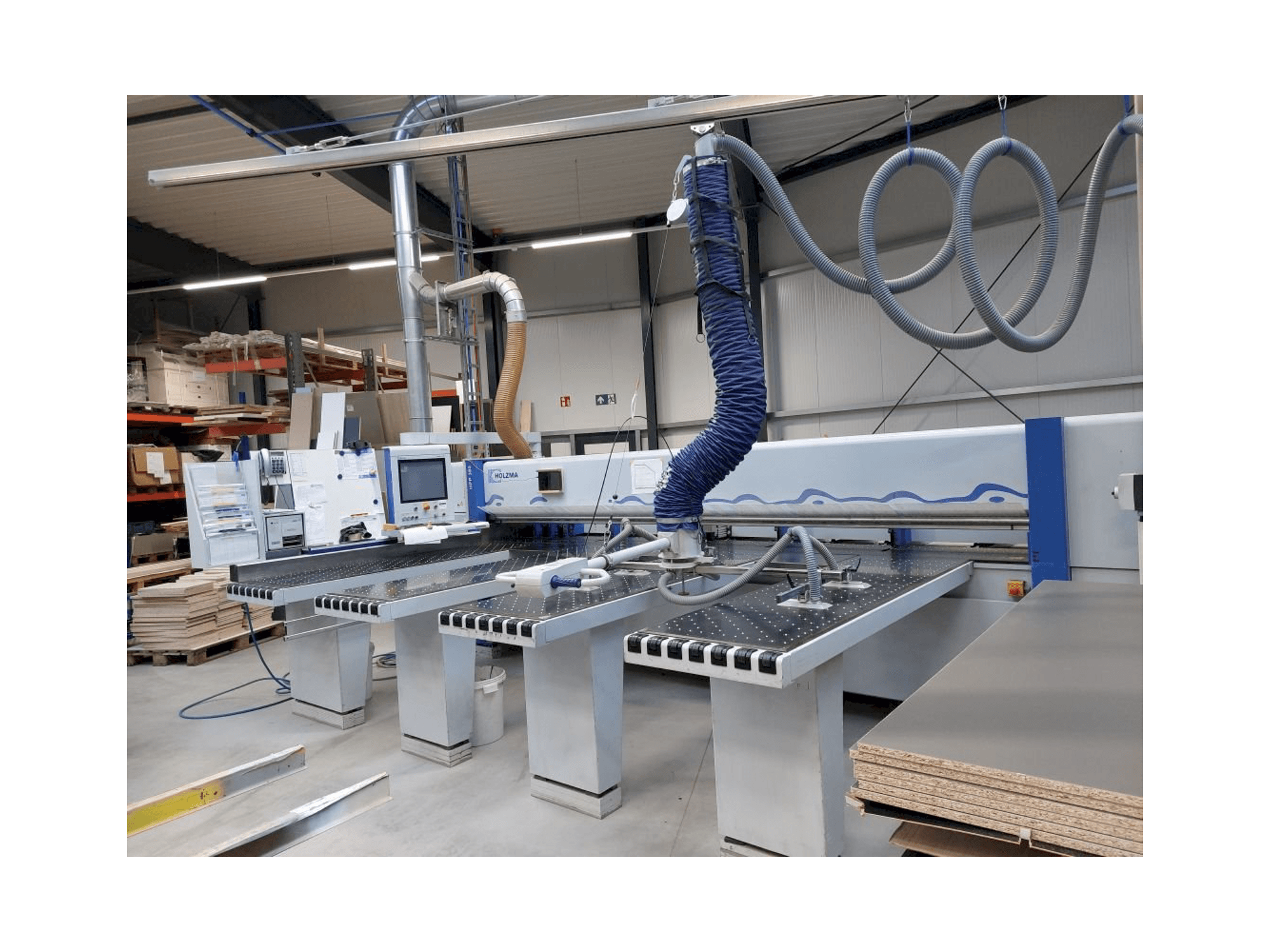

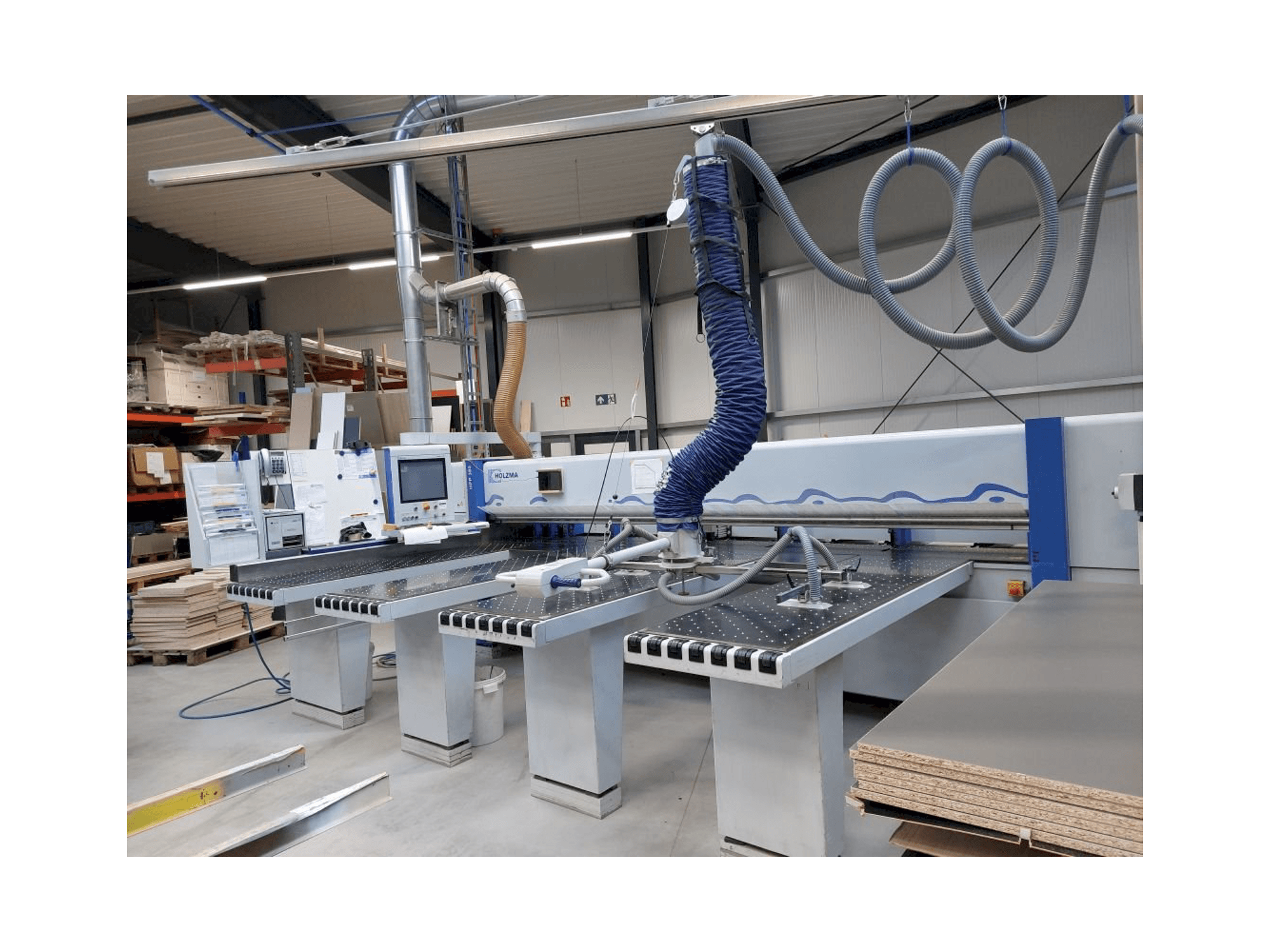

HOLZMA - HPP 380DE-SAW-HOL-2007-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Holzbearbeitung

- ➤ Gebrauchte HOLZMA HPP 380 - 2007 - Säge zu verkaufen | gindumac.com

Diese HOLZMA HPP 380 Plattensäge wurde im Jahr 2007 hergestellt. Sie verfügt über einen robusten Stahlsägewagen, Haupt- und Vorschnittsägen und eine patentierte zentrale Winkelrückführung, die die Zykluszeit um bis zu 25 % reduziert. Die Maschine ist mit einem Power Control CADmatic 4 System ausgestattet, das einen präzisen und effizienten Betrieb gewährleistet. Der Sägeblattüberstand beträgt 95 mm, und sie arbeitet mit einem Hauptsägemotor von 18,0 kW. Für weitere Informationen über diese Plattensäge nehmen Sie bitte Kontakt mit uns auf.

Übersicht

- Hersteller: HOLZMA

- jahr: 2007

- MODELL: HPP 380

- anwendungstyp: Sägen

- Standort: Deutschland

- maschinentyp: Plattensäge

Technische Daten - HOLZMA HPP 380

Steuerung

- Steuerungsmodell: CADmatic 4 - Professional

Zusätzliche Informationen

Zusätzliche Ausrüstung

- Luftkissentisch mit Rollenelement 2160 x 650 mm: 4 Stück

- Zentrales Gebläse: 1 Stück

Maschinenvorteile

Qualitative Maschinenvorteile

- Ce-zertifiziert, gs-zertifiziert, fph-holzstaub zertifiziert

- Teilung: 75/275/475/1050/1850/2650/3450 mm gemessen vom winkelmaß bis zur mitte der spannzange

- 2 zusätzliche zwei-finger-spannzangen möglich

- 4 manuelle besäumungsrechen an spannzangen

- 1 zusätzliche ein-finger-spannzange möglich

- Düsenabstand der luftkissentische: 70 x 70 mm

Technische Maschinenvorteile

- Motor der zuschnittsäge: 2. 2 kw

- Betriebsspannung: 400 v / 50 hz

- Elektrischer anschlusswert am hs-motor: 18. 0 kw = 24 kw, 21. 0 kw = 27 kw

- Genauigkeit der positionierung: +/- 0. 1 mm/m

- Oberflächenschonender materialtransport, lebenslange positioniergenauigkeit, keine schmierung erforderlich, hohe programmschiebergeschwindigkeit, wartungsfrei, volle stabilität des stahltisches bleibt erhalten, einfacher, kostengünstiger austausch der phenolharzplatten, minimaler verschleiß der zylinder, gleichmäßige druckbeaufschlagung, minimaler schnitt = kratzschnitt, deutliche taktzeitersparnis, höchste schnittqualität, minimale rüstzeiten, reduzierung der taktzeit, druckstärke elektrisch einstellbar

- Schnittlänge: 4300 mm

- Schnittbreite (programmschieberweg): 4250 mm

- Rollenbahn (element 10-spurig): 1 stück

- Rollenbahn (element 2-spurig): 5 stück

- Spannzangen: 7 stück (die ersten 3 stück zweifingrig, alle anderen einfingrig)

Zusätzliche Informationen

Maschine noch unter Strom

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung