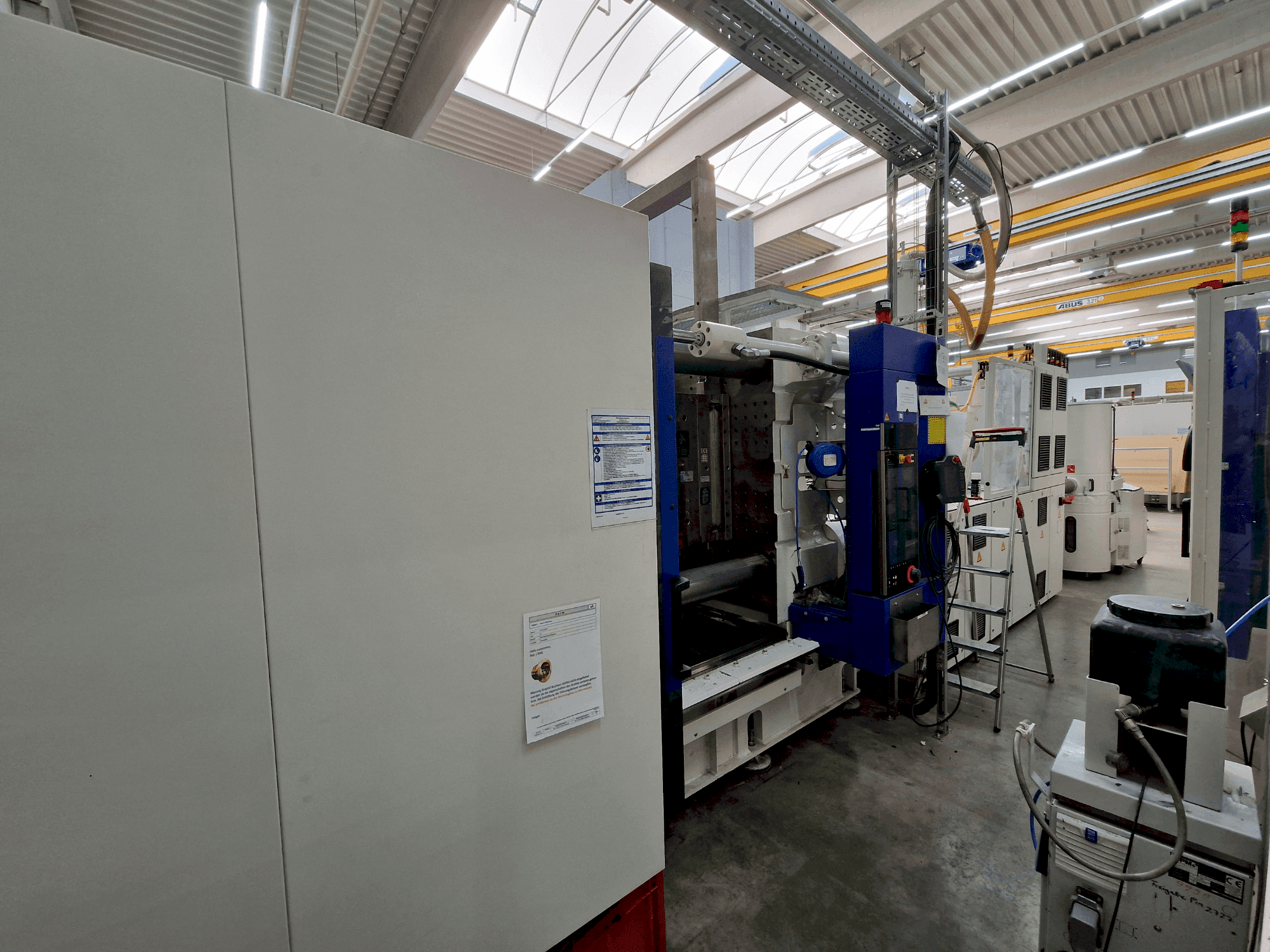

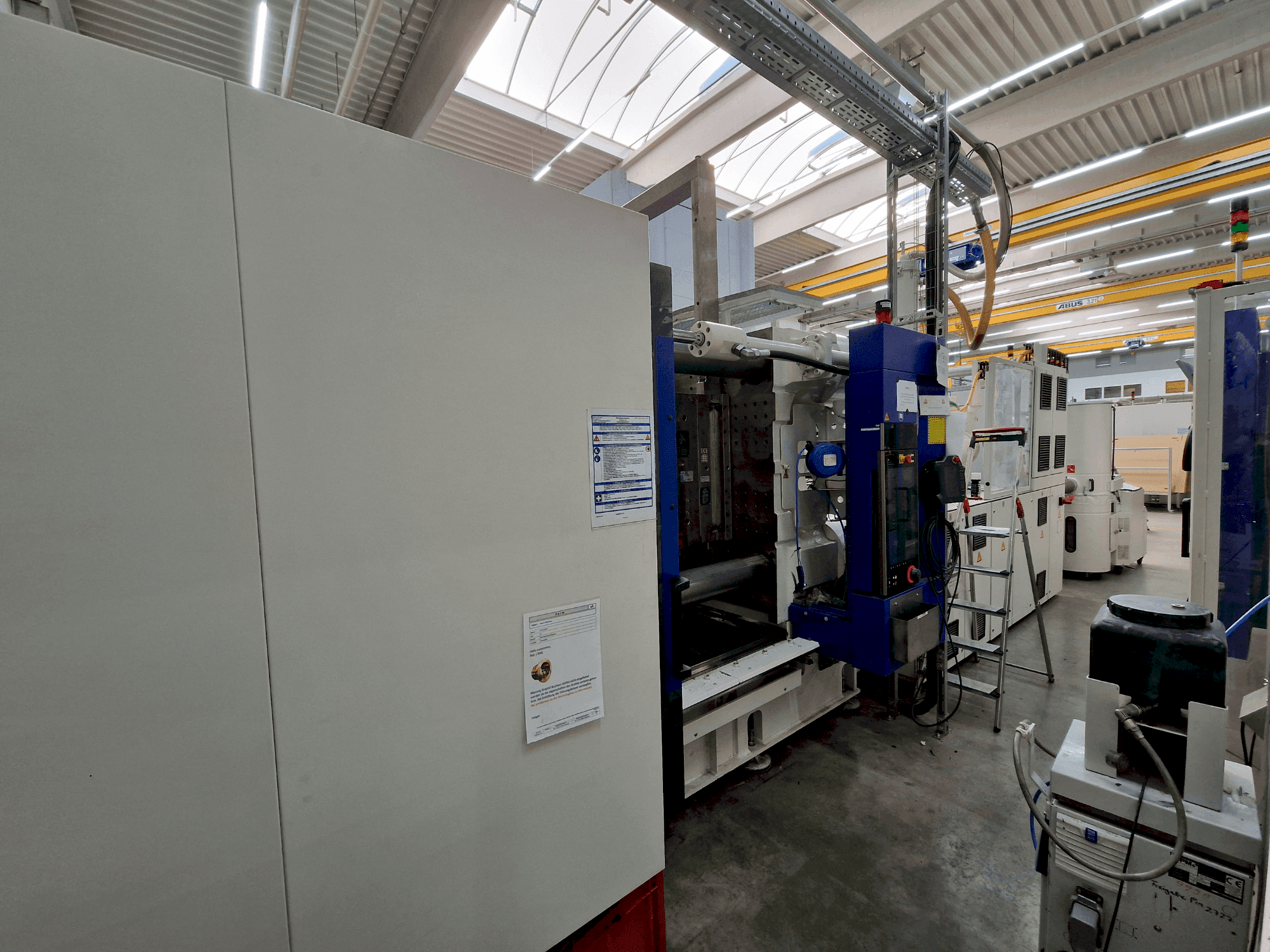

Engel - duo 2400/650DE-INJ-ENG-2019-00004

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Kunststoffverarbeitungs-Maschinen

- ➤ Gebrauchte Engel duo 2400/650 zu verkaufen | gindumac.com

Diese elektrische Spritzgießmaschine Engel duo 2400/650 wurde im Jahr 2019 hergestellt. Sie hat einen Schneckendurchmesser von 60/70/80 mm, einen Schneckenhub von 315 mm und eine maximale Einspritzleistung von 890 cm³. Die Schließkraft erreicht bis zu 6500 kN bei einem maximalen Werkzeuggewicht von 11000 kg. Erwägen Sie die Gelegenheit, diese elektrische Spritzgießmaschine Engel duo 2400/650 zu kaufen. Kontaktieren Sie uns für weitere Informationen über diese Maschine.

Übersicht

- Hersteller: Engel

- jahr: 2019

- MODELL: duo 2400/650

- anwendungstyp: Spritzgießen

- Standort: Deutschland

- maschinentyp: Elektrische Spritzgießmaschine

- Marke Steuergerät: ENGEL

Technische Daten - Engel duo 2400/650

Steuerung

- Steuerungshersteller: ENGEL

Maße

- Maschinengewicht: 6500 kg

Technische Spezifikation

- Klemmkraft: 6500 kN

- Schraubendurchmesser: 60 mm

Zusätzliche Informationen

Zusätzliche Ausstattung

Fassungsvermögen des Öltanks - Einspritzeinheit: 500 l

Maximale Kühlleistung (32°C Wasserzulauf): 29,40 kWcool

Wasserverbrauch (32°C): 4,80 m3/h

Vorteile der Maschine

Qualitative Vorteile der Maschine

Die Maschine verfügt über elektrische Wasserbatterien (4 E-Flomos mit je 8 Kreisläufen).

Die Spritzeinheiten sind mit Akkumulatoren ausgestattet, die einen hohen Einspritzdruck von bis zu 2400 bar bei einer 60 mm Schnecke ermöglichen.

Technische Vorteile der Maschine

Maximale Einspritzleistung: 890 cm³

Schneckendrehmoment: 2000 nm // maximale Schneckendrehzahl bei reduziertem Drehmoment: 275 min-1

Reduziertes Drehmoment bei maximaler Schneckendrehzahl: 1600 nm

Rückgewinnungsrate (3-Zonen-Schnecke): 51 g/s // Rückgewinnungsrate (Barriereschnecke): 67. 1 g/s

Einspritzmenge: 353 cm³/s

Düsenhub: 950 mm

Ld-Verhältnis: 24. 0

Heizzonen inkl. Düse: 8 // Heizleistung: 27. 5 kwel

Öffnungskraft mit Druckkissen: 510 kn

Maximaler Abstand zwischen den Platten: 1750 mm

Zusätzliche Informationen

Abmessungen & Gewicht

Breite des Auswurfschachtes: 1100 mm

Gewicht der Schließeinheit: 20.000 kg

Maximales Werkzeuggewicht (bewegliche Aufspannplatte): 7.330 kg

Maximales Werkzeuggewicht (stationäre Aufspannplatte): 7.330 kg

Maximales Werkzeuggewicht (gesamt): 11.000 kg

Zyklusdaten (Euromap 6)

Hub: 700 mm

Trockenzykluszeit: 2,9 s

Steuerungssystem: Monocompute CC300

Wichtigste Merkmale

21,5" Full-HD-Touchscreen

USB-Schnittstelle / Ethernet-Anschluss

E-move Bedienelement

3 Keycards zur Benutzeranmeldung

Grafische Symbole für die Zyklussteuerung

Bildschirmsprachen: Deutsch, Englisch

Akustisches Fehlersignal / Signalleuchte zur Fehleranzeige

Programme & Überwachung

Power Control: optimiert die Motorleistung während des Dosierens

Messung der Werkzeugparallelität

IQ Weight Monitor: Überwachung von Schussgewicht und Viskosität

IQ Weight Control: automatische Anpassung der Einspritzparameter bei Schwankungen

Schnittstelle zur Qualitätsüberwachung (Einspritzzeit, Dosierzeit, Druck, Zykluszeit)

Kontinuierlicher Ausstoß möglich, wenn die Überwachung deaktiviert ist

Schließeinheit & Platten

Verstärkte Aufspannplatten (FAP & BAP je +50 mm)

Reduzierte min./max. Werkzeughöhe und Plattenabstand (-100 mm durch Verstärkung)

FAP: kleinstmögliche Plattenöffnung, sphärische Kalotte minimiert

BAP: ohne Auswerferöffnung

Zusätzliche Gewinde nach EUROMAP VOL1

Zentrierrillen nach Zeichnung

Plattenauswerfer - Variante A (angepasst an das Schließbild)

Sicherheitsschnittstelle für Auswerfer

Hydraulik & Kernzüge

Hydraulischer Kernzug:

1-fach auf beweglicher Aufspannplatte

2-fach auf fester Aufspannplatte

2-fach auf beweglicher Aufspannplatte mit Proportionalventil PQ, Volumenmessung, Druck-/Geschwindigkeitseinstellung

Schnittstelle für Kernzug-Zwischenposition

Werkzeugheizung und -kühlung

Heizung der Form: 16 Kreise, max. 40 kW Heizleistung (Euromap 14)

Temperaturüberwachungsschnittstelle (bewegliche und feste Aufspannplatte)

4-fache hydraulische Werkzeugdüsensteuerung

Separater Kühlwasseranschluss (Werkzeug & Maschine)

Schnittstelle zum Temperaturregelgerät: Engel-Protokoll, 20 mA Stromschleife

4-Wege-Durchflussregler (0-10 l/min)

Schlauch-Spezifikation: max. 90 °C / 4 bar

Schläuche für Werkzeugkühlung

4 Temperaturregelkreise auf der Rückseite der Maschine

Spüldüse mit Schlauchklemme

2× ENGEL e-formo Temperiersysteme (1-15 l/min, 8 Kreise, max. 120 °C)

1 Verteiler für feste Platte, 1 für bewegliche Platte

Zusätzliche e-formo Einheit auf der Bedienseite (optional)

Antrieb & Hydraulik

ENGEL ecodrive S+V3 (drehzahlgeregelter Servoantrieb)

Geschlossenes Regelsystem für Druck & Geschwindigkeit (closed loop)

2× 50 L Hydraulikspeicher (für Sprühvorgang)

Batterieposition an der Vorderseite (gemäß Zeichnung)

Ölkühler (Standardkapazität)

Lieferung ohne Ölfüllung (Öl enthält Zink bei der Inbetriebnahme)

Geräuscharme, energieeffiziente Hydraulik mit optimierter Steuerung, Filtration, Ölvorwärmung und -kühlung

Einspritzeinheit

Bi-Metall-Zylinder (auf Fe-Basis), abriebfest und korrosionsbeständig, bis zu 350 °C

Zusätzliche Zonenheizung am Zylinder

Druckscheibe (Membrane) für Schnecke S8, Ø 60 mm, L/D 24, Geometrie G1

UNR9 RGB Rückschlagventil (pulvermetallurgischer Chromstahl)

Korrosionsbeständiger Flansch

Offene Spezialdüse, korrosionsbeständig, Flanschgewinde V445x3, Radius 15 mm, Bohrung 8 mm

Düsenausgang geeignet für Heißkanalanschluss

230 V Zylinder- und Düsenheizung

Keramische Zylinderabdeckungen

Isolierte Heizflächen (nicht geeignet für PC, PMMA, PVC, etc.)

Elektrisches System

Versorgungsspannung: 3×400 V + N + PE / 50 Hz

Schuko-Steckdosen (230 V), max. 2 Stück

3-phasige CEE-Steckdose (10/16 A)

Potentialfreie Kontakte: 4 Eingänge / 4 Ausgänge (frei programmierbar)

Schnittstellen (Euromap)

13 - Kernzug-Endlagen

14 - Heizung

63 - Online-Datenabfrage

65 - Tankberechnung

Roboter & Zubehör

ENGEL easix Roboter (KR 60, Sonderausführung)

Robotersteuerung nicht mehrfach integriert

Montage & Test bei ENGEL

Bedienungsanleitung: gedruckt + CD (deutsch)

Konformität, Design & Extras

EN 201 Konformität (Maschinensicherheit)

Lackierung: RAL 9002 (grau-weiß) & RAL 5002 (ultramarinblau), Sonderausführung ENGEL

E-connect.24 Basispaket (Fernwartung)

Maschinenfüße (Standardausführung)

Beschriftung in Deutsch

Alle 4 E-Flomo-Aggregate komplett von ENGEL erneuert

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung