Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

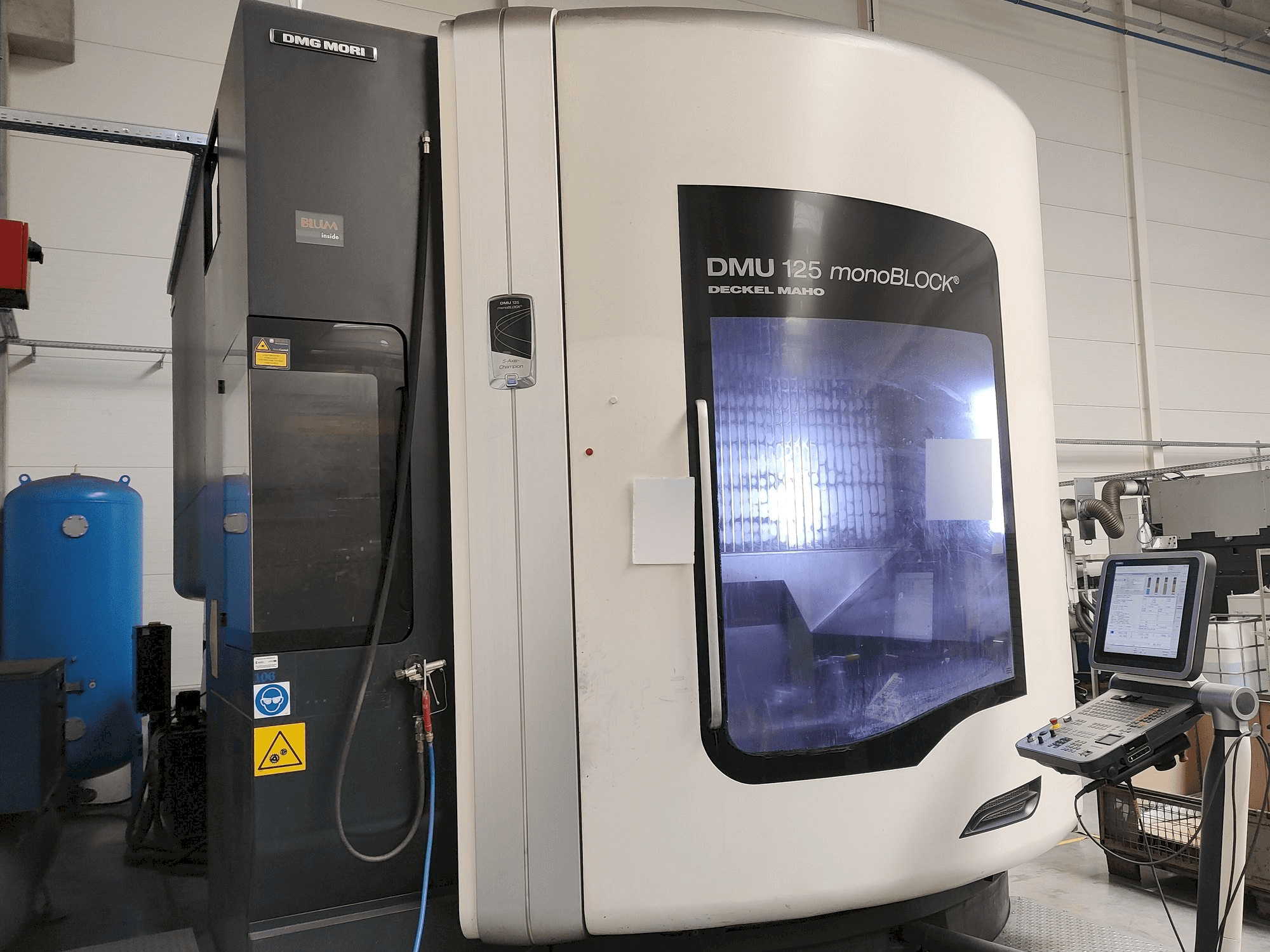

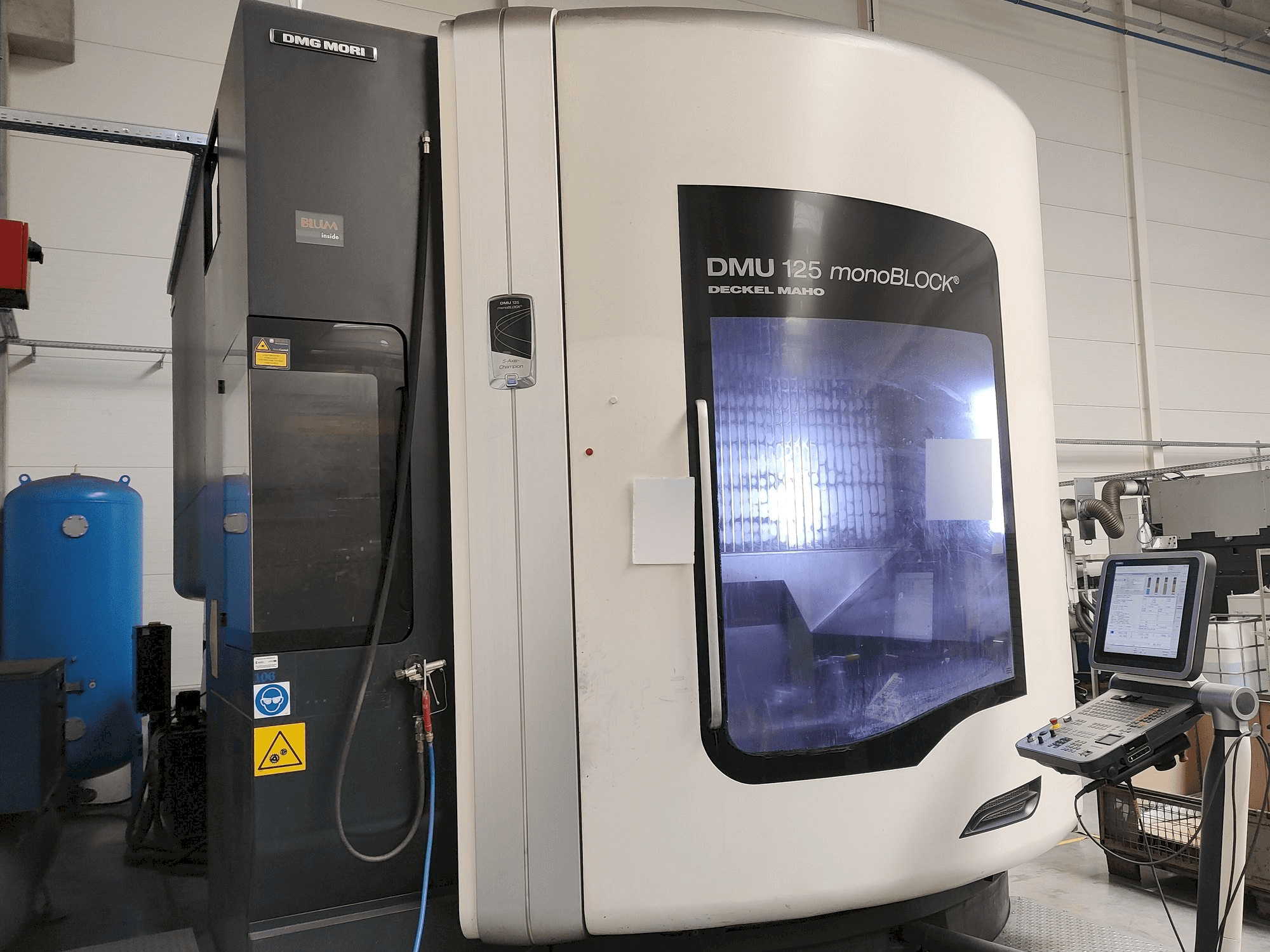

DMG MORI - DMU125 monoBLOCKPL-MIL-DMG-2014-00003

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- DMG MORI DMU125 monoBLOCK Universal Machining Center

This DMG MORI DMU125 monoBLOCK Universal Machining Center was manufactured in the year 2014 in Germany and has 44034 power on hours, of which 26404 are spindle hours. It is equipped with a Heidenhain 3D iTNC 530 HSCI control unit and has 5 axis. The machine has a spindle speed of 18000 rpm, is in very good condition and well maintained.

Übersicht

- Hersteller: DMG MORI

- jahr: 2014

- MODELL: DMU125 monoBLOCK

- Produktionsstunden: 44034

- anwendungstyp: Fräsen

- Standort: Polen

- maschinentyp: Universal-Bearbeitungszentrum

- Marke Steuergerät: HEIDENHAIN

Technische Daten - DMG MORI DMU125 monoBLOCK

Steuerung

- Steuerungsmarke: HEIDENHAIN

- Steuerungsmodell: 3D iTNC 530 HSCI

Maße

- Maschinentiefe: 6629 mm

- Maschinenhöhe: 3910 mm

- Maschinengewicht: 23700 kg

Bewegung

- Anzahl der Achsen: 5

- X-Achsverfahrweg: 1335 mm

- Y-Achsverfahrweg: 1250 mm

- Z-Achsverfahrweg: 900 mm

Technische Spezifikation

- Spindeldrehzahl: 18000 RPM

- Werkzeugaufnahme: SK 40

Zusätzliche Informationen

Machine Benefits

Qualitative Machine Benefits

- Machine in very good, working condition, ready for tests. Full history service.

- Laser vertical measurement of tool length and diameter.

- 3d quickset toolkit for checking and compensating the kinematic accuracy of the machine in a 4/5 axis configuration

- Mpc protection of the machine tool by immediate shutdown

- Coolant tank 600 l paper filter internal coolant feed 40 bar / 23 l / min through the center of the spindle

- Coolant nozzles for vertical headstock 15 nozzles for liquid, 5 for air separator for oil or emulsion mist mechanical filter capacity 1,100 m3 / h

- Tuning cycle atc 4,160. 00 programmable setting of feed parameters

- Grid platforms for easier access to machining area operating mode 4 "process monitoring in production"

- Wide working range for workpieces up to ø 1. 440 mm, 790 mm height and max. 2. 600 kg, with swivel rotary table, as well as workpieces up to 1. 600 × 1. 440 × 790 mm and max. 6. 000 kg with rigid table

- Loading by crane from above up to over the table center as standard accessibility and ergonomics: door opening 1. 900 mm, tool loading during the main time and complete accessibility from the front lowest footprint with 25 m² installation area

Technical Machine Benefits

- Max workpiece height: 790 mm

- Tool clamping to din 69872

- Vertical headstock

- Tool change system double gripper

- Chain tool magazine with 30 pockets, sk 40

- Worktable

- Nc swivel rotary table tandem drive table plate c-axis: d 1,250 x

- 1,000 mm integrated in rigid table 1,400 mm x 1,000 mm in 1x t-slot 14 permissible load: 2,600 kg

- Bore pattern 8 x m12 rotation c axis: 360°swivel range a-axis: -120°/-120° drive a axis: gantry / tandem drive (basic machine without swivel rotary table)

- Renishaw infrared measuring probe pp60 optical (omp 60) sk 40 tool measurement in the blum workspace.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung