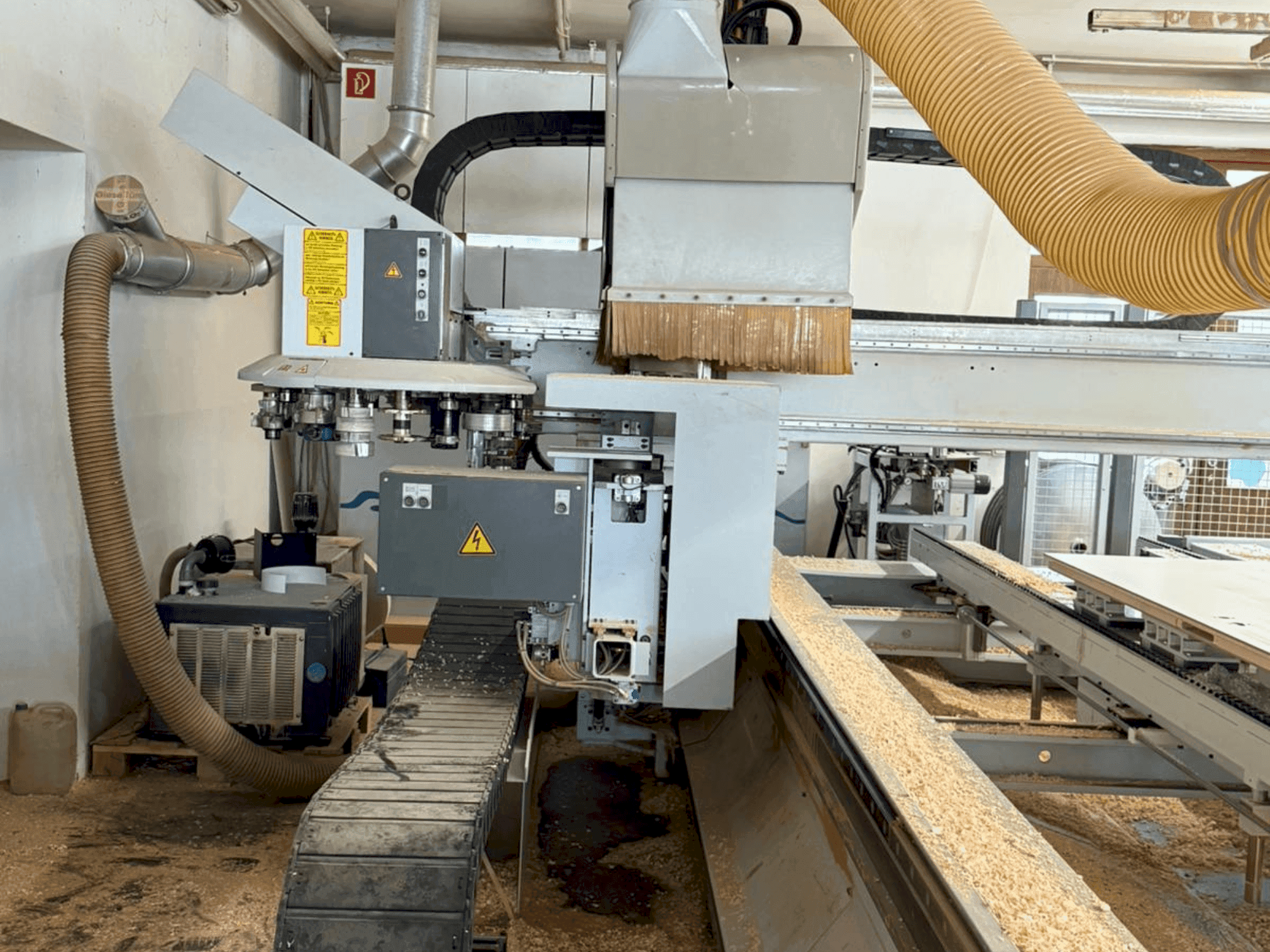

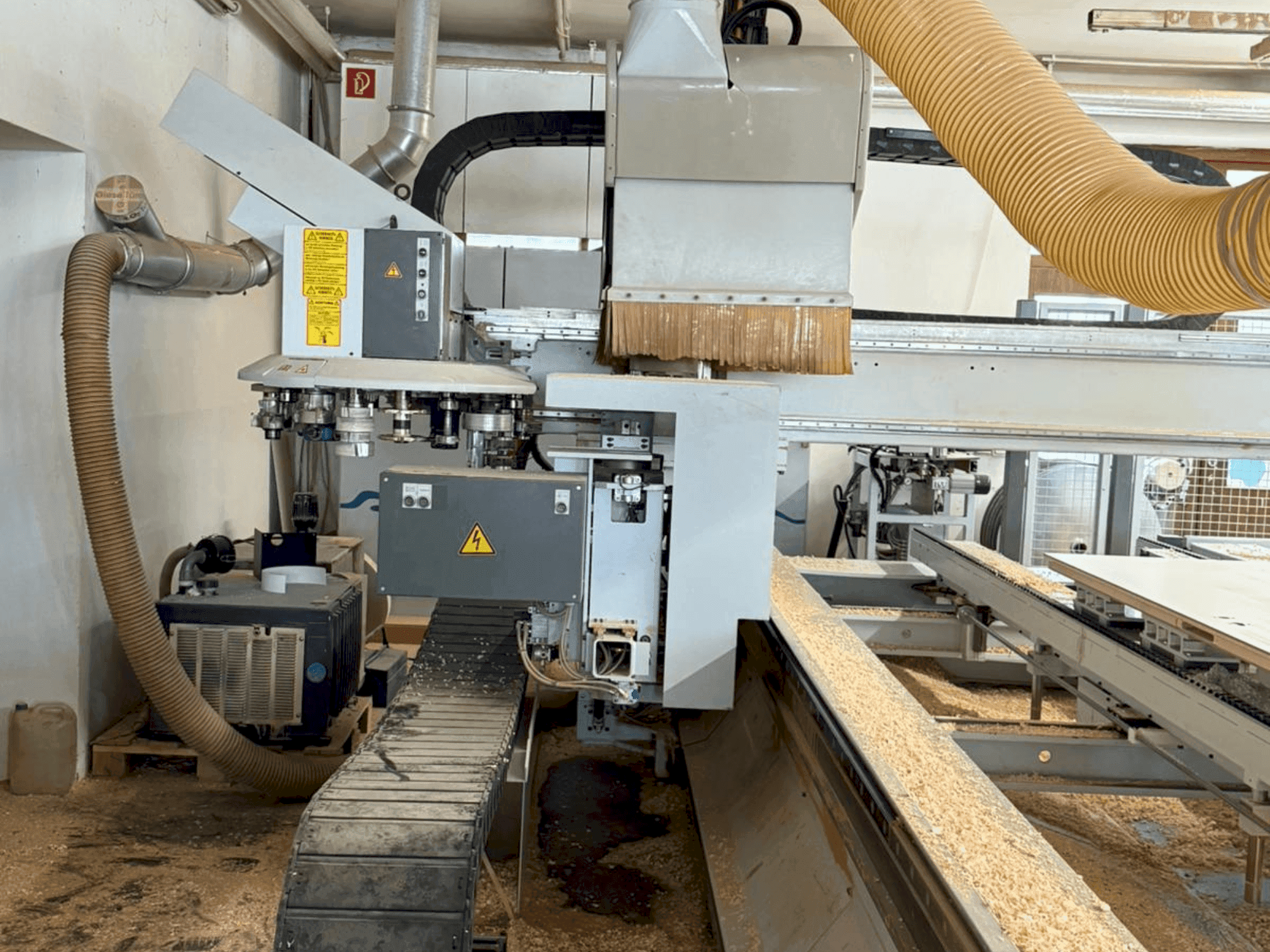

HOMAG - PROFI BAZ20/30/16/V/DDE-CNC-HOM-2003-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Holzbearbeitung

- ➤ Used HOMAG PROFI BAZ20/30/16/V/D For Sale | gindumac.com

This 4-axis HOMAG PROFI BAZ20/30/16/V/D was manufactured in 2003. It features a Homatic CNC control, WOODWOP CNC programming, an 18-position disk changer, and a main spindle with a 12 kW three-phase motor. Capable of handling workpieces up to 3000 mm in length and 1400 mm in width, it includes a continuous table with adjustable vacuum clamps. Consider the opportunity to buy this HOMAG PROFI BAZ20/30/16/V/D CNC Wood Machining Centre. Contact us for more information.

Übersicht

- Hersteller: HOMAG

- jahr: 2003

- MODELL: PROFI BAZ20/30/16/V/D

- anwendungstyp: CNC-Bearbeitung

- Standort: Deutschland

- maschinentyp: CNC-Holzbearbeitungszentrum

- Verfügbar ab: 01/09/2026

Technische Daten - HOMAG PROFI BAZ20/30/16/V/D

Bewegung

- Anzahl der Achsen: 4

Technische Spezifikation

- Spindeldrehzahl: 18000 RPM

Zusätzliche Informationen

Control/Software: Homatic CNC control; WOODWOP CNC programming system; Postprocessor

Workpiece capacity:

Length 800–3000 mm; Width 350–1400 mm; Thickness max. 70 mm with edge / 80 mm milling

Frieze width min. 120 mm; Weight max. 150 kg

Table/Clamping:

Continuous table (D-table)

Longitudinal console 1 fixed; Longitudinal console 2 manual Y-width adjustment

8 vacuum clamps 125 x 50 x 100 mm

Working height lower edge of workpiece 950 mm

Unit for moving vacuum clamps on unit carrier with pneumatic extension console (max. 4 clamps per longitudinal console)

Width adjustment (longitudinal console/D-table): Servo drive, per longitudinal console

Stop bolt for top layer overhang: Lifting/rotating device, max. 20 mm top layer, stroke 110 mm, individually selectable, end-position monitored (for manual door placement)

Main spindle:

Speed 1500–18000 rpm (VFD 15 kW), full rated power from 12000 rpm

Tool diameter max. 180 mm (milling) / 200 mm (grinding); Room extraction for all tools/units

Aggregate interface/C-axis:

Pneumatic and swivel drive interface

C-axis with torque drive and 3-point support

Tool changer:

18-position disk changer for HSK F63; tool weight 6 kg; tool length max. 200 mm

Configurations: 18 x Ø max. 130 mm; or 9 x Ø max. 180 mm + 9 x Ø max. 70 mm; grinding tools Ø max. 200 mm

Changer raisable for traveling pickup (left side)

Units/aggregates (for tool changer unless noted):

Drilling/milling unit, 4 spindles: ER25 up to Ø16 mm shank, protrusion max. 50 mm, speed max. 13500 rpm, unlimited swivel via C-axis

Lock case milling unit, 2 spindles D=16/20: counter-rotating, 12000 rpm, integrated blow-out, unlimited swivel via C-axis

Swiveling saw/drill unit: manual 0–90°, flange Ø30 mm, TK Ø52 mm, prepared for crosscut saw Ø max. 180 mm, drill chuck with Weldon D=10 mm, speed max. 9000 rpm, C-axis swivel

Milling cutter holder D=30 with chip guide: mandrel length 45/80 mm, chip guide plate controlled via C-axis, changer space Ø 140 mm

Flush milling unit: simultaneous top/bottom, edge radius max. R12 mm, min. outer radius ~R5 mm / inner radius ~R30 mm at 90°, scanning top/bottom/side, unlimited C-axis swivel, speed max. 12000 rpm, workpiece thickness max. 50 mm, min. overhang ~35 mm, with narrow feeler shoes

WPL knife head: run-out angle 5°, Ø 70 mm

Gluing/edgebanding equipment:

Drive spindle/V for gluing units: mounted right side of boom; cross slide with Y anti-reb and Z extension stroke; anti-reb spindle with C-axis and electrical/electronic interface; dedicated Z-axis

Gluing unit 4 sides, 90 mm (for main spindle): straight edges with direct glue application; 1 pre-press roller + 1 pneumatic post-press roller (programmable); inner radius min. R40 at 90°; edge height max. 90 mm; veneer thickness 0.4–1 mm; folding pressure zone on main spindle with hot-melt reactivation

Edge hold-down device, manual adjustment

Magazine/pickup:

Pickup space on X-support for interchangeable special unit (e.g., motor-driven swiveling machining spindle)

Connectivity: Ethernet network connection

Additional equipment

Chip conveyor belt: Integrated chip/scrap disposal via chip belt below longitudinal crossbars

Vacuum pump: 100/140 m³/h

External pre-chopping station with 3-stage roller, automatic:

Roller turntable on operator side; roller Ø 800 mm

Edge length min. 350 mm; edge height max. 90 mm

Residual edge length monitoring with feed stop at 2400 mm

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung

Ähnliche Produkte zu HOMAG PROFI BAZ20/30/16/V/D

BIMA 310 120/300

IMA - CNC-Holzbearbeitungszentrum

KM-95 G1

KRÜSI - CNC-Holzbearbeitungszentrum

BIMA CUT 120/300

IMA - CNC-Bearbeitungszentrum

ProTec 571

GANNOMAT - CNC-Holzbearbeitungszentrum

BIMA CUT 120/240

IMA - CNC-Holzbearbeitungszentrum

Mastercraft 2137

OMAKSAN - CNC-Holzbearbeitungszentrum

ELECNC 2200x3700

BLUE ELEPHANT - CNC-Fräse

MD TOP XLS CA2

COMEC - CNC-Holzbearbeitungszentrum

Speed-Cut SC1

HUNDEGGER - CNC-Holzbearbeitungszentrum

PROFI BMG 512/40/12/V/A

HOMAG - CNC-Bearbeitungszentrum

BIMA CUT 145/330

IMA - CNC-Holzbearbeitungszentrum

MD TOP XL

COMEC - CNC-Holzbearbeitungszentrum