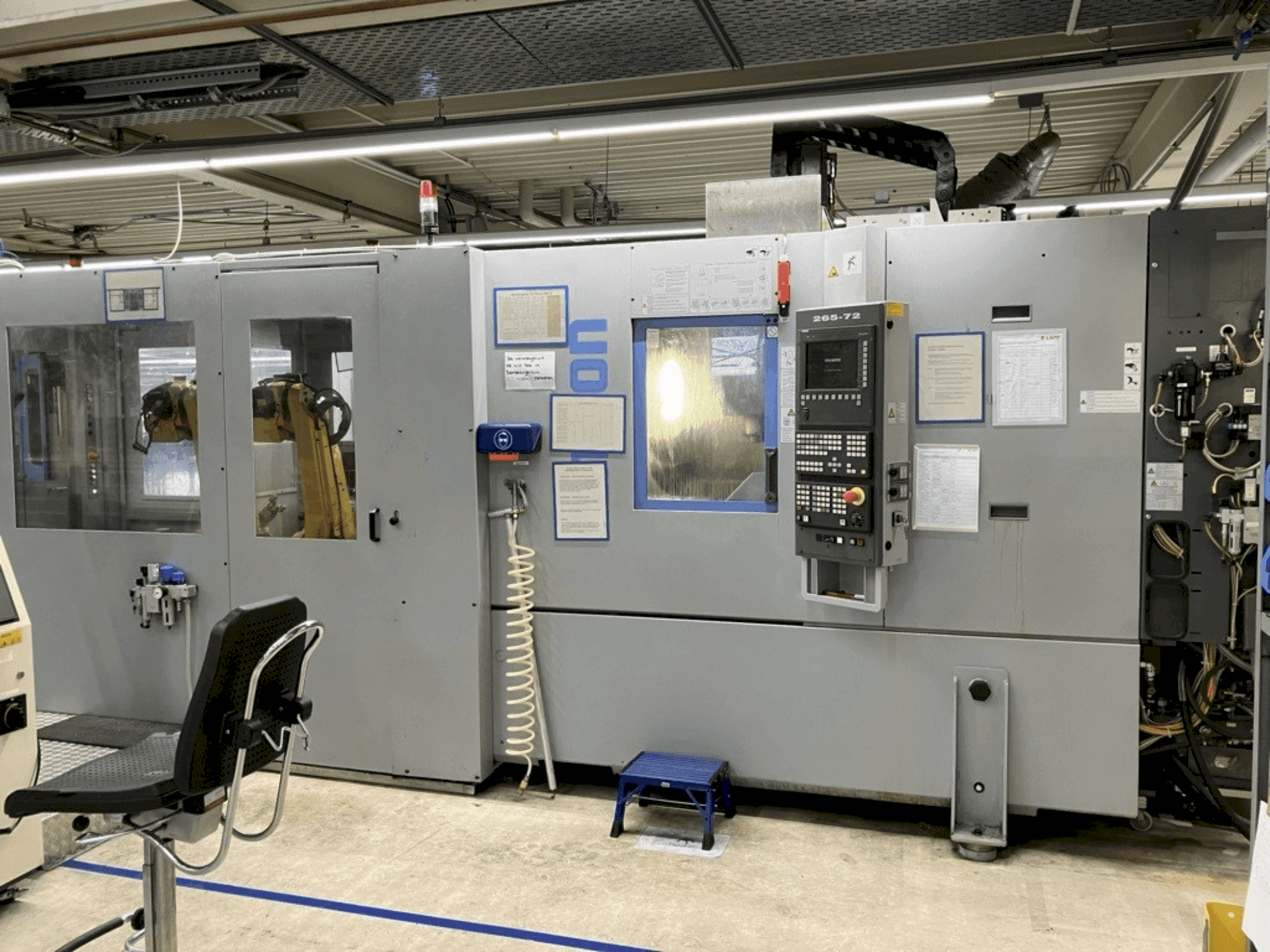

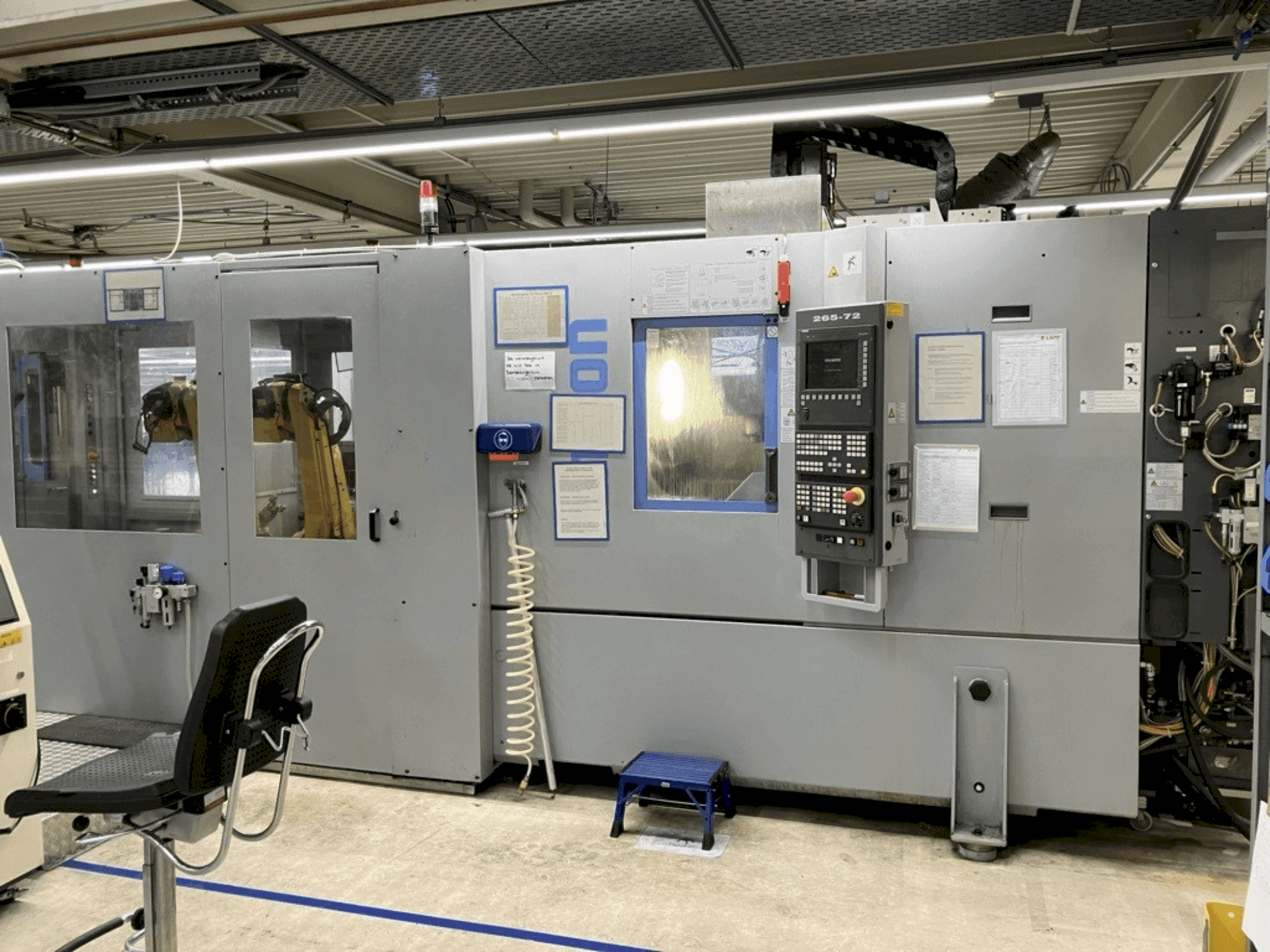

CHIRON - FZ 12 KWDE-MIL-CHI-2012-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- ➤ Gebrauchte CHIRON FZ 12 KW zu verkaufen | gindumac.com

Dieses 3-Achs-Vertikal-Fertigungszentrum CHIRON FZ 12 KW wurde im Jahr 2012 hergestellt. Es verfügt über eine Hochgeschwindigkeitsspindel mit einer maximalen Drehzahl von 12.000 U/min und einer Eilganggeschwindigkeit von bis zu 60 m/min in der Z-Achse. Die Maschine verfügt über einen automatischen Werkzeugwechsler mit 24 Plätzen und kann eine Tischlast von bis zu 500 kg bewältigen. Ideal für Präzisionsbearbeitungsaufgaben. Kontaktieren Sie uns für weitere Informationen zu dieser Maschine.

Übersicht

- Hersteller: CHIRON

- jahr: 2012

- MODELL: FZ 12 KW

- anwendungstyp: Fräsen

- Standort: Deutschland

- maschinentyp: Vertikal-Bearbeitungszentrum

Technische Daten - CHIRON FZ 12 KW

Maße

- Tischbelastung: 500 kg

Bewegung

- Anzahl der Achsen: 3

- X-Achsen-Verfahrweg: 550 mm

- Y-Achsen-Verfahrweg: 320 mm

- Z-Achsen-Verfahrweg: 360 mm

Technische Spezifikation

- Max. Tool Weight: 5 kg

- Spindeldrehzahl: 12000 RPM

Zusätzliche Informationen

Maschinenvorteile

Technische Maschinenvorteile

- Gesteuerte achsen: 6 achsen

- Reichweite: 704 mm

- Beschleunigung/abbremsung: 0 bis 12000 min-1 in 0,6 sekunden

- Aufspannfläche: 820 x 440 mm²

- Bohrleistung in st 60: Ø 16 mm

- Anzapfen: m 16

- Fräsleistung in st 60: 80 cm³/min

- Beschleunigung: x & y achse 0. 7 g, z achse 1. 0 g

Zusätzliche Informationen

Bewegung Bereich und Geschwindigkeit der Achsenbewegung: J1: 340°/360° (Option) bei 350°/s J2: 200° bei 350°/s J3: 388° bei 400°/s J4: 380° bei 450°/s J5: 240° bei 450°/s J6: 720° bei 720°/s Zulässiges Lastmoment: J4 & J5: 11,9 Nm J6: 6,7 Nm Reproduzierbarkeit: +/- 0,02 mm Maximale Geschwindigkeit J1: 195°/s J2: 175°/s J3: 180°/s J4 und J5: 400°/s J6: 600°/s Zulässiges Lastmoment J4 und J5: 7,7 Nm J6: 9,8 Nm Werkzeuge Automatischer Werkzeugwechsler: Werkzeugfächer: 24 Werkzeugwechselzeit: ca. 0,9 s Span-zu-Span-Zeit: ca. 2,4 s Die Werkstücke werden über ein automatisches Zuführsystem zugeführt und von zwei Fanuc-Industrierobotern sequentiell in die Chiron-Bearbeitungszentren geladen. Nach Beendigung der Bearbeitungsprozesse werden sie wieder entnommen. Anschließend übergeben die Roboter die Bauteile an ein Transfersystem, das sie zur nachgeschalteten Reinigungsanlage transportiert. Die integrierte Waschstraße sorgt für eine zuverlässige Reinigung der Bauteile gemäß den definierten Sauberkeitsvorgaben. Nach dem Waschprozess übernehmen zwei synchron arbeitende Fanuc-Roboter die gereinigten Teile im hinteren Teil der Anlage. Je nach Prozessvorgabe werden diese entweder automatisch palettiert oder in einem nachgelagerten Schritt, zum Beispiel durch Nieten, weiterverarbeitet. Die gesamte Anlage arbeitet vollautomatisch.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung