Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

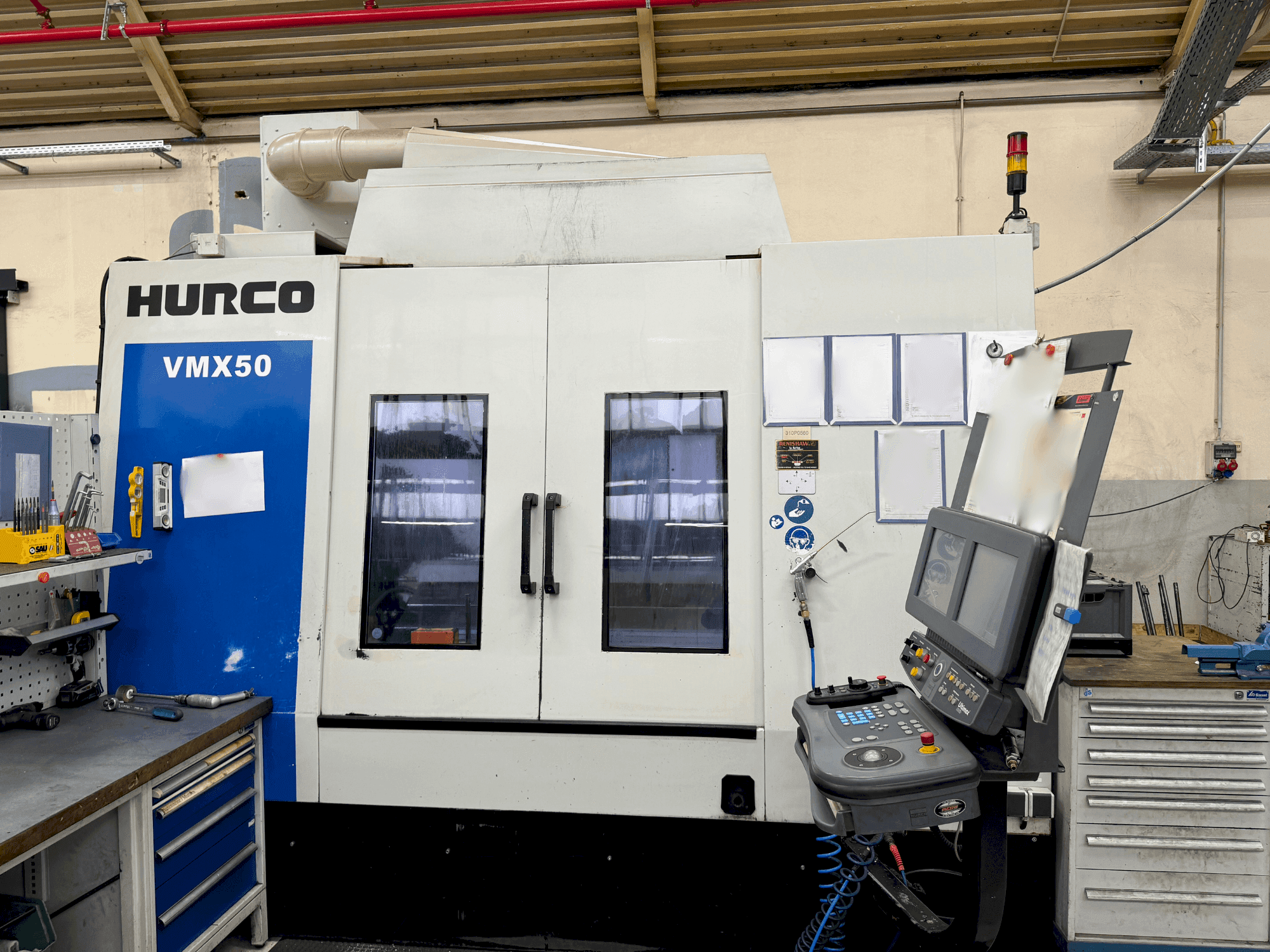

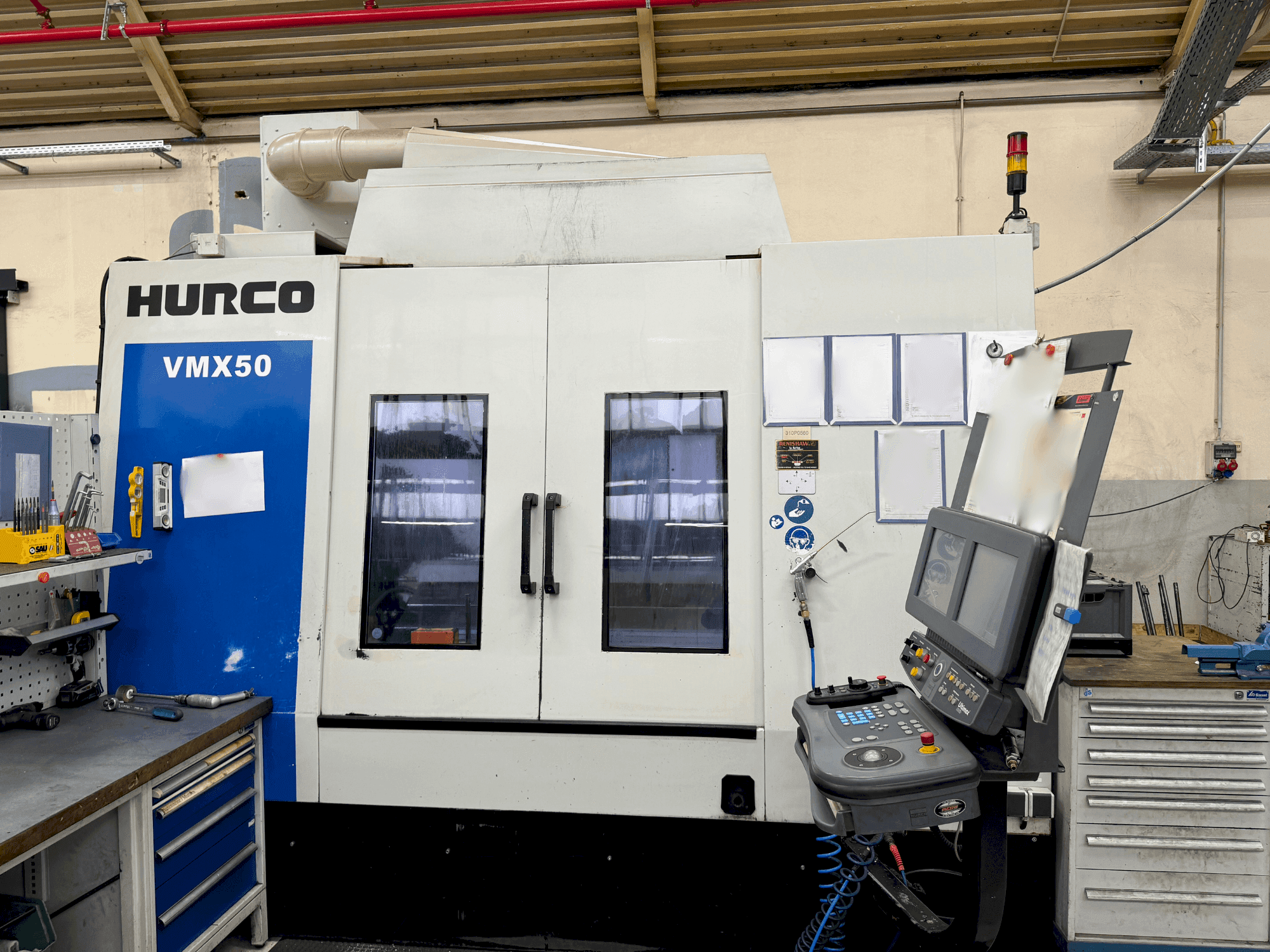

Hurco - VMX 50/40TDE-MIL-HUR-2005-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- HURCO VMX 50/40T Vertikal-Bearbeitungszentrum

Dieses HURCO VMX 50/40T Vertikal-Bearbeitungszentrum wurde im Jahr 2005 in Taiwan hergestellt. Es verfügt über eine 10.000 U/min Spindel (SK40 Werkzeugaufnahme), 3 Achsen (X = 1270 mm / Y = 660 mm / Z = 610 mm) und einen automatischen Werkzeugwechsler mit 24 Plätzen. Zum Lieferumfang gehören außerdem ein Späneförderer, ein Ölnebelabscheidesystem (ME-FI von W+W), eine Hochdruckkühlung für die Kühlmittelzufuhr durch die Spindel, ein integriertes hydraulisches Werkzeugspannsystem und die Möglichkeit der Werkstücklageerkennung und Werkzeuglängenkalibrierung mit Messtaster. Insgesamt hat die Maschine 44.358 Betriebsstunden geleistet und befindet sich immer noch in Produktion. Als zusätzliche Option kann die Maschine auf Wunsch und gegen Aufpreis mit einem KITAGAWA TT 251 Schwenk-NC-Rundtisch für 5-Achsen-Simultanbetrieb (4. Achse NC-Rotationsachse, 5. Achse Schwenken der Positionierachse in Verbindung mit der Klartext-Software & 5-Achsen-Simultan in Verbindung mit der ISO-Code-Software und entsprechendem Programmierplatz) ausgestattet werden. Kontaktieren Sie uns jederzeit für weitere Details!

Übersicht

- Hersteller: Hurco

- jahr: 2005

- MODELL: VMX 50/40T

- Produktionsstunden: 44358

- anwendungstyp: Fräsen

- Standort: Deutschland

- maschinentyp: Vertikal-Bearbeitungszentrum

- Marke Steuergerät: HURCO

Technische Daten - Hurco VMX 50/40T

Steuerung

- Steuerungshersteller: HURCO

- Steuerungsmodell: ULTIMAX 4

Maße

- Maschinengewicht: 9400 kg

Bewegung

- Anzahl der Achsen: 3

Technische Spezifikation

- Spindeldrehzahl: 10000 RPM

- Werkzeugaufnahme: SK 40

- Kühlmittelzufuhr durch die Spindel: Ja

Zusätzliche Informationen

Zusätzliche Ausrüstung

- [AUF ANFRAGE gegen Aufpreis] KITAGAWA TT 251 (4. Achse NC-Drehachse, 5. Achse Schwenken der Positionierachse in Verbindung mit der Klartext-Software)

- Späneförderer // ME-FI 1000 Ölnebelabscheider von W+W (YOM 2014)

- Kühlmittelsystem

- Späneschutzkabine

- Spülsystem zur Unterstützung der Spanabfuhr

- Kühlmittelfilterung über Pumpensaugfilter

- Signalleuchte für den Betriebszustand der Maschine

- Maschine leicht

- Satz Maschinenschuhe

- Abnehmbares elektronisches Handrad

Maschinenvorteile

Qualitative Maschinenvorteile

- Hochdruckkühlsystem zur kühlmittelzufuhr durch die spindel (kühlschmierstoff typ emulsion, kühlmitteldruck 20 bar)

- Integriertes hydraulisches werkzeugspannsystem

- Werkstücklageerkennung und werkzeuglängenkalibrierung mit messtaster

Technische Maschinenvorteile

- [auf anfrage gegen aufpreis] 4. Achse nc drehachse, 5. Achse schwenken der positionierachse in verbindung mit der klartext-software

- (auf anfrage gegen aufpreis) 5-achsen-simultan in verbindung mit der iso code software und dem entsprechenden programmierplatz (kitagawa tt 251)

- Taschenfräsen mit inseln

- Synchrones gewindeschneiden (gewindeschneiden ohne ausgleichsfutter)

- Planscheibe durchmesser 250 mm

- Spitzenhöhe 225 mm

- Spindeldurchlass 70 mm

Zusätzliche Informationen

Transportabmessungen: 3245x2250x2460 mm // Platzbedarf für den Betrieb: 4400x4750x2950 mm // Maschinenhandbuch auf CD // 2 monochrome Bildschirme (Text + Grafik) // 2 Softwareeinheiten (1 x Klartext-Dialogprogrammierung an der Maschine + 1 x für ISO-Code-Programmierung durch externes Programmiergerät oder CAD/CAM-System über RS-232 C- oder V 24-Schnittstelle) Pentium-Technologie, 1,6 GB Festplatte, 64 MB RAM, parallele und serielle Datenschnittstellen, DOS-kompatibles 3,5"-Laufwerk 1,44 MB // Systeminterne Selbstdiagnose, DOS-Verzeichnisstruktur, Softwareversion 2.xx

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung