Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

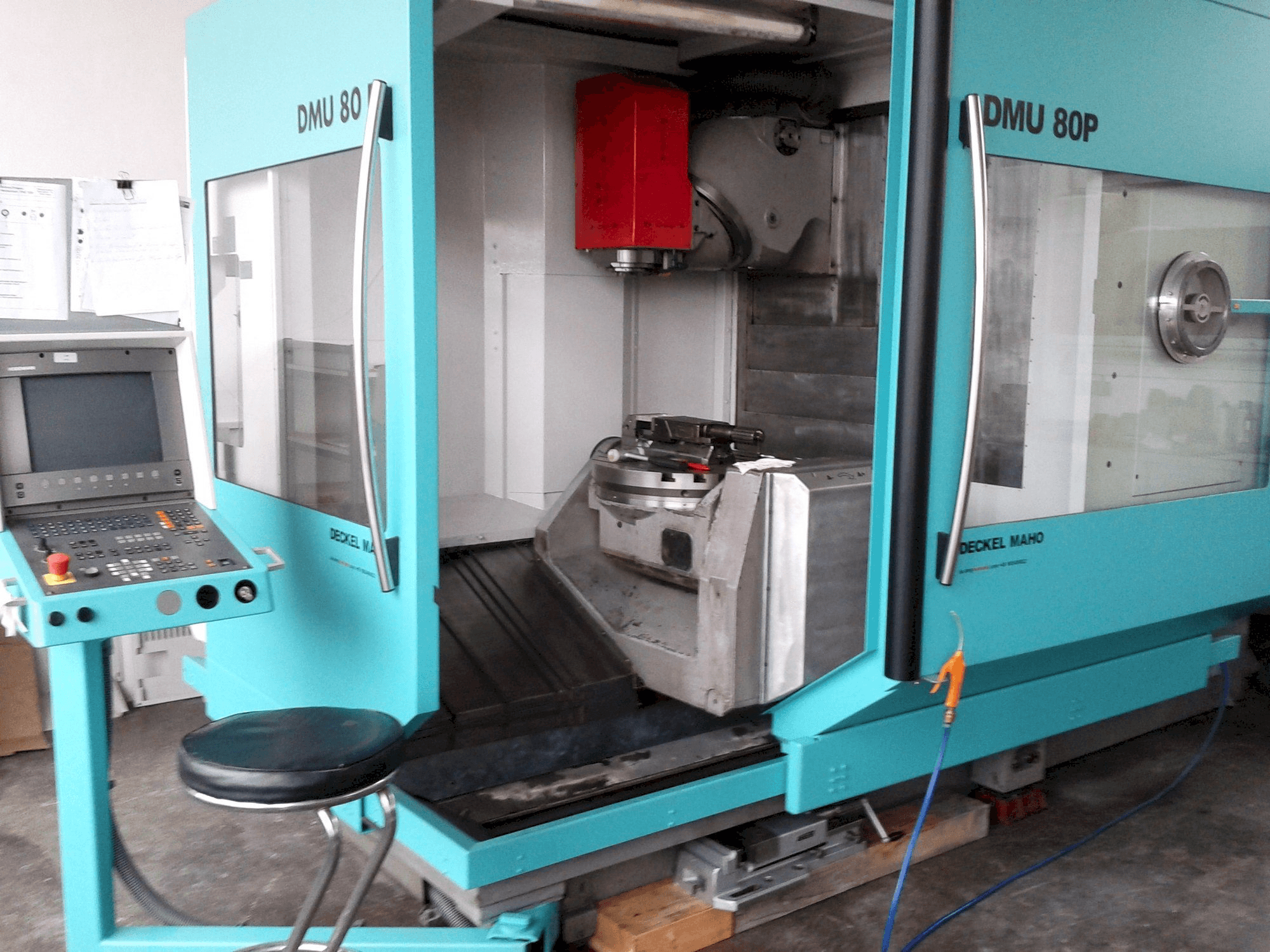

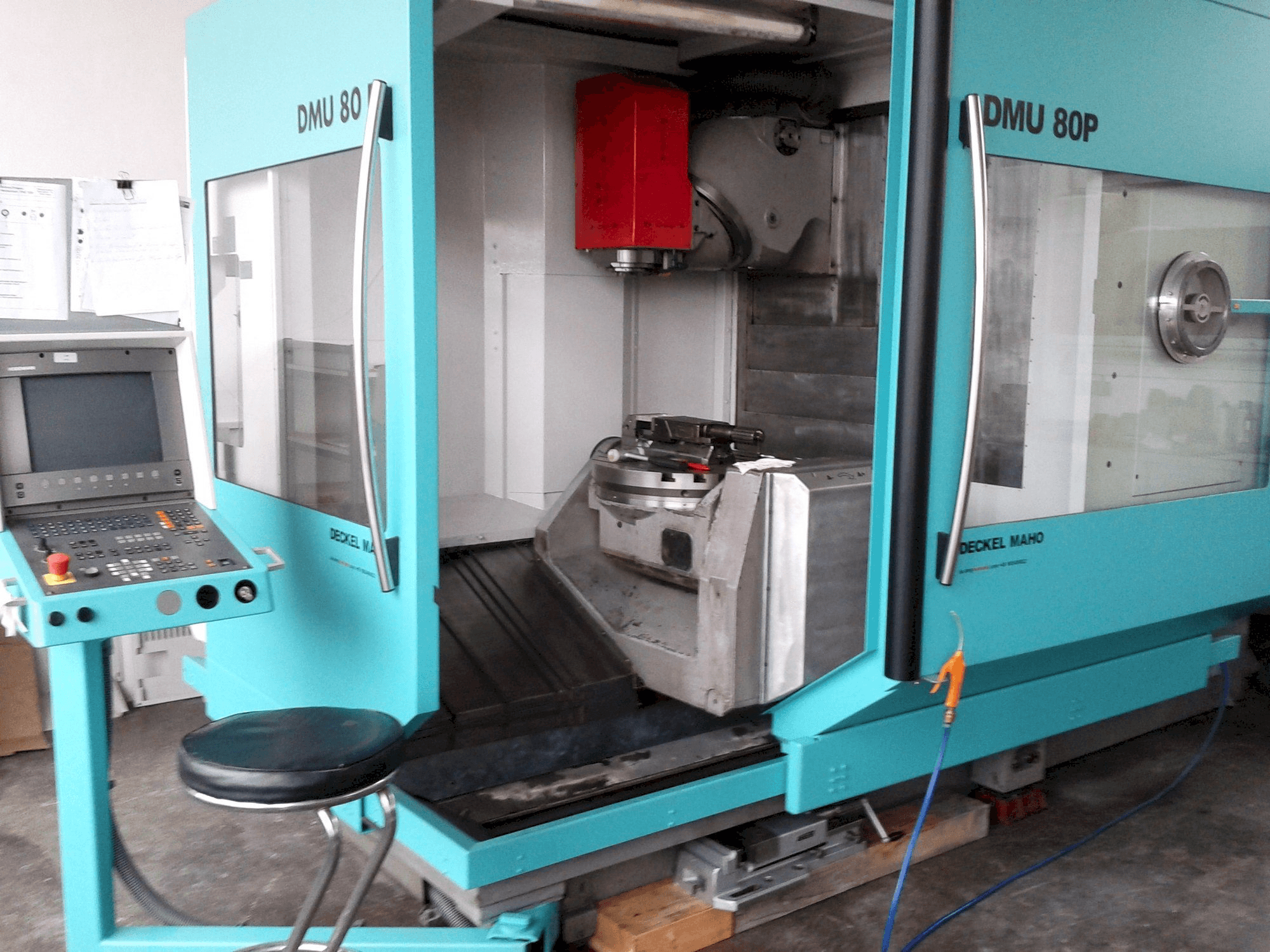

DECKEL MAHO - DMU 80PDE-MIL-DEC-1999-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- DECKEL MAHO DMU 80P Universal Machining Center

This DECKEL MAHO DMU 80P Universal Machining Center was built in the year 1999 and has been working for 56145 hours, from which 27389 are spindle hours. This machine is in a very good condition and can be tested under power. Its table, as well as the tool clamps, were overhauled and got a Heidenhain LE426PB swap computer with a fast SSD hard disk. The Siemens Simodrive LT-Module Interface 108A Type: 6SN1123-1AA00-0LA1 has been exchanged. Also, the spindle encoder has been exchanged. The zero position must be adjusted once a day. The side window has a crack but this does not affect functionality. Many tool holders are converted to IK. Aluminium cover strips has been renewed on the side. Inside and outside include a new spindle cover, and new inscriptions received. New switch on button green. The control panel has got handles. Valve hoses partly renewed. Hydraulic pump sound insulated. New LED tube light.

Übersicht

- Hersteller: DECKEL MAHO

- jahr: 1999

- MODELL: DMU 80P

- Produktionsstunden: 27389

- anwendungstyp: Fräsen

- Standort: Deutschland

- maschinentyp: Universal-Bearbeitungszentrum

- Marke Steuergerät: HEIDENHAIN

Technische Daten - DECKEL MAHO DMU 80P

Steuerung

- Steuerungsmarke: HEIDENHAIN

- Steuerungsmodell: TNC430

Bewegung

- A-Achse Max: 45°

- C-Achse: 360°

- X-Achsverfahrweg: 800 mm

- Y-Achsverfahrweg: 700 mm

- Z-Achsverfahrweg: 600 mm

Technische Spezifikation

- Max. Werkzeuggewicht: 630 kg

- Spindeldrehzahl: 8000 RPM

- Kühlmittelzufuhr durch die Spindel: Ja

Zusätzliche Informationen

Additional equipment

- 50 tool holders

- Tools

Machine Benefits

Qualitative Machine Benefits

- Air pressure controller with filter

- New led tube light

- Hydraulic pump sound insulated

- Valve hoses partly renewed

- New switch on button green. The control panel has got handles

- Inside and outside incl. Spindle cover new painted and new inscriptions received

- Aluminium cover strips has been renewed on the side

- Many tool holders converted to ik

Technical Machine Benefits

- Electronic handwheel

- 5 water jets and 5 air jets

- Spindle with internal cooling and tool magazine 30x

- Tlc software version: gr472. 01r

- Nc software version: 280476-29

- Coolant tank 600 litres

- Coolant pressure 20-40 bars

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung