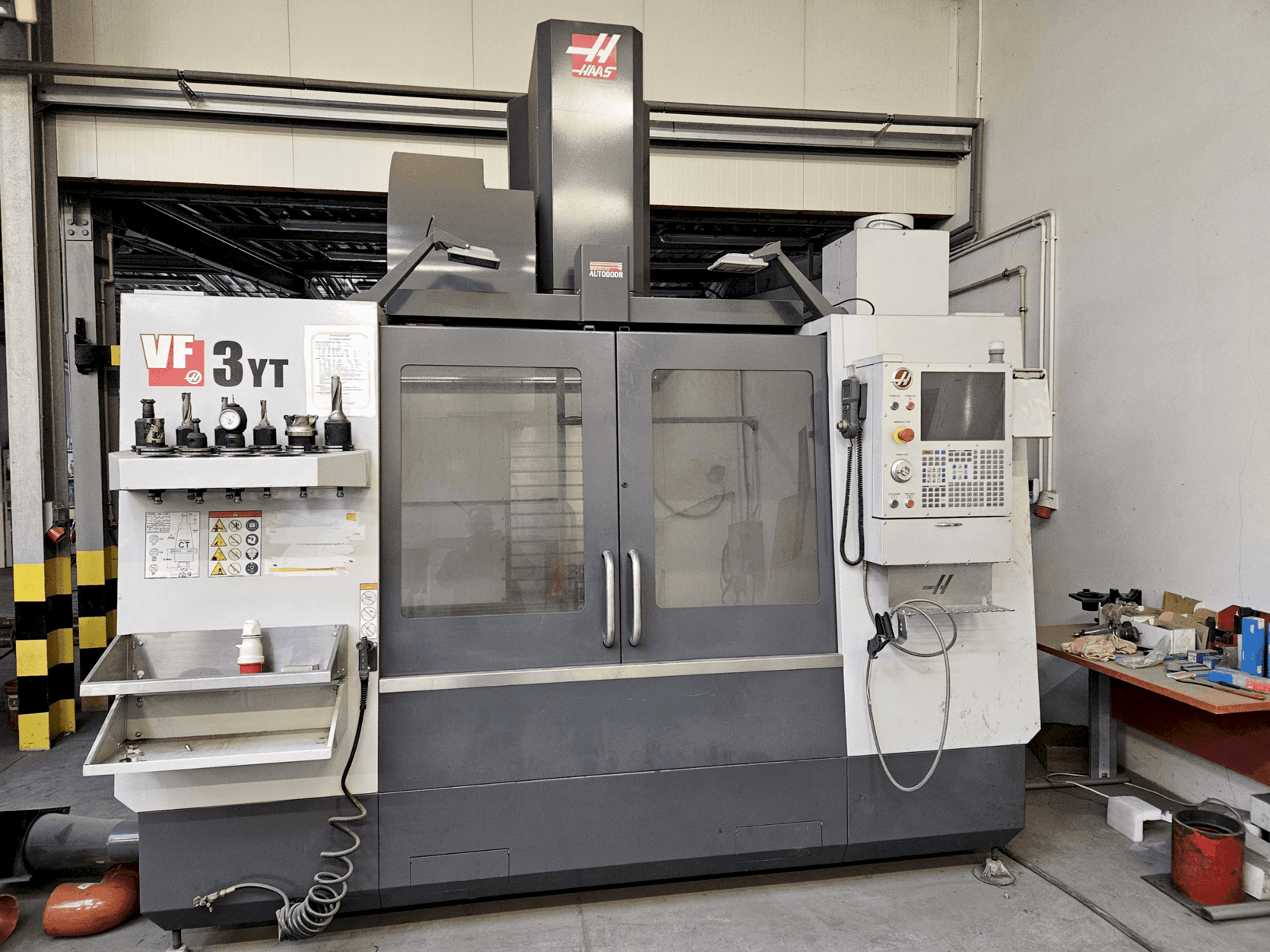

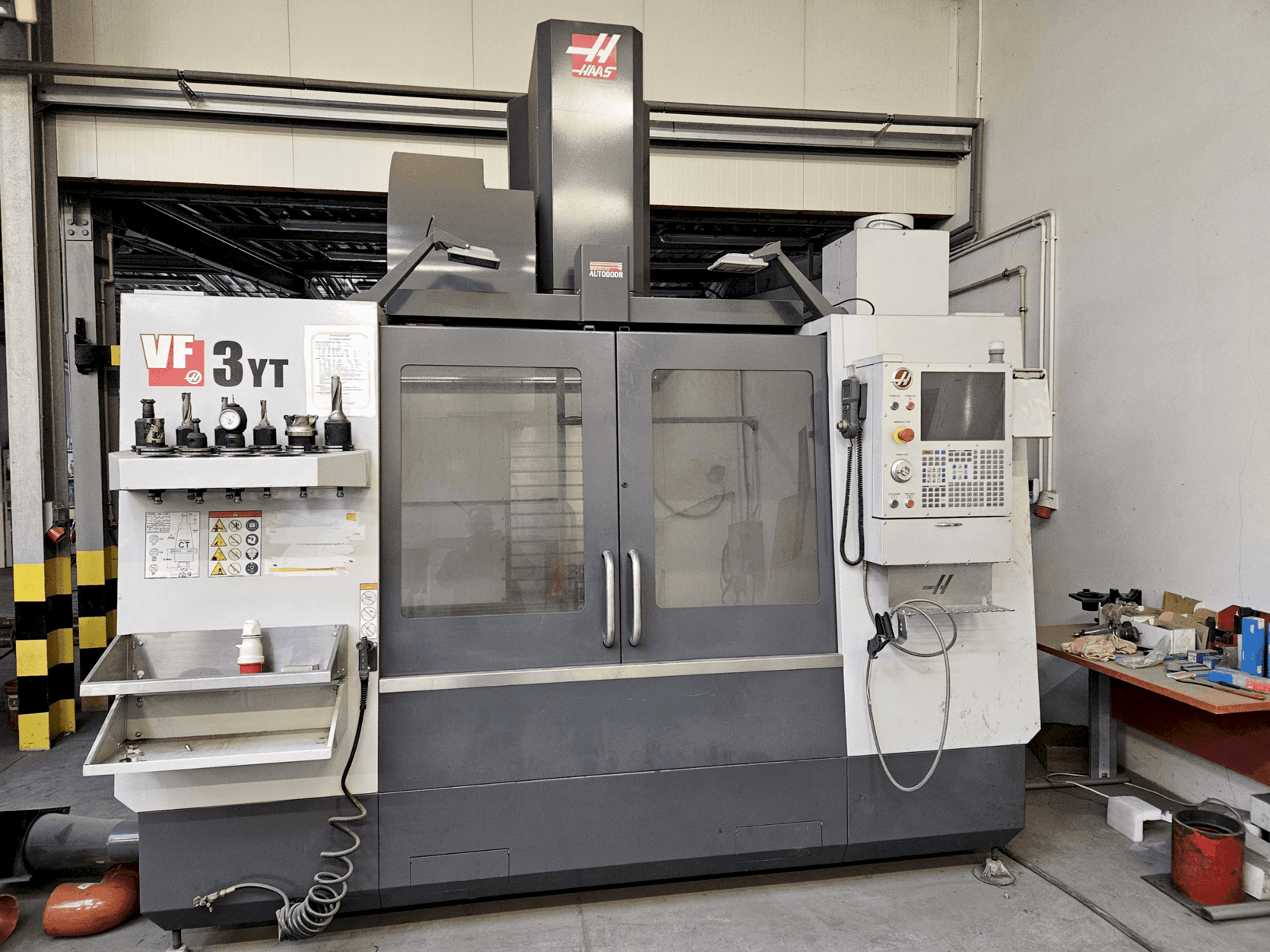

HAAS - VF-3YT/50PL-MIL-HAA-2017-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- HAAS VF-3YT/50 Vertikal-Bearbeitungszentrum

Dieses HAAS VF-3YT/50 Vertikal-Bearbeitungszentrum wurde im Jahr 2017 in den Vereinigten Staaten hergestellt und hat 238 Produktionsstunden. Es ist mit einer HAAS-Steuerung ausgestattet und hat 3 Achsen. Die Maschine hat eine Spindeldrehzahl von 12000 U/min.

Übersicht

- Hersteller: HAAS

- jahr: 2017

- MODELL: VF-3YT/50

- Produktionsstunden: 238

- anwendungstyp: Fräsen

- Standort: Polen

- maschinentyp: Vertikal-Bearbeitungszentrum

- Marke Steuergerät: HAAS

Technische Daten - HAAS VF-3YT/50

Steuerung

- Steuerungshersteller: HAAS

Maße

- Maschinengewicht: 7212 kg

- Tischlänge: 1372 mm

- Tischbreite: 610 mm

Bewegung

- Anzahl der Achsen: 3

- X-Achsen-Verfahrweg: 1016 mm

- Y-Achsen-Verfahrweg: 660 mm

- Z-Achsen-Verfahrweg: 635 mm

Technische Spezifikation

- Anzahl der Werkzeuge: 30

- Spindeldrehzahl: 7500 RPM

Zusätzliche Informationen

Maschinenvorteile

Qualitative Maschinenvorteile

- Schneckenspäneförderer

- Spindelkegel luftblasen

- Gewindeschneiden ohne ausgleichsfutter

- Installation für druckluftanschluss

- Modul zur frühzeitigen erkennung von stromausfällen

- Programmierbare winkelposition der kühlmitteldüse

- Handsender mit lcd-display /schalthebel/

- Kühlsystem mit ausziehbarem kühlmittelbehälter

- Automatische zentralschmieranlage

- Wips-r kabelloses messtastersystem zum messen von werkzeugen in radius und länge, zum messen und einstellen von teilen mit messzyklen. Beinhaltet so, macro, coord, und vps (visual programming system)

Technische Maschinenvorteile

- Kühlung durch die spindel

- Spindelkegel iso50, typ ct

- Speicherkapazität 1 gb, netzwerkkarte

- Haasconnect - fernüberwachung des betriebszustands von maschinen

- 15" lcd-monitor und usb-anschluss

- Elektronisches handrad

- Kühlsystem für die spindel

- Temperaturkompensation für gewindespindeln

- Schutzkabine mit schiebetüren vorne und seitenfenstern, die sich aufklappen lassen

- Magazin mit 30 positionen

Zusätzliche Informationen

-CT Spindelkonus, Typ CT -ACF Zusätzliches 25 μm-Filtersystem, unerlässlich für die Bearbeitung von Gusseisen, Aluminium, Holz, Kunststoffen auf Phenolharzbasis und anderen staubbildenden Materialien -TSC* Spindeldurchgangskühlung, Hochdruckpumpe /21 bar, 22 l/min/ (ACF-Option erforderlich) -HIL Zusätzliche Halogen-Kammerbeleuchtung -ENCL EXHAUST Ölnebelabsaugung. Kann an ein Lüftungsnetz angeschlossen werden -WIFI Drahtloses Netzwerk -TAB Blasluft durch die Spindel.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung