Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

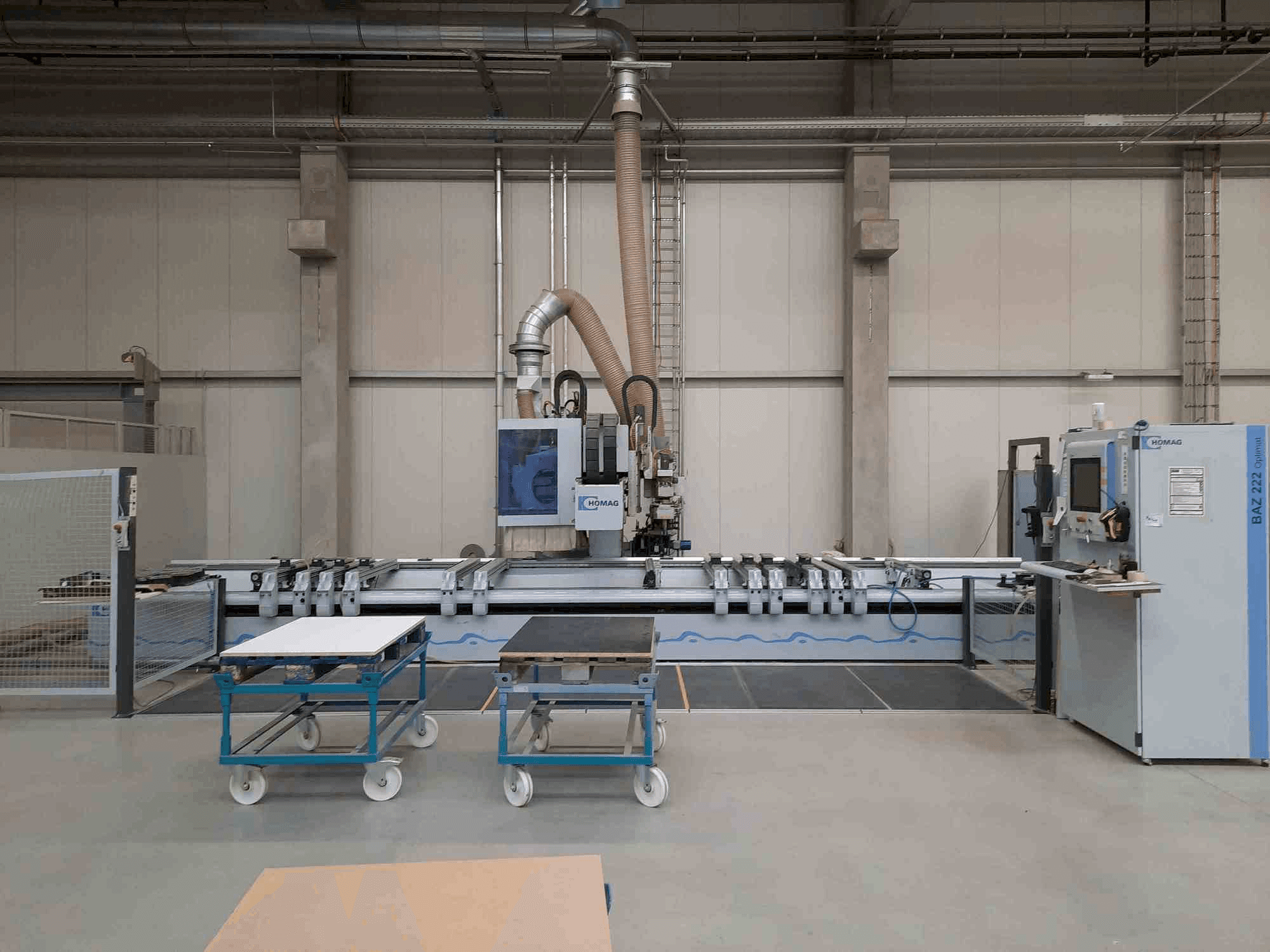

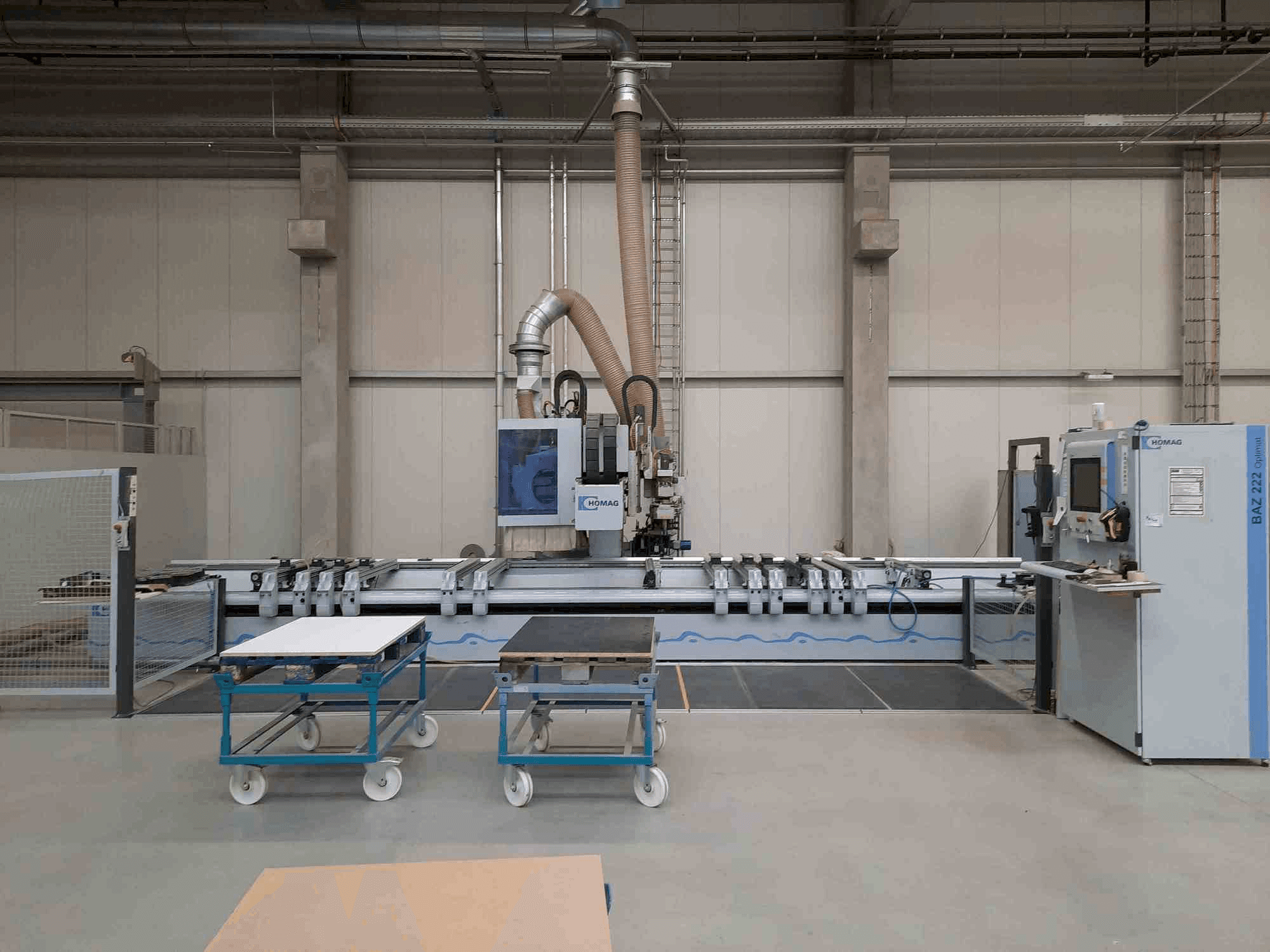

HOMAG - OPTIMAT BAZ222/60/KDE-WOO-HOM-2010-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Holzbearbeitung

- ➤ Gebrauchte HOMAG OPTIMAT BAZ222/60/K - Zu verkaufen

Dieses CNC-Bearbeitungszentrum wurde im Jahr 2010 hergestellt. Es verfügt über eine Hauptspindel von 15 KW mit HSK F63, einen 18-fachen Plattenwechsler und einen 30-spindligen Bohrkopf. Ausgestattet mit einem POWER EDGE Anleimaggregat für präzises Kantenanleimen und einem FLEX-5-Aggregat für mehr Vielseitigkeit. Ideal für die Bearbeitung großer Werkstücke mit einer maximalen Dicke von 300 mm. Für weitere Informationen über dieses Holzbearbeitungszentrum nehmen Sie bitte Kontakt mit uns auf.

Übersicht

- Hersteller: HOMAG

- jahr: 2010

- MODELL: OPTIMAT BAZ222/60/K

- anwendungstyp: CNC-Bearbeitung

- Standort: Deutschland

- maschinentyp: CNC-Bearbeitungszentrum

Zusätzliche Informationen

Zusätzliche Ausrüstung

- Verleimungseinheit mit FLEX-5 Einheit

- Hauptspindel 15 KW, HSK F63

- C-Achse mit Geräteschnittstelle

- Tellerwechsler 18-fach D=130

- Bohrkopf 30 Spindeln: V20 / H10/ S360° "MPU"

- Nutsäge: Blatt-Ø: 200 mm

- Adaptive Frässpindel 6 KW für Bohrkopf

- Verleimteil POWER EDGE für 360°-Verleimung mit Stumpfstoß

- Bündigfräseinheit für Werkzeugwechsler

Maschinenvorteile

Qualitative Maschinenvorteile

- Präzision bei der bearbeitung mit fortschrittlicher cnc-steuerung, die hochwertige oberflächen gewährleistet

- Flexibilität bei der handhabung verschiedener werkstückgrößen und komplexer bearbeitungen mit dem flex-5-aggregat und dem elektrischen kantenanleimsystem

Technische Maschinenvorteile

- Kombi-bündigfräsen-schabegerät bd 100 mm

- Kombi-endbeschnitt- und kopiergerät, durchleuchtet

- Schlitzfräseinheit 2 spindeln d=16/20

- Spänetransportband für b200/52-72

- Led-aufstellkonsole 1300-1600 mm

- Vielseitige bearbeitungsmöglichkeiten wie fräsen, bohren, verleimen und kantenanleimen

- Hochleistungs-hauptspindel und adaptive frässpindel erhöhen die bearbeitungseffizienz

- Umfassende werkzeugoptionen mit einem 18-fachen plattenwechsler und spezialeinheiten für besondere aufgaben

Zusätzliche Informationen

Werkstückabmessungen:Länge max: Alle Geräte: Einzelfeld 6.000mm, Pendelverfahren 2.375mm. Breite max: Frontal alle Aggregate 1150mm, beim Fräsen mit Werkzeug-Diam. 25 mm: 1220mm, bei Kantenanleimen: 1220mm. Dicke max: 300 mm (inkl. Spannfutter bei Einsatz als Oberfräse), bis max. 60 mm bei Standardaufspannung. Kantenmaterialhandling mit einer Höhe von 105 mm für das Anleimaggregat BAZ222/322, ermöglicht das Kanten von Werkstücken bis zu 100 mm Dicke.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung