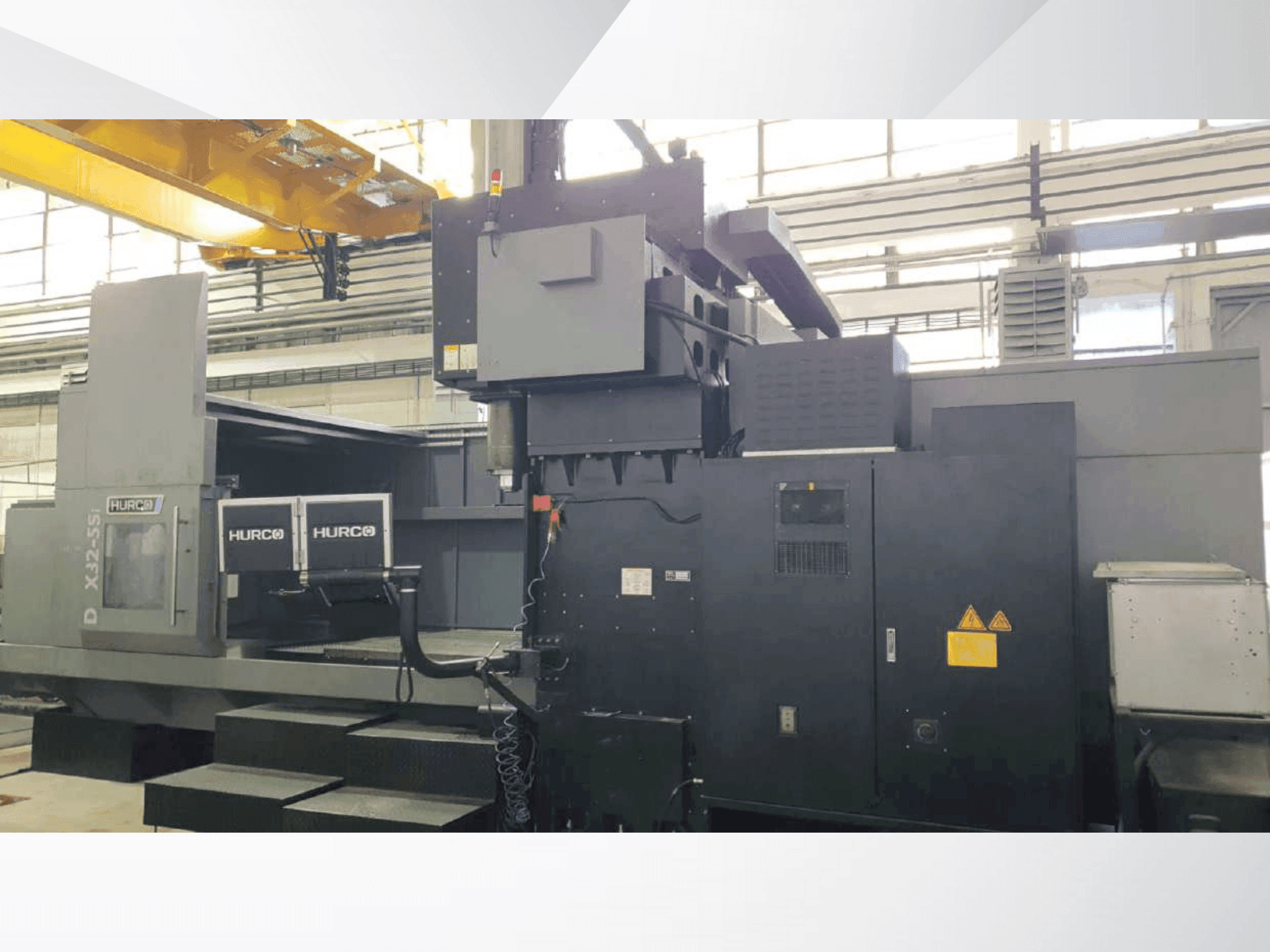

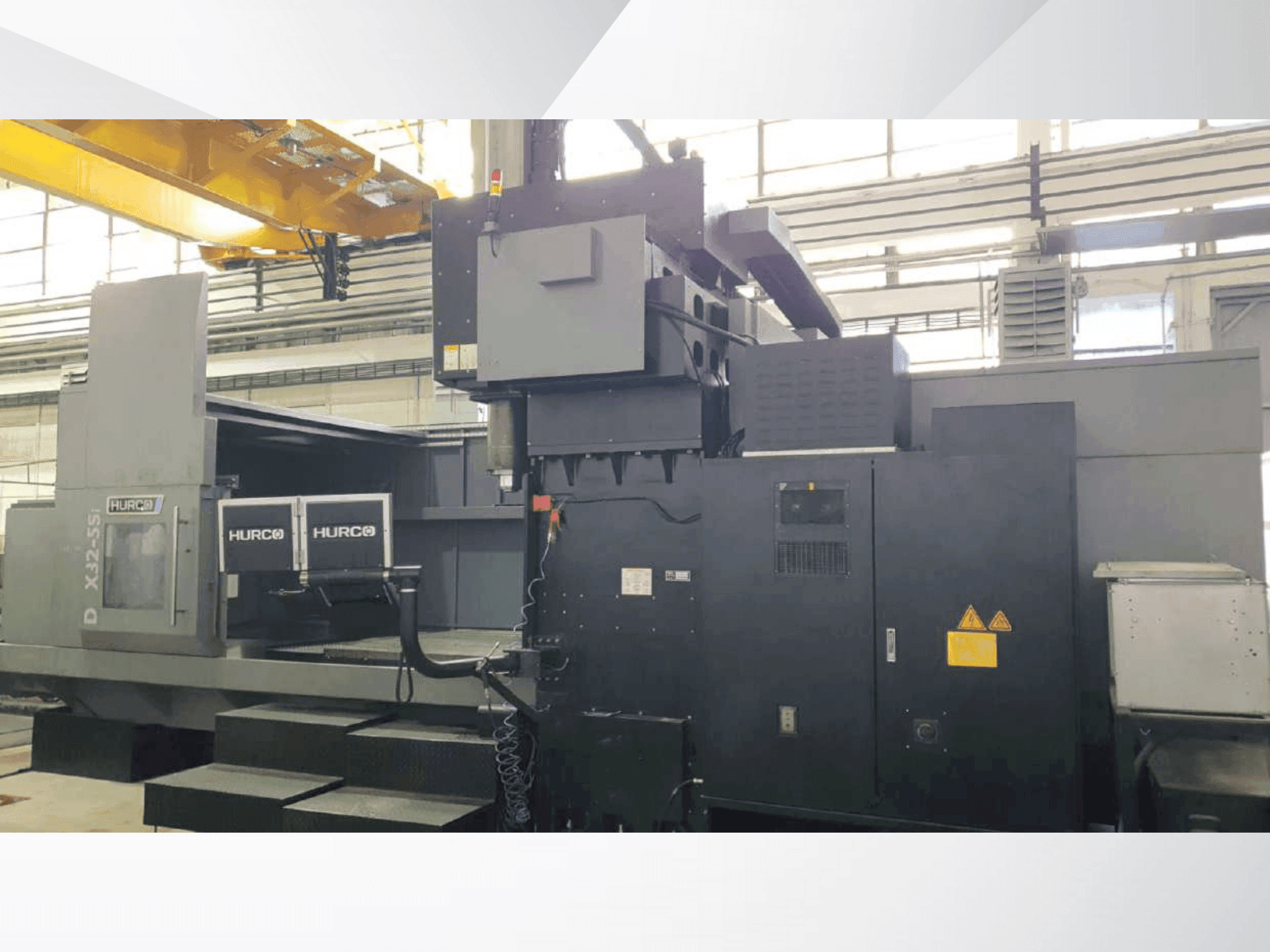

Hurco - DCX32-5SiRO-MIL-HUR-2016-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- ➤ Used Hurco DCX32-5Si For Sale | gindumac.com

This 3-axis Hurco DCX32-5Si vertical machining centre was manufactured in 2016. It features a large work surface of 3,000x1,700 mm, supports a maximum table load of 11,000 kg, and offers extensive travel distances with X at 3,200 mm, Y at 2,100 mm, and Z at 920 mm. Equipped with a high-speed main spindle capable of 18,000 rpm and a robust 40-position tool magazine, this machine is ideal for complex, large-scale machining tasks. Contact us for more information about this machine.

Übersicht

- Hersteller: Hurco

- jahr: 2016

- MODELL: DCX32-5Si

- Produktionsstunden: 27000

- anwendungstyp: Fräsen

- Standort: Rumänien

- maschinentyp: Vertikal-Bearbeitungszentrum

- Marke Steuergerät: HURCO

Technische Daten - Hurco DCX32-5Si

Steuerung

- Steuerungsmarke: HURCO

- Steuerungsmodell: WinMax 5

Maße

- Maschinentiefe: 9960 mm

- Maschinenhöhe: 4724 mm

- Maschinengewicht: 35000 kg

- Tischlänge: 3000 mm

- Tischbelastung: 11000 kg

- Tischbreite: 1700 mm

Bewegung

- X-Achsverfahrweg: 3200 mm

- Y-Achsverfahrweg: 2100 mm

- Z-Achsverfahrweg: 920 mm

Technische Spezifikation

- Max. Werkzeuggewicht: 15 kg

- Anzahl der Werkzeuge: 40

- Spindelleistung: 35 kW

- Spindeldrehzahl: 18000 RPM

Zusätzliche Informationen

Additional equipment

- Oversized linear guides and ultra-rigid roller linear guides

- Ball screws with double nut and automatic centralized lubrication system

- Screw chip conveyor and chip conveyor with scrapers

- Machine interior washing system with emulsion gun/compressed air

- Ring with emulsion nozzles in the shaft head

- Large side doors for access

- LED-illuminated workspace

- Heat exchanger in the electrical cabinet

- Premium remote control equipped with LCD display

- IKZ-20 Spindle cooling CTS20 (20 bar)

Machine Benefits

Qualitative Machine Benefits

- Wired remote control

- Advanced graphic verification with 3d part model simulation

- Conversational pocket and island programming

- Ac main spindle motor with double coil

- Main shaft cooling system

- Automatic tool change

- Laser tool length measurement (renishaw nc4)

- Synchronized rigid threading without special tool

- Part measurement with probe, radio connection (renishaw rmp 40)

- Linear scales for x, y, and z axes

Technical Machine Benefits

- Work advances: 10 m/min

- X/y/z positioning accuracy: 0. 025 mm

- Repeatability: 0. 015 mm

- T-channels: 7x22x220 mm

- Atc tool change time (dry): 5 sec

- Advanced graphic verification and simulation features

- Extensive material and tool library

- Enhanced control and measurement systems

- Robust construction and maintenance features

Extra Information

Machine still under power

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung