Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

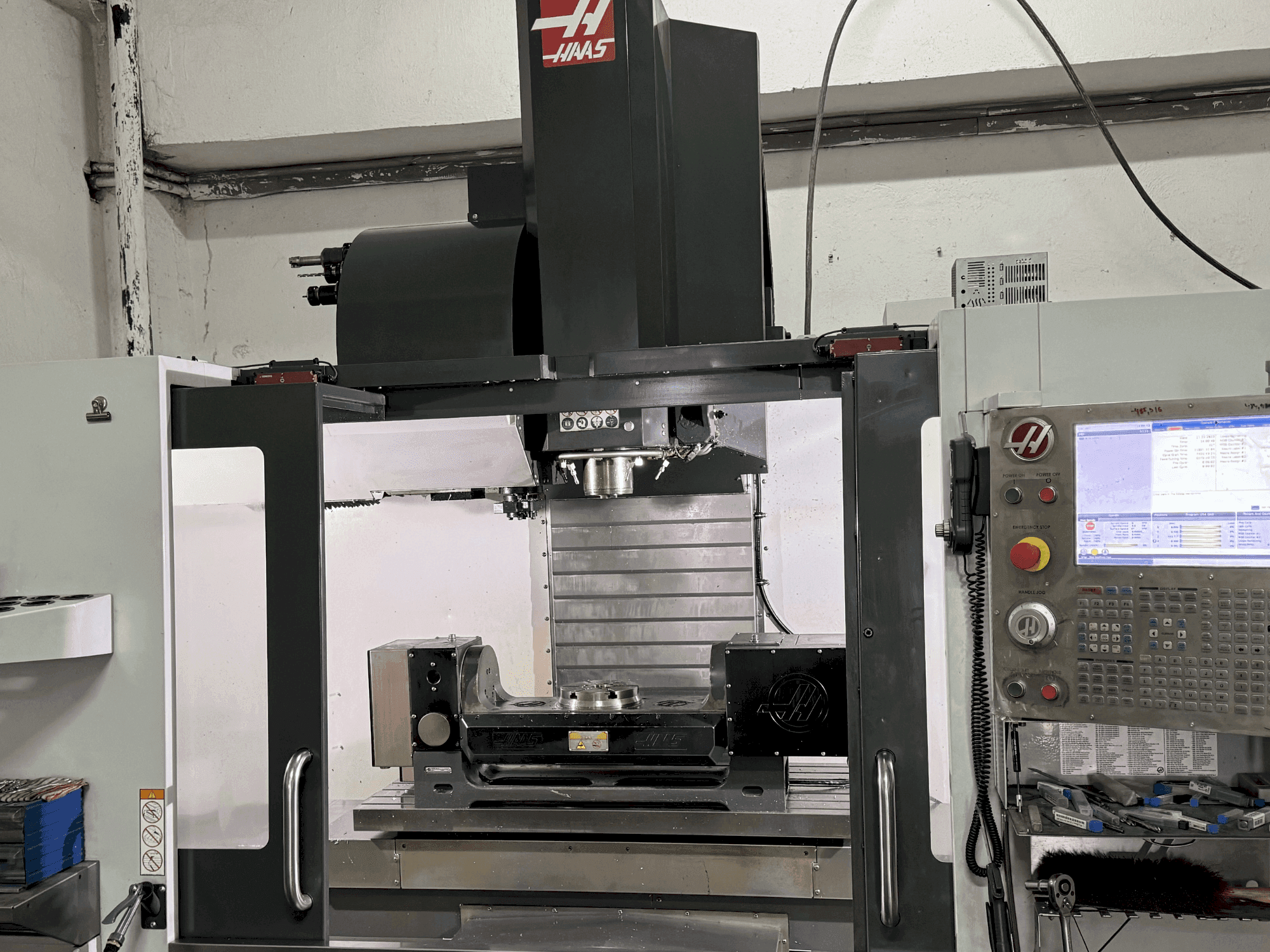

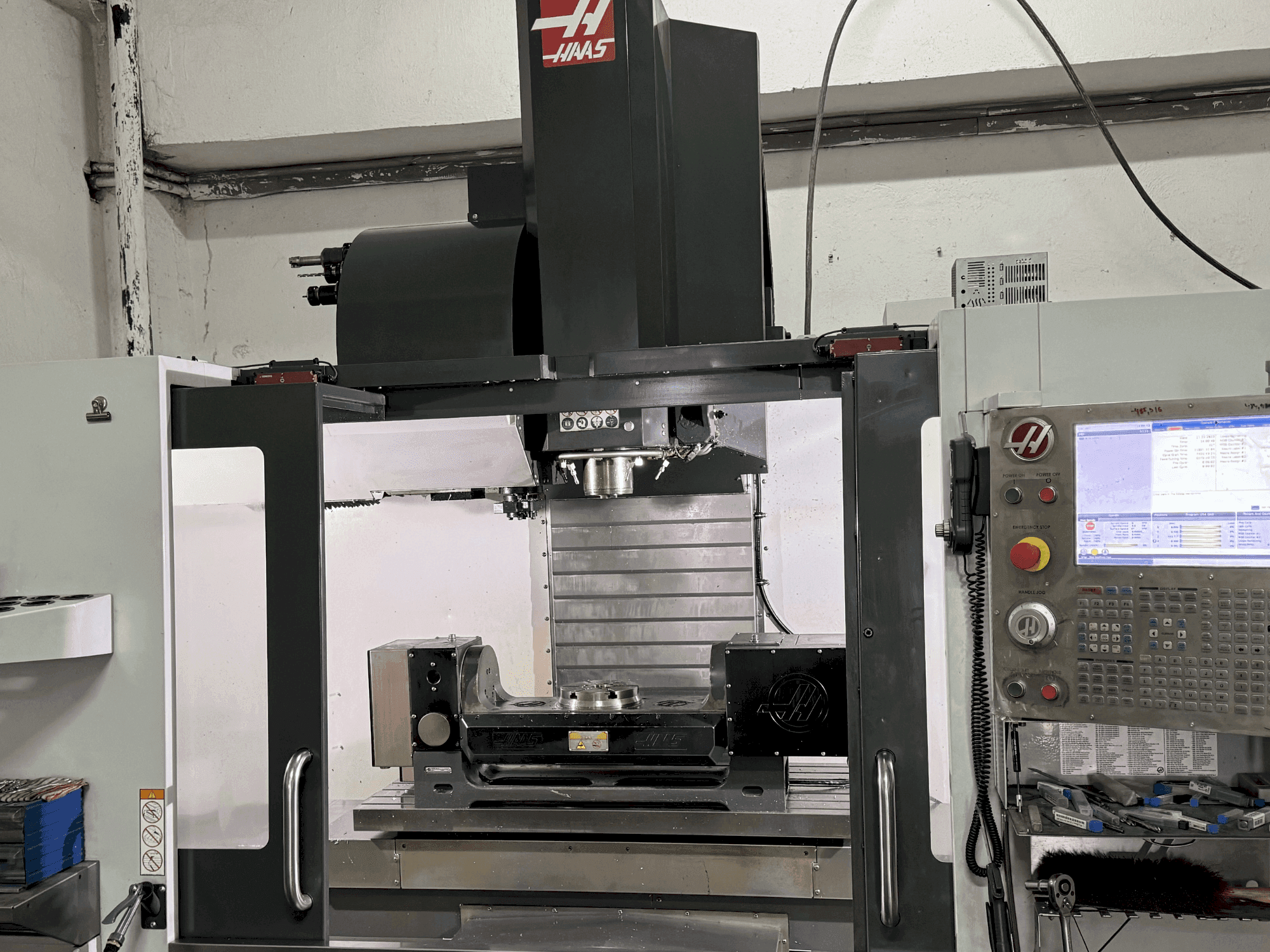

HAAS - VF-5/40TRBG-MIL-HAA-2018-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- HAAS VF-5/40TR Vertical Machining center

This HAAS VF-5/40TR Vertical Machining center was manufactured in the year 2018 in the United States. It is equipped with a HAAS control unit and has 5 axis (removable 210 mm 2-axis thumb rotary table). The machine has a programmable Coolant Nozzle; a multi-position nozzle that automatically directs coolant precisely at the cutting tool. It has a spindle speed of 8100 rpm.

Übersicht

- Hersteller: HAAS

- jahr: 2018

- MODELL: VF-5/40TR

- anwendungstyp: Fräsen

- Standort: Bulgarien

- maschinentyp: Vertikal-Bearbeitungszentrum

- Marke Steuergerät: HAAS

Technische Daten - HAAS VF-5/40TR

Steuerung

- Steuerungsmarke: HAAS

Bewegung

- Anzahl der Achsen: 5

Technische Spezifikation

- Spindeldrehzahl: 8100 RPM

Zusätzliche Informationen

Additional equipment

- 95 gallon (360 liter) flood cooling system

- 24 +1 side-bayonet tool changer

Machine Benefits

Qualitative Machine Benefits

- Media display is used within an nc program to call up media files (images, videos, pdf files) from memory and display them on the control screen as the program runs.

- High-speed machining; allows faster feedrates and more complex toolpaths, without hesitation or starving the machine.

- Remote jog handle with extra-large touchscreen display; lets you to get up-close to the machine’s work area for part setup, changeover, and inspection, while still having control of the machine.

- Rigid tapping; synchronized tapping, with built-in tap cycles.

- Through-spindle coolant, 300 psi (21 bar). Provides high-pressure coolant directly through the cutting tool. Requires 3-phase power. Note: tsc cannot be installed in the field unless the tsc-ready option is ordered with the machine.

- Through-tool air blast; supplies high-pressure / high-flow air through the tool, directly to the cutting edge. Available for inline spindles, and 50-taper mills. Requires a haas through-spindle coolant system, or the tsc ready option.

- Auxiliary coolant filter system; a bag-style filtration system that keeps the coolant free of particulates down to 25 microns. Note: if high-pressure flood coolant (high pressure cool) is installed, do not connect the auxiliary coolant filter (acf) directly to the high-pressure flood coolant pump. To use the auxiliary coolant filter with high-pressure flood coolant, the filter must be connected through an optional through-spindle coolant (tsc) system.

- Programmable coolant nozzle; a multi-position nozzle that automatically directs coolant precisely at the cutting tool.

- Dwo/tcpc

- Machine other options: acf/tab /tsc/wips-r/rtap-3

Technical Machine Benefits

- 5-axis vertical machining center (1270 x 660 x 635 mm) with removable 210 mm, 2-axis thumb rotary table

- X-axis: 1. 270mm / y-axis: 660mm / z-axis: 635mm / a-axis: +-120° / b-axis: 360°

- 40 cones

- 30 hp (22. 4 kw) vector disc // 710 ipm (18. 0 m/min) rapids

- Built-in direct drive vane

- Wireless intuitive probing system: renishaw. Includes the haas visual programming system, macros, spindle orientation, and coordinate rotation and scaling.

- Standard program memory: 1 gb of onboard memory for program storage and backup.

- Chip auger: automatically removes chips from the machine, while compressing them and wringing out the coolant.

- Haasconnect: remote monitoring of your haas machine. Requires the machine to be connected to the internet.

- Ethernet interface: allows you to easily transfer files to and from the machine over a local wired network.

Extra Information

USB port, key lock memory, hard tapping, 15" LCD screen, 750 MB program memory, coordinate rotation and scaling, color distantion push handle, macros, high speed milling, automatic chip auger, programmable coolant nozzle

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung