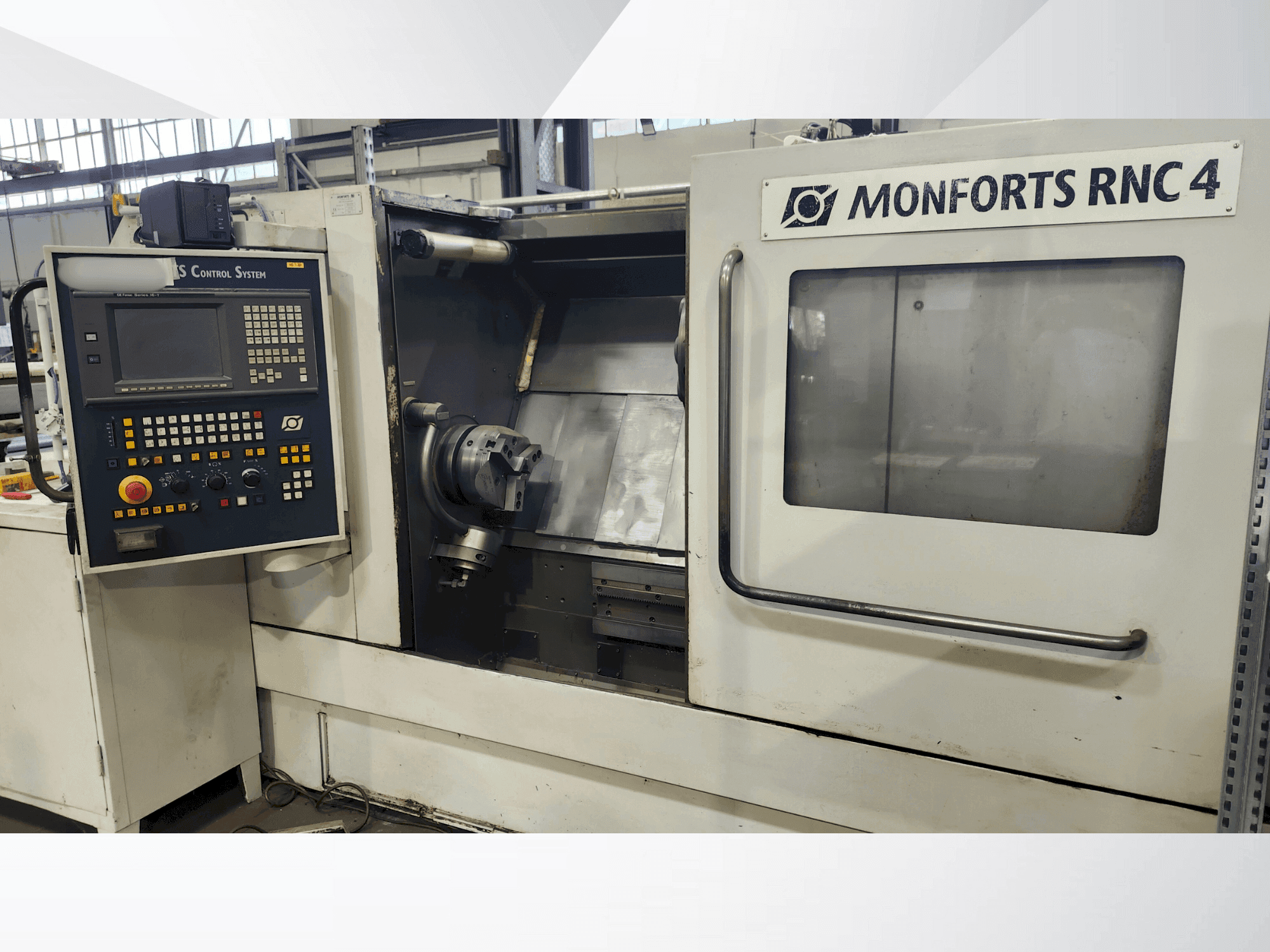

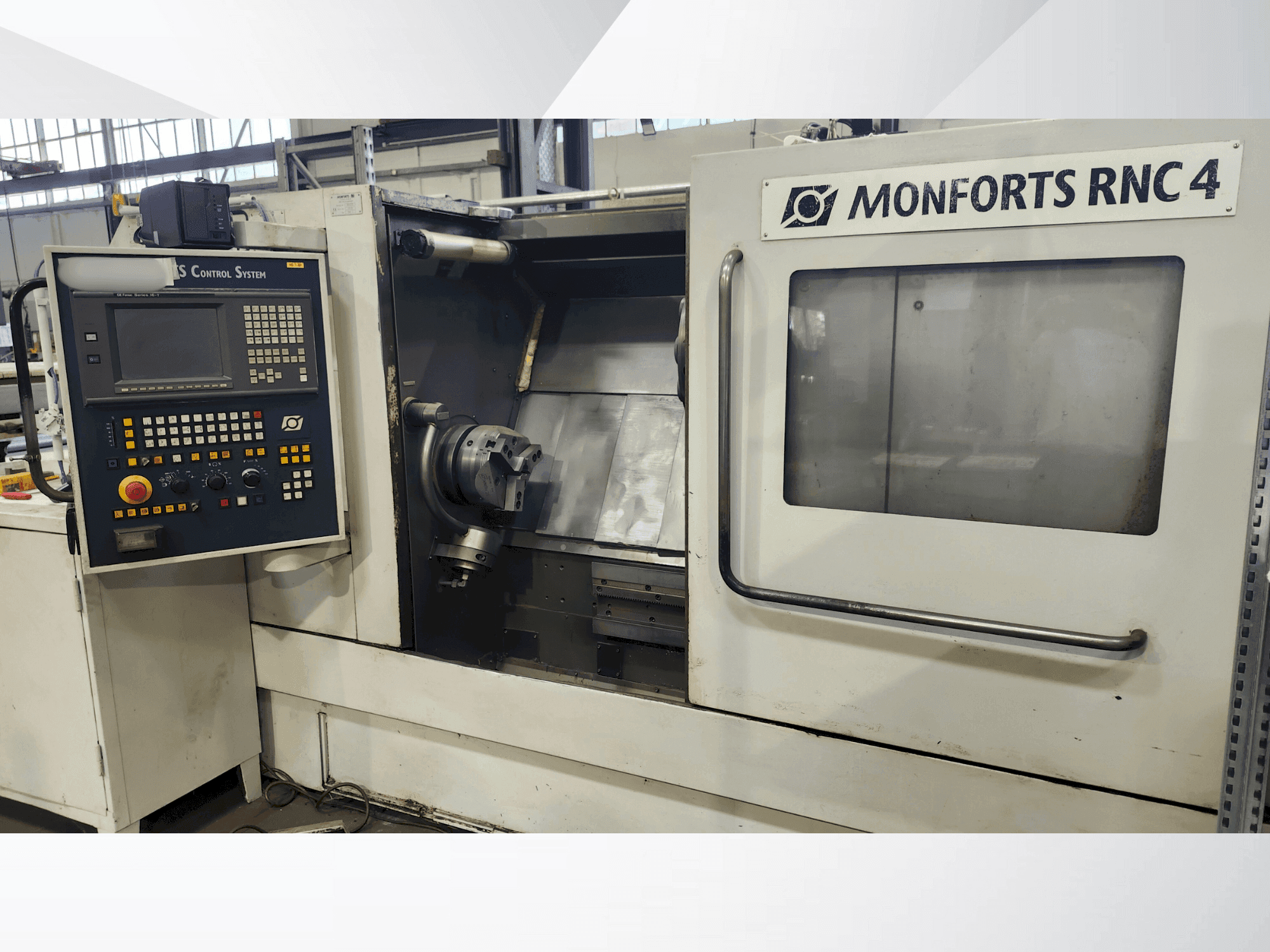

Monforts - RNC 4CH-TUR-MON-1997-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- ➤ Used Monforts RNC 4 For Sale | gindumac.com

This Monforts RNC 4 was manufactured in 1997. It operates on a 400 V mains voltage and comes with various tools included. This horizontal turning machine represents a solid choice for those looking to enhance their machining capabilities. Contact us for more information about this machine.

Übersicht

- Hersteller: Monforts

- jahr: 1997

- MODELL: RNC 4

- anwendungstyp: Drehen

- Standort: Schweiz

- maschinentyp: Horizontal-Drehmaschine

- Marke Steuergerät: FANUC

Technische Daten - Monforts RNC 4

Steuerung

- Steuerungsmarke: FANUC

- Steuerungsmodell: n/a

Zusätzliche Informationen

Machine Benefits

Technical Machine Benefits

- Various tools included, see pictures

Extra Information

Machine still under power // Working area: Swing over bed: 420 mm/ Swing over radial slide: 280 mm/ Turning length: 600 mm/ Spindle diameter in front bearing: 130 mm/ Spindle mount: DIN 55026 A6/ Material throughput: 65 mm/ Main drive: Three-phase direct drive (100% duty cycle / 50% duty cycle): 18.5 / 22 kW/ Speed range: 44 – 4000 rpm/ Torque: 346 / 411 Nm/ Feed drive: Three-phase servo drives with electronic safety monitoring/ Rapid traverse speed X/Z axis: 24 / 30 m/min/ Feed force X-axis: 6.4 kN/ Feed force Z-axis: 10.4 kN/ Tool turret: 12 tool holders according to DIN 69880 (VDI) 3425/2)/ Shaft diameter: 40 mm/ Control: MONFORTS Control System MCS F (Version 16T)/ With AC servo and digital spindle drives./ Features: 32-bit processor and bus/ Measuring circuits for 2 axes and 1 spindle (expandable up to 8 axes / 2 spindles)/ Integrated, freely programmable interface control/ Operator panel components: High-resolution color screen with tool path display (with/without machine movement)/ Softkey / Diagnostic system for service/ Integrated machine control and handheld control panel/ Basic CNC equipment: Program memory: approx. 256 KB/ Max. 63 programs in memory (expandable to 1000)/ 64 tool data memories, separate for length and wear/ Simultaneous program input during machining/ Cutting radius compensation/ Machining and thread-cutting cycles (four-cycle cycles)/ Subroutines (4-way nesting)/ Copying and mixing of programs/program sections/ Thread cutting up to 500 mm/rev, feed per revolution up to 500 mm/rev/ Input/output resolution: 0.001 mm/ Directly programmable spindle speed/ Correction for spindle speed, feed, and rapid traverse/ Constant cutting speed with speed limitation/ 8 zero point offsets (1 general, 1 additive, 6 programmable)/ Full-circle programming with direct radius input/ Spindle positioning (resolution: 0.1 degrees)/ Tool length determination by scratching/ Data backup for 6 months via batteries/ 2 RS232C-V24 interfaces (one connected to the control panel)/ Input/output of tool data via interface/ Support for 15T machining programs/ Additional equipment: Chip conveyor, chain hinge conveyor, discharge height: 1200 mm/ Reinforced coolant pump: 40 l/min at 3 bar/ Tailstock including guideway/ Quill diameter: 90 mm/ Stroke: 90 mm (programmable)/ Quill force (adjustable): 12,000 N, MT3/ Tailstock adjustment: manual/ Tool measurement: Manually retractable measuring probe in the work area/ Manual approach to the measuring probe, transfer of tool lengths including software/ Workpiece must be unclamped for the measurement process/ Chuck: Three-jaw power chuck, Forkardt, type 3 NHF 250-65/ Spindle mount: A6, max. 4000 rpm/ With base and hard top jaws, including connecting parts

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung

Ähnliche Produkte zu Monforts RNC 4

INTEGREX 200 IV S

Mazak - Dreh-Fräszentrum

LB 3000 EX MYT

Okuma - Horizontal-Drehmaschine

PUMA 240B

DOOSAN - Horizontal-Drehmaschine

PUMA GT2100

DOOSAN - Horizontal-Drehmaschine

X-180

Takamaz - Horizontal-Drehmaschine

QTN 250M 1000L

Mazak - Horizontal-Drehmaschine

Concept Turn 105

EMCO - Horizontal-Drehmaschine

QT 35N

Mazak - Horizontal-Drehmaschine

DS-30

HAAS - Horizontal-Drehmaschine

ST-15

HAAS - Horizontal-Drehmaschine

SR20JN

Star - Swiss-Type-Drehmaschine

XW-130

Takamaz - Horizontal-Drehmaschine