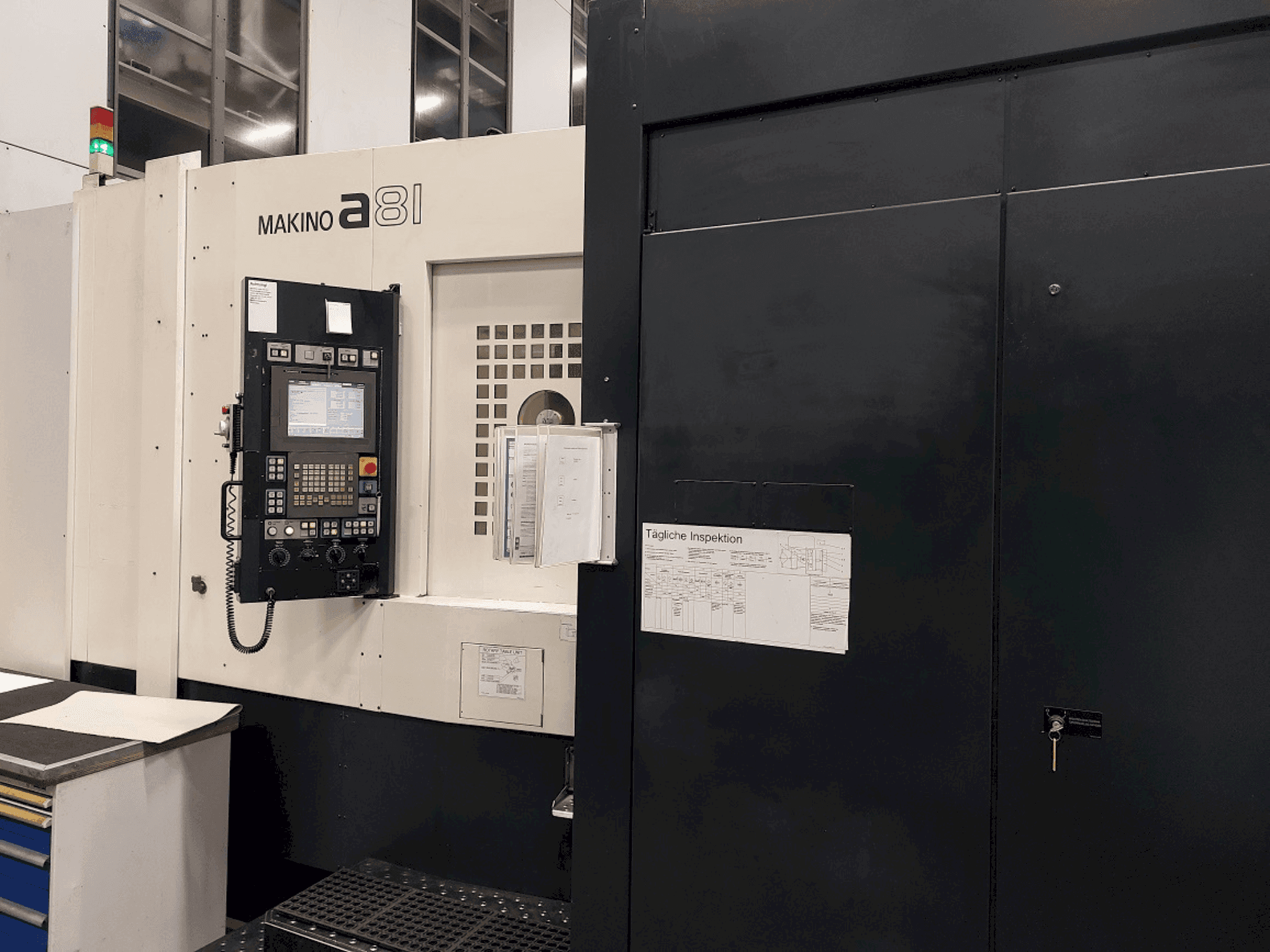

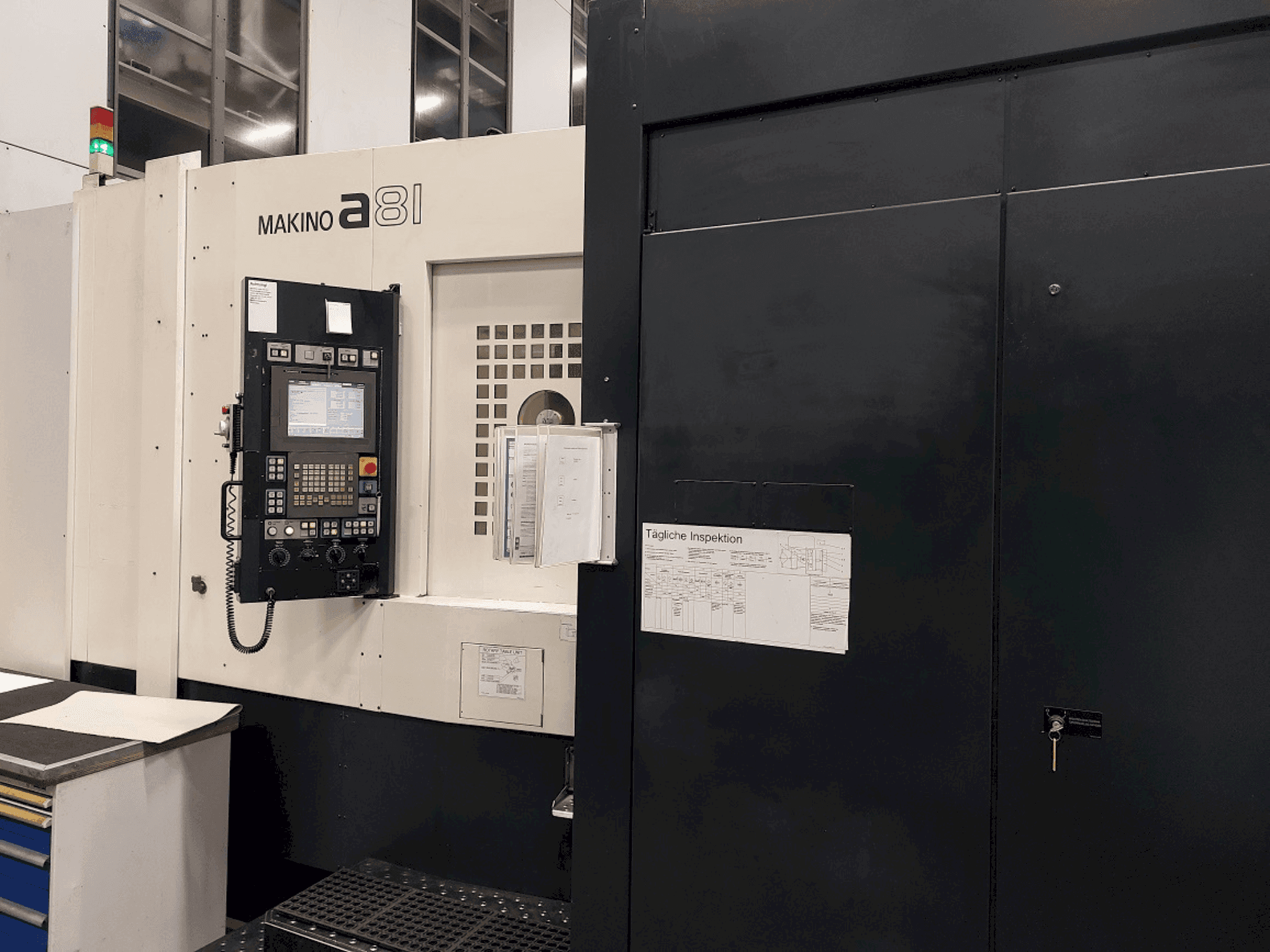

Makino - a81DE-MIL-MAK-2008-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- ➤ Used Makino a81 For Sale | gindumac.com

This 4-axis Makino a81 horizontal machining center was manufactured in 2008. It offers robust capabilities for precision machining. Consider the opportunity to buy this Makino a81 horizontal machining center. Contact us for more information.

Übersicht

- Hersteller: Makino

- jahr: 2008

- MODELL: a81

- anwendungstyp: Fräsen

- Standort: Deutschland

- maschinentyp: Horizontal-Bearbeitungszentrum

- Marke Steuergerät: MAKINO

Technische Daten - Makino a81

Steuerung

- Steuerungsmarke: MAKINO

- Steuerungsmodell: Pro5

Maße

- Tischbelastung: 1200 kg

Bewegung

- Anzahl der Achsen: 4

Technische Spezifikation

- Max. Werkzeuggewicht: 20 kg

Zusätzliche Informationen

Additional equipment

- Spindle cooling

- Tank system with Knoll compact band filter, 3200 liters

- Coolant supply through the spindle

- Oil mist extraction

- Scraper belt conveyor

- Conversion kit for stand-alone operation (currently used as a system machine)

Machine Benefits

Technical Machine Benefits

- Transverse movement (x-axis) of the column: 900 mm

- Height adjustment (y-axis) of the spindle unit: 800 mm

- Longitudinal movement (z-axis) of the table: 1020 mm

- Permissible swivel diameter in the working area: 1000 mm

- Max. Swiveling height from pallet surface: 1300 mm

- Pallet size: 630 x 630 mm

- Pallet – nc – rotary table with 4th nc axis

- Input resolution: 0. 001°

- Positioning accuracy: ± 3 arcseconds

- Tool magazine with 242 storage slots

Extra Information

Power Supply 400 V, 3-phase AC, 50 Hz Power rating: 72 kVA Control System Options for 48 zero points and Custom Macro B Tool life monitoring Tool breakage detection Adaptive feed control Compressed air through the spindle Knoll compact band filter, 3200 liters Magnetic separator Double-switching filter for IKZ Coolant supply through the spindle Compressed air through the spindle Oil mist extraction Scraper belt conveyor Control System: Makino Pro5 Options for 48 zero points and Custom Macro B Tool life monitoring Tool breakage detection (parallel to main operation) Adaptive feed control Conversion Kit for Stand-Alone Operation (Currently used as a system machine (FFS/FMS)) Pallet changer with placement of 2 pallets in alternating cycles onto a station positioned outside the working area Pallet holder rotatable, indexed at 90° intervals, 0-position electronically monitored Coding for automatic program call when inserting the pallet Pallet storage station secured with a protective device and electrical interlock

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung