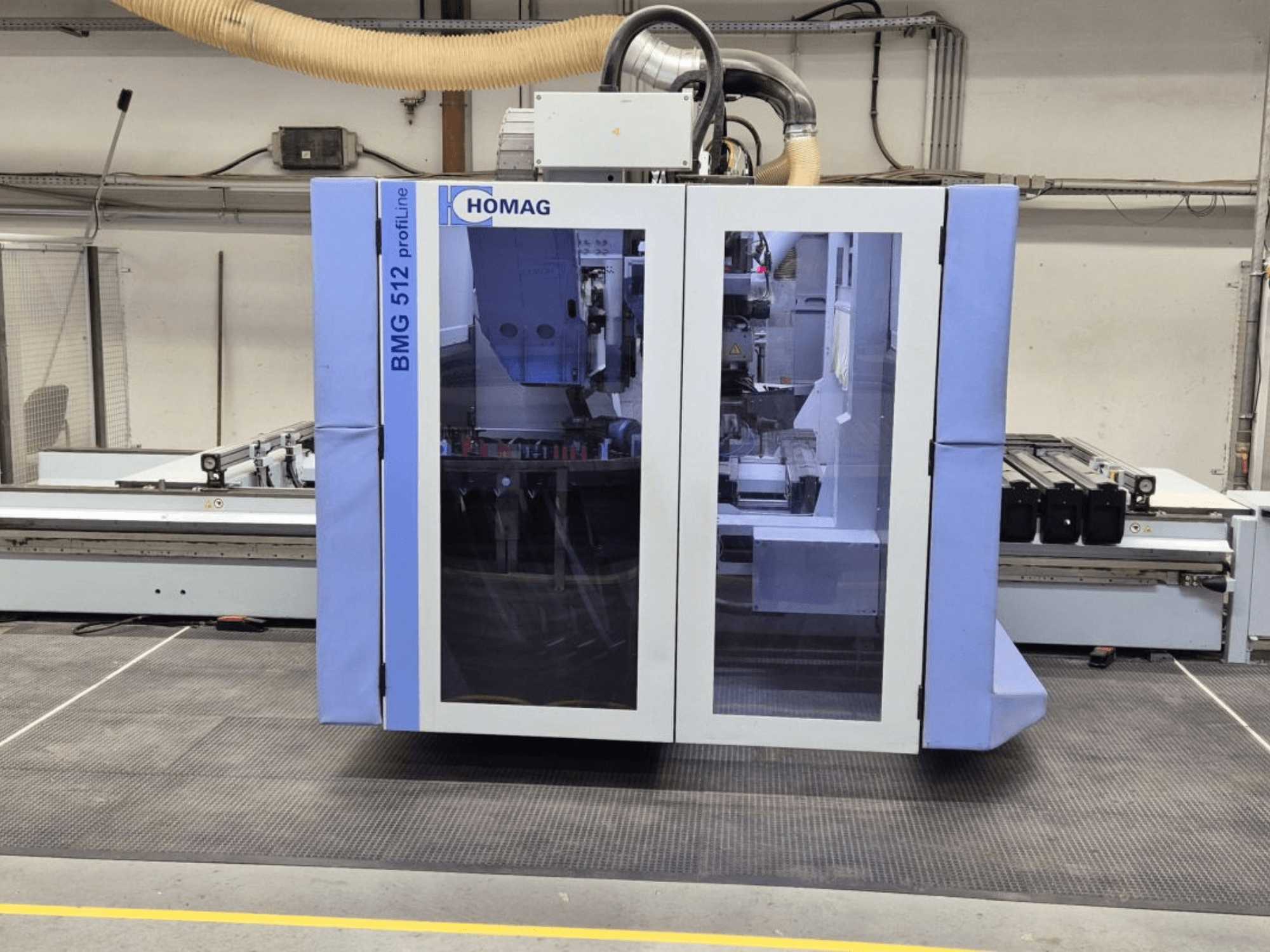

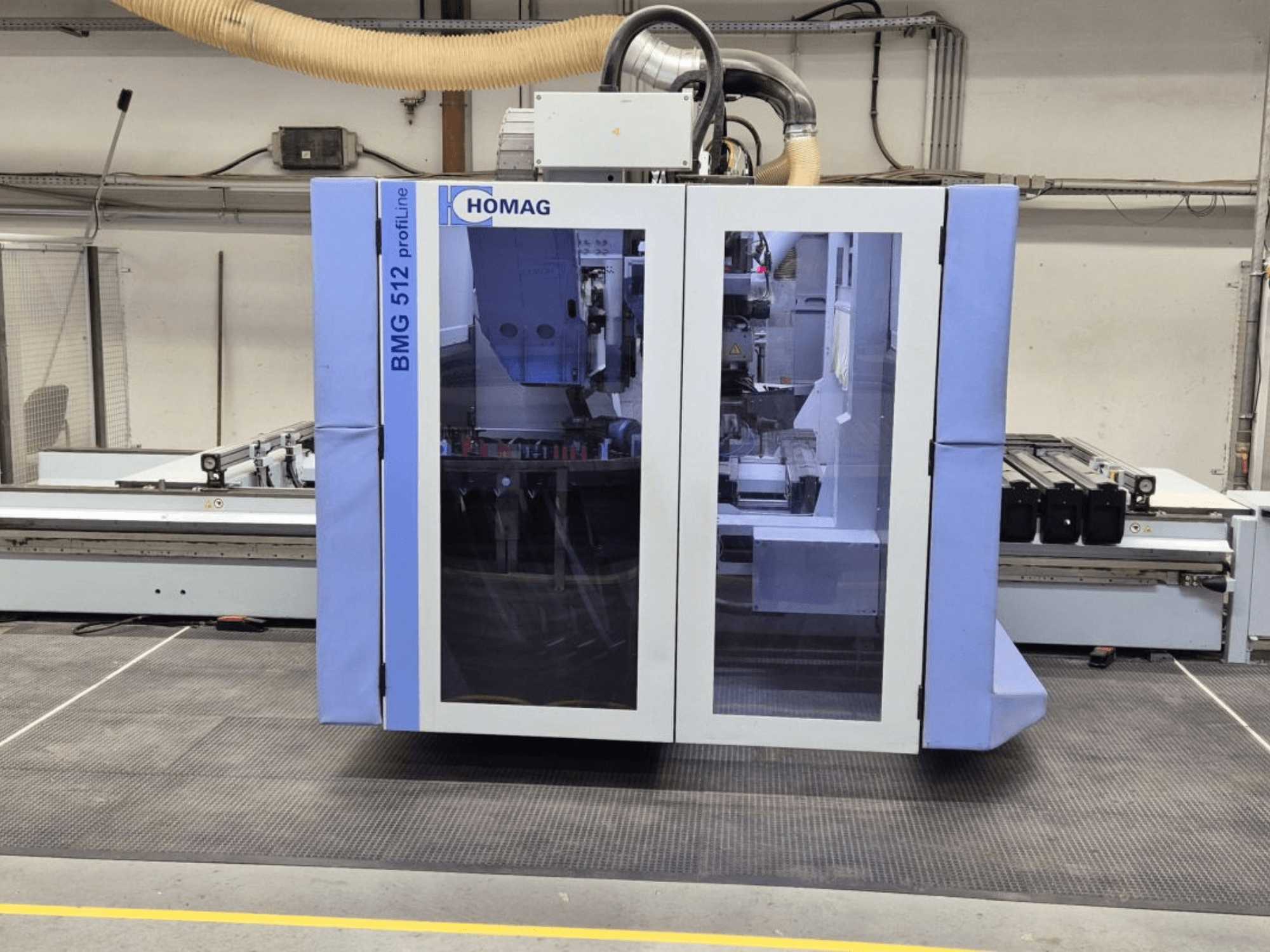

HOMAG - PROFI BMG 512/40/12/V/ADE-CNC-HOM-2016-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Holzbearbeitung

- ➤ Gebrauchte HOMAG PROFI BMG 512/40/12/V/A | Bearbeitungszentrum

Diese 4-achsige HOMAG PROFI BMG 512/40/12/V/A wurde 2016 hergestellt und ist mit einem POWEREDGE Verleimteil und einem 4-fach Kantenmagazin ausgestattet. Sie verfügt über einen 18-fach-Scheibenwerkzeugwechsler, eine 12-kW-Bearbeitungsspindel und eine C-Achse mit unbegrenztem Schwenkbereich. Die Maschine unterstützt Werkstücklängen bis zu 4000 mm und Werkstückdicken bis zu 300 mm. Sie ist ideal für die moderne Holzbearbeitung und bietet eine dynamische Raumaufteilung für eine optimale Ausnutzung des Bearbeitungsbereichs. Kontaktieren Sie uns für weitere Informationen zu dieser Maschine.

Übersicht

- Hersteller: HOMAG

- jahr: 2016

- MODELL: PROFI BMG 512/40/12/V/A

- anwendungstyp: CNC-Bearbeitung

- Standort: Deutschland

- maschinentyp: CNC-Bearbeitungszentrum

Zusätzliche Informationen

Zusätzliche Informationen

Werkstück

Längen: 4000 mm für Einzelaufstellung / 2250 mm für Pendelaufstellung

Breiten: 1450 mm für alle Einheiten und Frontanschlag

Maximale Werkstückdicke: 300 mm (einschließlich Spannvorrichtungen)

Bis zu 60 mm mit Standard-Spannvorrichtungen ohne Einschränkungen für Geräte und Absaugung.

Tisch

Automatischer Konsolentisch

Automatisch verstellbarer Konsolentisch

8 Konsolen Y = 1500 mm

16 Seiten- und Anschlagstifte 140 mm, elektromechanisch gesteuert

Dynamische Raumaufteilung für optimale Ausnutzung im Pendelbetrieb

Verschiedene Doppel-Vakuumspanner

Ohne Vakuumpumpe; Versorgung über ein bauseitiges Vakuumsystem

Werkzeuge

18-fach Scheibenwerkzeugwechsler

Hauptantrieb

Bearbeitungsspindel: 12 kW (S6-Betrieb) / 9,5 kW (S1-Betrieb)

Spindel mit Hybridlagern

Frequenzgesteuerte Rotation: 0 - 24000 U/min

Automatische Vorschubreduzierung bei abnehmender Spindeldrehzahl

Einspritzeinheit

POWEREDGE Verleimaggregat

Verleimaggregat für 360°-Kantenverleimung an Stumpfstößen

Leimauftrag über Auftragswalze auf Kantenmaterial

1 Andruckrolle Ø 50 mm, 1 Nachlaufrolle Ø 35 mm

Max. Kantenhöhe: 65 mm

Kantenstärke: 0,4 - 3 mm (Furnier 0,4 - 2 mm / PVC 1,0 - 2 mm)

Heißluftdüse zur Erwärmung von Dickkanten auf kleinen Radien, steuerbar über NC

Maschinensteuerung

POWERCONTROL PC 86 POWERTOUCH

Mit 21,5" Full-HD Multitouch-Display

WoodWOP zur grafischen, dialogorientierten Erstellung von CNC-Programmen

Diagnosesystem WOODSCOUT

Zusätzliche Ausstattung

Schnittstelle für FLEX 5-Aggregat

C-Achse mit Aggregateschnittstelle

Unbegrenzter Schwenkbereich

Kupplungselement für automatischen Werkzeugwechsel der FLEX 5-Einheit

Bohrkopf

21 Spindeln V17 / H4 / S0 / 90°

17 vertikale Bohrspindeln mit Schnellwechselsystem

T-förmige Anordnung: 7 Spindeln in Y-Richtung / 11 Spindeln in X-Richtung

4 Horizontalspindeln mit Säge 0 / 90°

Vorschneidestation

Verfährt mit dem Bearbeitungsportal (X-Achse)

Säge / Fräsaggregat für Werkzeugwechsler

Kombiniertes Beschneide- und Eckenrundungsaggregat, sensorgesteuert

Kombiniertes Bündigfräsaggregat / Ziehmesseraggregat

Zusätzliche Informationen

Kühlmittelbehälter für Bearbeitungsspindel

Integrierter Späneförderer, nach links abführend

Hinweis: Die technischen Daten und Beschreibungen dienen nur zur Information und sind nicht verbindlich.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung