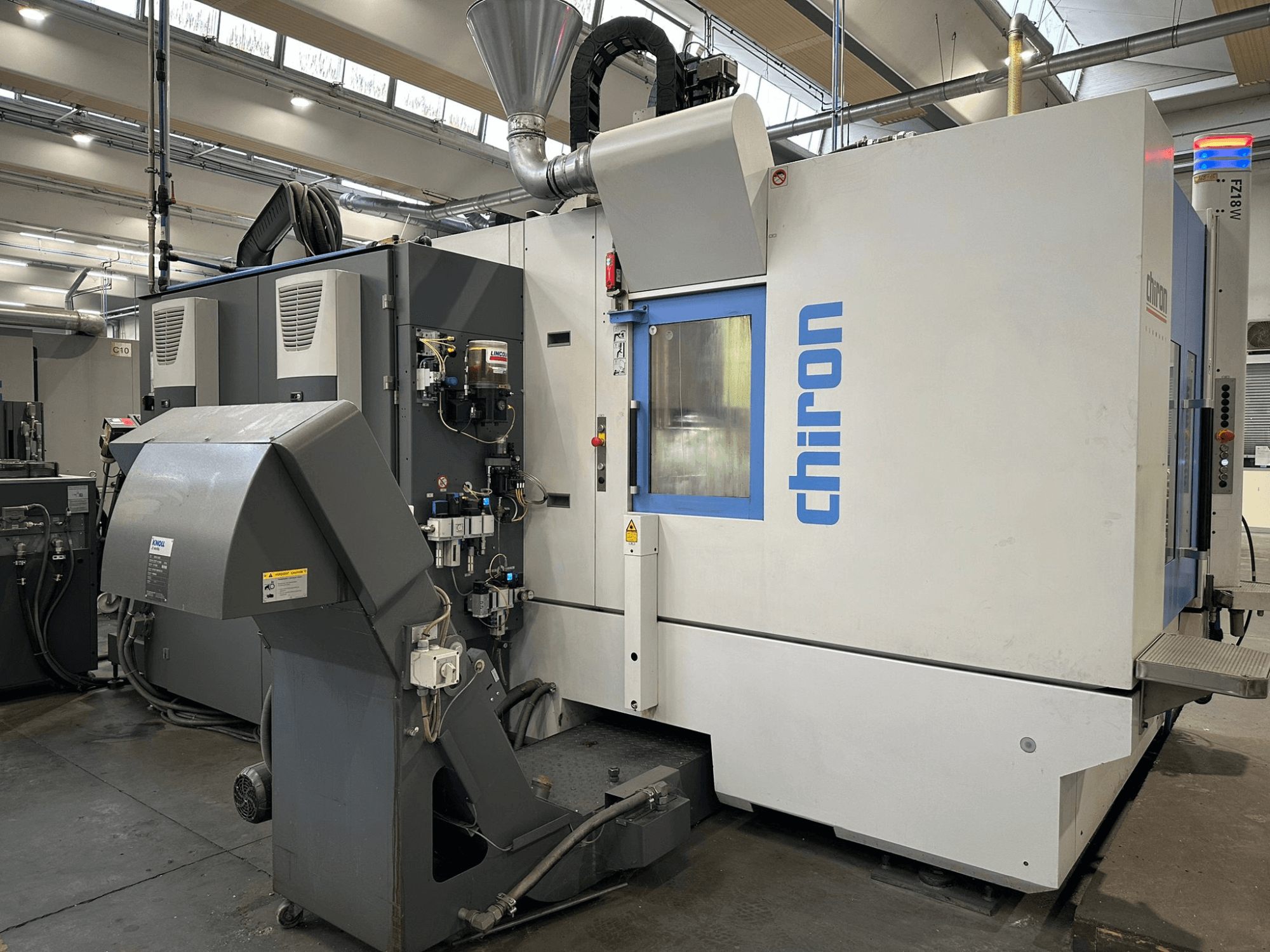

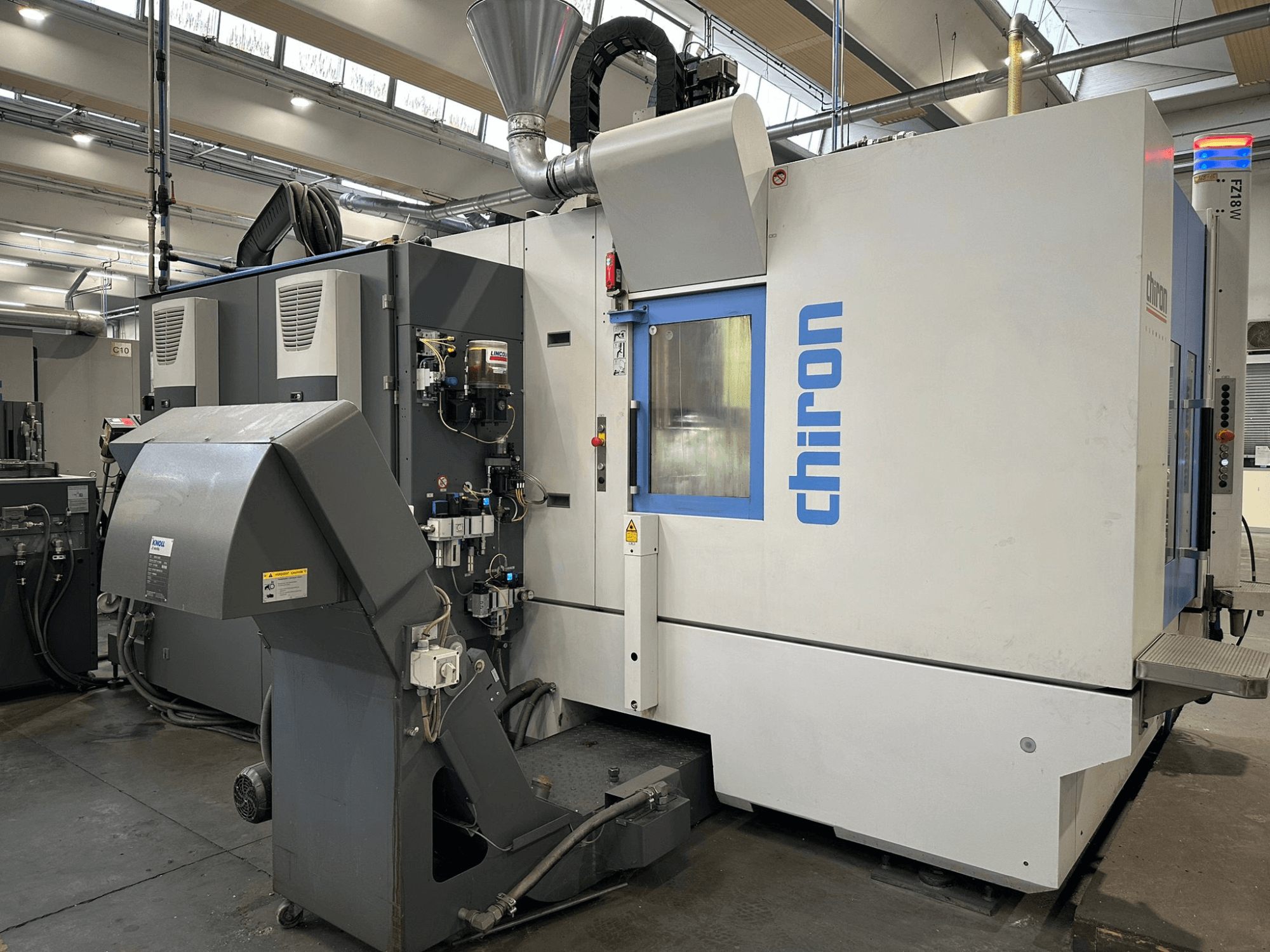

CHIRON - FZ18WIT-MIL-CHI-2019-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- ➤ Gebrauchte CHIRON FZ18W zu verkaufen | gindumac.com

Diese 5-Achsen-CHIRON FZ18W wurde 2019 hergestellt und ist mit einer FANUC 31i-B5-Steuerung und einer kontinuierlichen 5-Achsen-Steuerung ausgestattet. Sie verfügt über eine Spindeldrehzahl von bis zu 12.000 U/min, eine Werkzeugkapazität von 70 und Eilganggeschwindigkeiten von 75 m/min. Mit ihrem automatischen Palettenwechsler und den beiden Rundtischen ist sie ideal für komplexe Bearbeitungsaufgaben. Wenn Sie auf der Suche nach einer hochwertigen Fräsmaschine sind, sollten Sie die CHIRON FZ18W in Betracht ziehen, die wir zum Verkauf anbieten. Kontaktieren Sie uns für weitere Informationen.

Übersicht

- Hersteller: CHIRON

- jahr: 2019

- MODELL: FZ18W

- anwendungstyp: Fräsen

- Standort: Italien

- maschinentyp: Vertikal-Bearbeitungszentrum

- Marke Steuergerät: FANUC

Technische Daten - CHIRON FZ18W

Steuerung

- Steuerungshersteller: FANUC

- Steuerungsmodell: 31i-B5

Bewegung

- Anzahl der Achsen: 5

- X-Achsen-Verfahrweg: 800 mm

- Y-Achsen-Verfahrweg: 530 mm

- Z-Achsen-Verfahrweg: 450 mm

Technische Spezifikation

- Max. Tool Weight: 8 kg

- Spindelleistung: 22 kW

- Spindeldrehzahl: 12000 RPM

Zusätzliche Informationen

Anzahl der Achsen: 5 (X, Y, Z + 2 Drehachsen über Palette/Rundtisch)

Spindel:

AC-Spindelmotor: 7,5 kW (100% Einschaltdauer), 22,0 kW (10% Einschaltdauer)

Maximales Drehmoment: 140 Nm

Kegel: HSK-A63 (DIN 69893)

Kapazität der Bohrung: Ø 42 mm

Kapazität des Gewindeschneidens: M30

Fräsleistung: 500 cm³/min (Stahl E355)

Werkzeugwechsler:

Typ: Vollständig geschlossenes Kettenmagazin

Kapazität: 70 Werkzeuge

Max. Werkzeug-Ø: 78 mm (160 mm mit freien Nebenplätzen)

Maximale Werkzeuglänge: 380 mm

Maximale Magazinbelastung: 240 kg

Werkzeugwechselzeit: ~0,9 s

Span-zu-Span-Zeit: ~2,6 s

Vorschubgeschwindigkeiten & Dynamik:

Eilgang (X/Y/Z): 75 m/min

Beschleunigung: 0.6 - 1.2 - 1.4 g

Antriebe: Digitale Direktantriebe mit absolutem Messsystem

Maschinenfunktionen/Hilfsmittel:

Automatische Spülung von Arbeitsbereich und Vorrichtungen

Automatische Zentralschmierung mit Fett

Hydraulikaggregat: 200 bar

Druckluftaufbereitung mit Filterung bis 0,01 µm

Kühleinheit für Maschinenkomponenten

Messung, Überwachung, Software:

FANUC 3D-Kollisionskontrolle

Werkzeugüberwachung und Schwesterwerkzeugverwaltung

Elektrisch & Schnittstellen:

Ethernet RJ45, USB, PCMCIA

Ferndiagnose: CHIRON remoteLine

Datenüberwachung & OEE: CHIRON dataLine

Konformität: CE

Zusatzgeräte (Roboter, Automation, Peripheriegeräte)

Automatisierung/Palettierung:

Automatischer Palettenwechsler IWV 0°/180° (Wechselzeit ~3,5 s)

Drehtisch ATU 200, 2 Einheiten

Positioniergenauigkeit/Wiederholbarkeit: ±5″.

Maximales Spannmoment: 1.200 Nm

Maximale Last pro Seite (APC): 250 kg

Max. Gewichtsunterschied zwischen Paletten: 0 kg

Kühlmittel- und Spänemanagement:

Kühlmittel durch die Spindel (Prädisposition)

Hochdruck-Kühlmittelsystem bis zu 30 bar

Kühlschmierstoff-Filterung: Trommelfilter TPF 350 S (50 µm)

Späneförderer: Scharnierband

Kühlmittelbehälter: 230 L

Pumpe: 250 L/min @ 1,4 bar

Antasten/Werkzeugkontrolle:

Renishaw RLP40Q Messtaster (Prädisposition)

Laser-Werkzeugbruchkontrolle (Single F1000)

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung