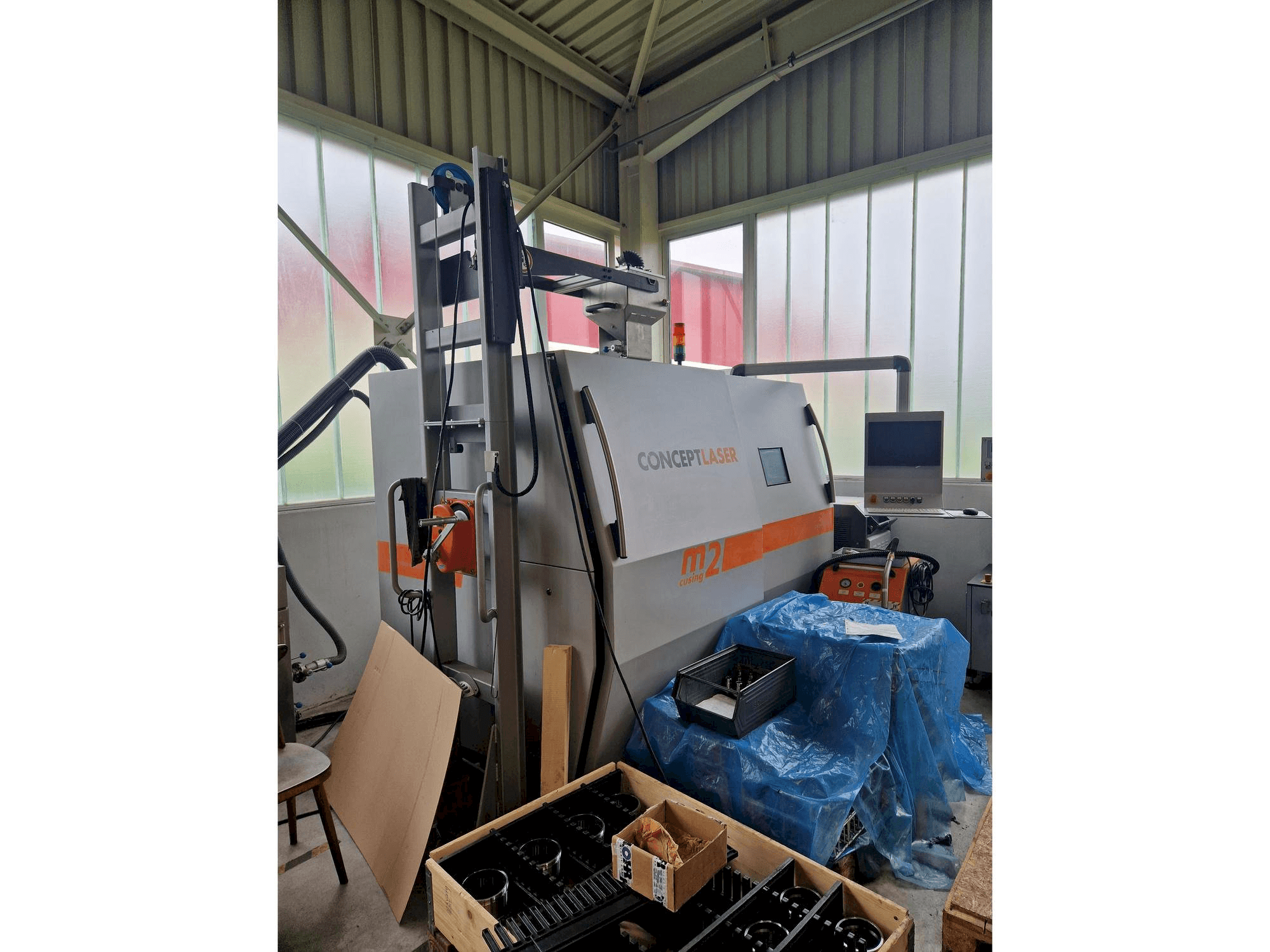

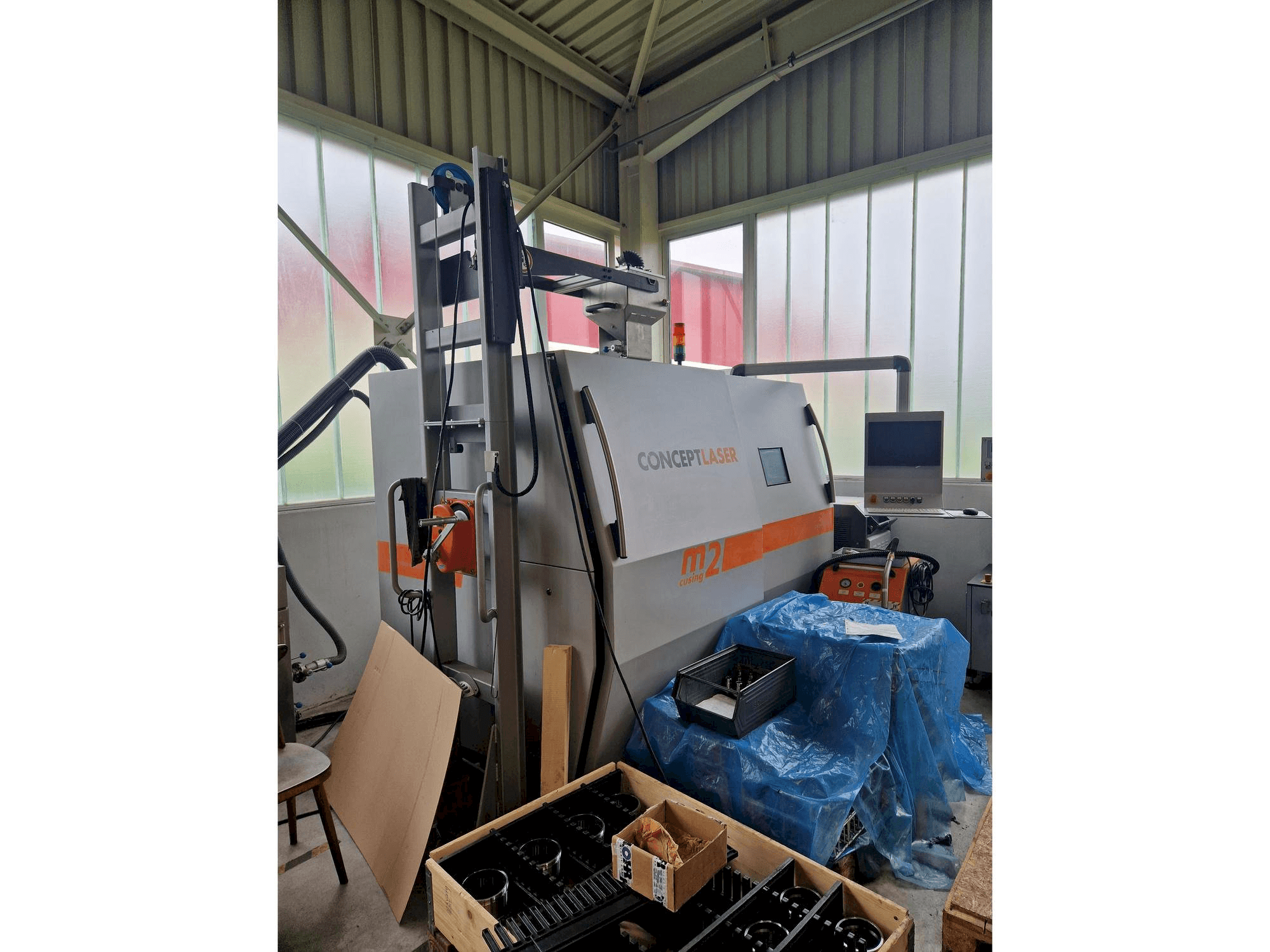

CONCEPT LASER - Laser M2 cusingDE-3DP-CON-2015-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- Concept Laser M2 cusing 3D Printer

This Concept Laser M2 cusing 3D Printer was manufactured in the year 2015.

Übersicht

- Hersteller: CONCEPT LASER

- jahr: 2015

- MODELL: Laser M2 cusing

- anwendungstyp: 3D-Druck

- Standort: Deutschland

- maschinentyp: Metall-3D-Drucker

Technische Daten - CONCEPT LASER Laser M2 cusing

Maße

- Maschinentiefe: 5900 mm

- Maschinenhöhe: 3009 mm

- Maschinengewicht: 2240 kg

Zusätzliche Informationen

Machine Benefits

Technical Machine Benefits

Exposure field: 90x90 mm

Installation height: 100 mm

Wavelength: 1070 mm

Performance: 200 - 400w

Weight:

Total weight: approx. 2,240 kg

Machine M2 cusing: approx. 2,000 kg

Laser system: approx. 170 kg

Extraction and filter unit: approx. 70 kg

Dimensions (in mm):

Total system: approx. 5,900 (L) × 4,200 (W) × 3,009 (H)

Machine M2 cusing: approx. 2,440 (L) × 1,630 (W) × 2,354 (H)

Laser system: approx. 610 (L) × 1,200 (W) × 1,120 (H)

Extraction and filter unit: approx. 550 (L) × 550 (W) × 1,450 (H)

Standard version:

Build chamber dimensions: 250 × 250 × 280 mm (L × W × H)

Dosing chamber dimensions: 250 × 250 × 280 mm (L × W × H)

Building chamber volume: approx. 18 dm³

Dosing chamber volume: approx. 18 dm³

Building height: 280 mm plus build plate thickness

Exposure area: 245 × 245 mm

Building chamber reduction (100 mm):

Building chamber dimensions: 100 × 100 × 100 mm

Dosing chamber dimensions: 100 × 100 × 100 mm

Building chamber volume: approx. 1 dm³

Dosing chamber volume: approx. 1 dm³

Building height: 100 mm Plus build plate thickness

Exposure area: 90 × 90 mm

Building space reduction (80 mm):

Building chamber dimensions: 80 × 80 × 100 mm

Dispensing chamber dimensions: 80 × 80 × 100 mm

Building chamber volume: approx. 0.64 dm³

Dispensing chamber volume: approx. 0.64 dm³

Building height: 100 mm plus build plate thickness

Exposure area: 70 × 70 mm

Building space reduction (50 mm):

Building chamber dimensions: 50 × 50 × 100 mm

Dispensing chamber dimensions: 50 × 50 × 100 mm

Building chamber volume: approx. 0.25 dm³

Dispensing chamber volume: approx. 0.25 dm³

Building height: 100 mm plus build plate thickness

Exposure area: 40 × 40 mm Dispensing chamber extension

Building chamber dimensions: 250 × 250 × 280 mm (L × W × H)

Dispensing chamber dimensions: 250 × 250 × 480 mm (L × W × H)

Building chamber volume: approx. 18 dm³

Dispensing chamber volume: approx. 30 dm³

Building height: 280 mm plus build plate thickness

Exposure area: 245 × 245 mm

Electrical connections:

Power connection: 3/N/PE AC 400 V, 32 A

Power consumption, max.: 7.4 kW

Network connection: Ethernet 100 MB/s, machine connection: RJ45 socket

Compressed air connection:

Gas pressure: 6–10 bar

Quality: DIN ISO 8573-1 Class 1.6.1

Maximum flow rate: 100 l/min

Inert gas connection (argon):

Gas pressure: 5 bar

Purity: ≥ 3.0

Inert gas connection (nitrogen):

Gas pressure: 5 bar

Purity: ≥ 2.5

Performance data

Production speed: 2 cm³/h to 20 cm³/h (material-dependent)

Scanning speed: max. 7 m/s

LaserCUSING® layer thickness: 20 µm – 50 µm

Shielding gas consumption: approx. 2 m³/h

Laser system

Laser type: Fiber laser 200F or 400F

Protection class: Laser protection class 4

Power: max. 200 W 400 W (CW operation)

Wavelength: 1,070 nm (infrared)

Laser beam diameter: 50 µm

Environmental conditions

Storage and transport temperature: -20 to 35 °C (-4 to 95 °F)

Operating temperature: 15 to 35 °C (59 to 95 °F)

Temperature change: max. 2 °C/h (2 °F/h)

Relative humidity: max. 80% (non-condensing)

Installation altitude: max. 2,000 m above sea level

Accessoires included:

Sieve and shaker, nitrogen generator, buffer tank, wet vacuum cleaner for powder, filter system, 5 pressure plates

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Unterlagen

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung