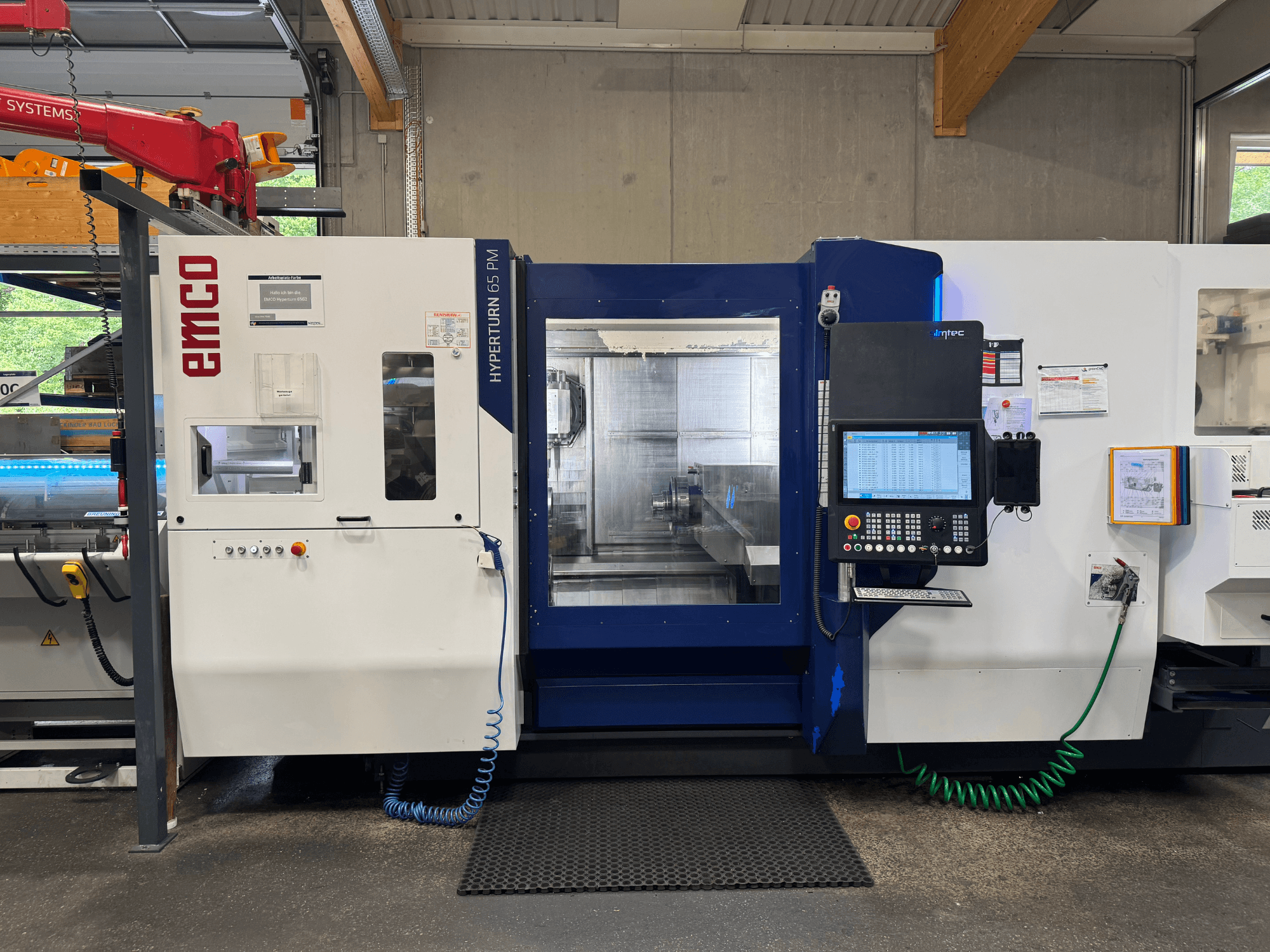

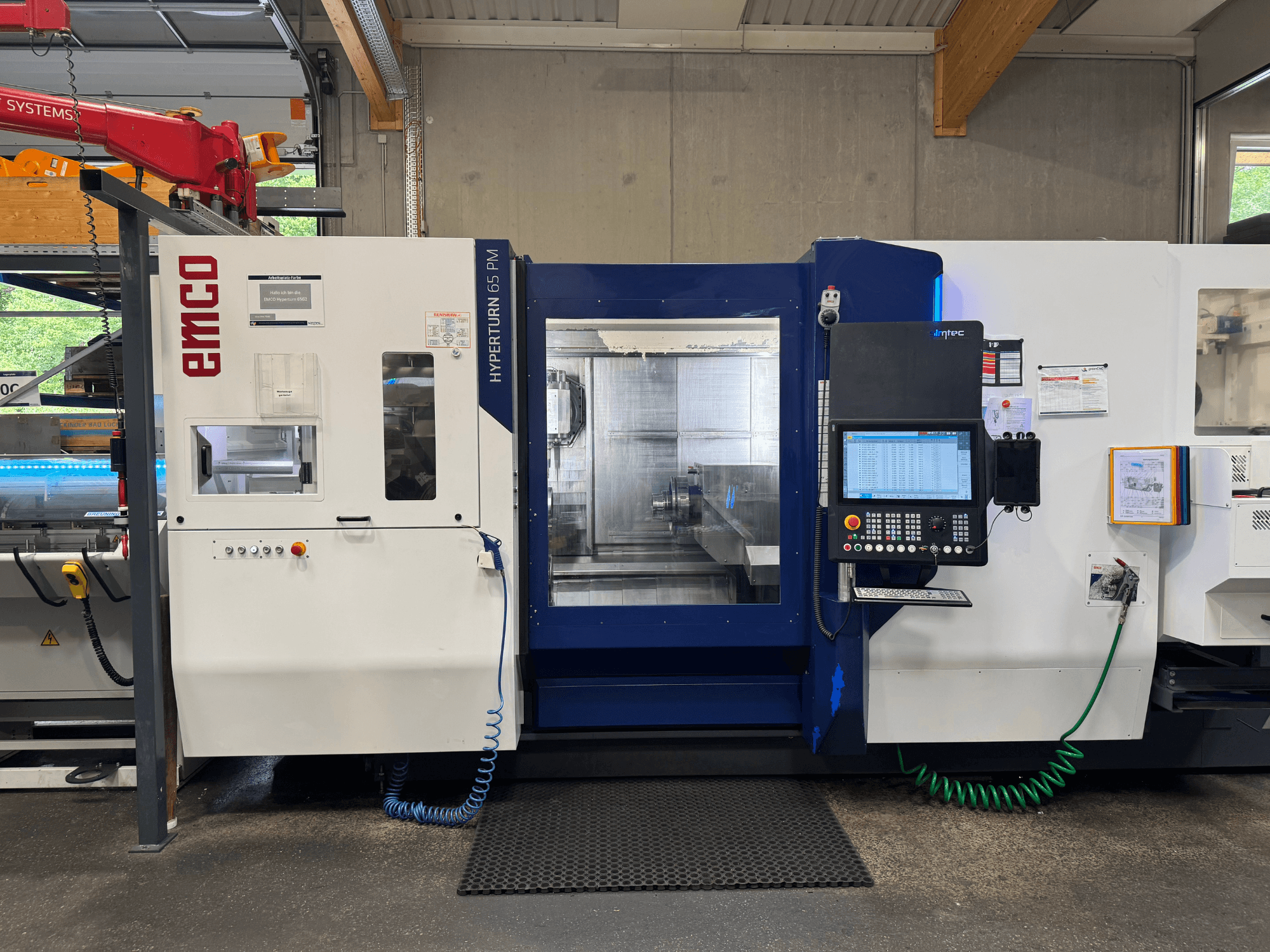

EMCO - Hyperturn 65 Powermill G2AT-TUR-EMC-2022-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- ➤ Gebrauchtes EMCO Hyperturn 65 Powermill G2 | Dreh-Fräszentrum

Diese 6-achsige EMCO Hyperturn 65 Powermill G2 wurde im Jahr 2022 hergestellt. Dieses hochproduktive CNC-Dreh-Fräszentrum verfügt über eine Haupt- und eine Gegenspindel mit einem maximalen Drehmoment von 250 Nm und Drehzahlen von bis zu 5000 U/min. Die Frässpindel bietet bis zu 12000 U/min. Sie verfügt über ein Werkzeugmagazin mit 40 Plätzen, einen Revolver mit 12 Plätzen und die moderne Sinumerik ONE-Steuerung. Wenn Sie auf der Suche nach hochwertigen Dreh- und Fräsfunktionen sind, sollten Sie die EMCO Hyperturn 65 Powermill G2 Maschine in Betracht ziehen, die wir zum Verkauf anbieten. Kontaktieren Sie uns für weitere Informationen.

Übersicht

- Hersteller: EMCO

- jahr: 2022

- MODELL: Hyperturn 65 Powermill G2

- anwendungstyp: Drehen

- Standort: Österreich

- maschinentyp: Dreh-Fräszentrum

Technische Daten - EMCO Hyperturn 65 Powermill G2

Maße

- Maschinengewicht: 620 kg

Bewegung

- Anzahl der Achsen: 6

Technische Spezifikation

- Spindelleistung: 29 kW

- Spindeldrehzahl: 5000 RPM

Zusätzliche Informationen

Hauptspindel (Direktantrieb):

Max. Drehmoment: 250 Nm

Gegenspindel (Direktantrieb):

Max. Antriebsleistung: 29 kN (wie vorgesehen)

Max. Drehmoment: 250 Nm

Drehzahlbereich: 0-5000 U/min

Frässpindel (Direktantrieb):

Max. Antriebsleistung: 37 kW

Max. Drehmoment: 30 Nm

Drehzahlbereich: 0-12000 U/min

Werkzeugrevolver (Direktantrieb):

Max. Antriebsleistung: 10 kW

Max. Drehmoment: 30 Nm

Drehzahlbereich: 0-12000 U/min

Kinematik und Achsen:

Querschlitten oben mit Dreh-/Frässpindel als Motorspindel; hydraulische Klemmung beim Drehen

Verfahrweg Y-Achse: +/- 120 mm

B-Achse mit Direktantrieb: +/- 120°, hydraulische Klemmung

Werkzeugbestückung:

Werkzeugmagazin mit 40 Plätzen, HSK-T63

12-fach Radialrevolver mit Direktantrieb, Werkzeugschnittstelle BMT55P

Spindeln und Spannen:

Hochspannzylinder mit Zugrohr für Hauptspindel

Vollspannzylinder mit Teilhohlspannung 66 x 550 mm tief in der Gegenspindel

Programmierbarer Spanndruck für Haupt- und Gegenspindel

Externe Vorschubspülung an Haupt- und Gegenspindel

Mechanische Haltebremse an Haupt- und Gegenspindel

C-Achse für Haupt- und Gegenspindel

Steuerung und HMI:

SINUMERIK ONE / OPERATE, EMCONNECT app-basierte Benutzeroberfläche

22"-Multitouch-Display

IPC mit 240 GB

SHOPTURN-Dialogprogrammierung

3D-Simulation und Zeichnen

Restmaterial-Erkennung

Entsperrung von externem Speicher

CAD-Leser (DXF-Import)

TRANSMIT und TRACYL für die Programmierung der C-Achse

USB-Schnittstelle, Netzlaufwerk (Ethernet)

PC-Tastatur inkl. HMI-Hotkey

LED-Statusanzeige

Flüssigkeiten und Betriebsmittel:

2 Kühlmittelleitungen bei 25 bar

2 Spülpumpen mit 4,3 bar

Schaltschrank-Klimagerät

Kühlsystem für Spindelmotoren, Frässpindel, Torque-Motor der B-Achse und Revolver-Direktantrieb

Hydraulische Einheit

Maschinenleuchte

8 Nivellierelemente

Rückmeldung/Messung:

Glasmaßstäbe: X1 (inkl. Luftanlage), Y1, Z1, X2 (HT65-PM-G2 / 840D-sl)

Zusätzliche Ausstattung

Spänemanagement und Filterung:

Scharnierband-Späneförderer, Abwurfhöhe 1200 mm

Bandfilteranlage, 980 Liter

Schmutzwasserpumpe

Steuerungs-/Überwachungsmöglichkeiten:

Elektronisches Handrad BAOD-SL (tragbar, Magnethalterung für Siemens-Steuerungen)

EMCO Werkzeugbruch- und Verschleißüberwachung / B40D-SL

Drahtloser Messtaster / HSK-Bohrerbruchkontrolle BK-MICRO

4-Achsen-Drehen / Wuchtschneiden (Option SINUMERIK)

Alternativ-Endspindeldrehzahl (Option SINUMERIK)

Revolver als Reitstock (SINUMERIK-Option)

Gegenspindel als Reitstock (SINUMERIK-Option)

Stangenlader (Spezifikationen wie geliefert):

Stangenlänge: 300-1200 mm

Stangendurchmesser: 10-104 mm

Materialauflagefläche (Vorderansicht): 800 x 1250 mm

Materialkapazität: 12 Stangen mit 65 mm Durchmesser

Max. Tragfähigkeit: 400 kg (max. 74 kg/Stange)

Rechteckiges Material: min. Kantenlänge 6 mm; max. Umfang 105 mm

Sechseckiges Material: SW 5 bis 85 mm

Rundes Material: <15 mm

Stangeneinzugstiefe: 1470 mm

Spannungsversorgung: 24 V DC (Schnittstelle)

Abmessungen: Länge 1800 mm; Breite 1315 mm

Schlitten-/Spindelhöhe: 1090-1330 mm

Gewicht: ca. 620 kg

Zubehör:

Spannfutter, Hainbuch Centrotex M Schnell Wechselsystem.

Axzug SE100

Axzug SE65

Axialzug SE 65

Axfix SE100

Span Dorn T210 GR0

4 Bachen Futter INOFlex® VT-S 016 ( 160 Bachen Futter)

Warenwert ca.: 70.000€

Sowie BMT 55 Halter Unten

Und 40Hsk Aufnahmen ( Warenwert ca.: 30.000)

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung