Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

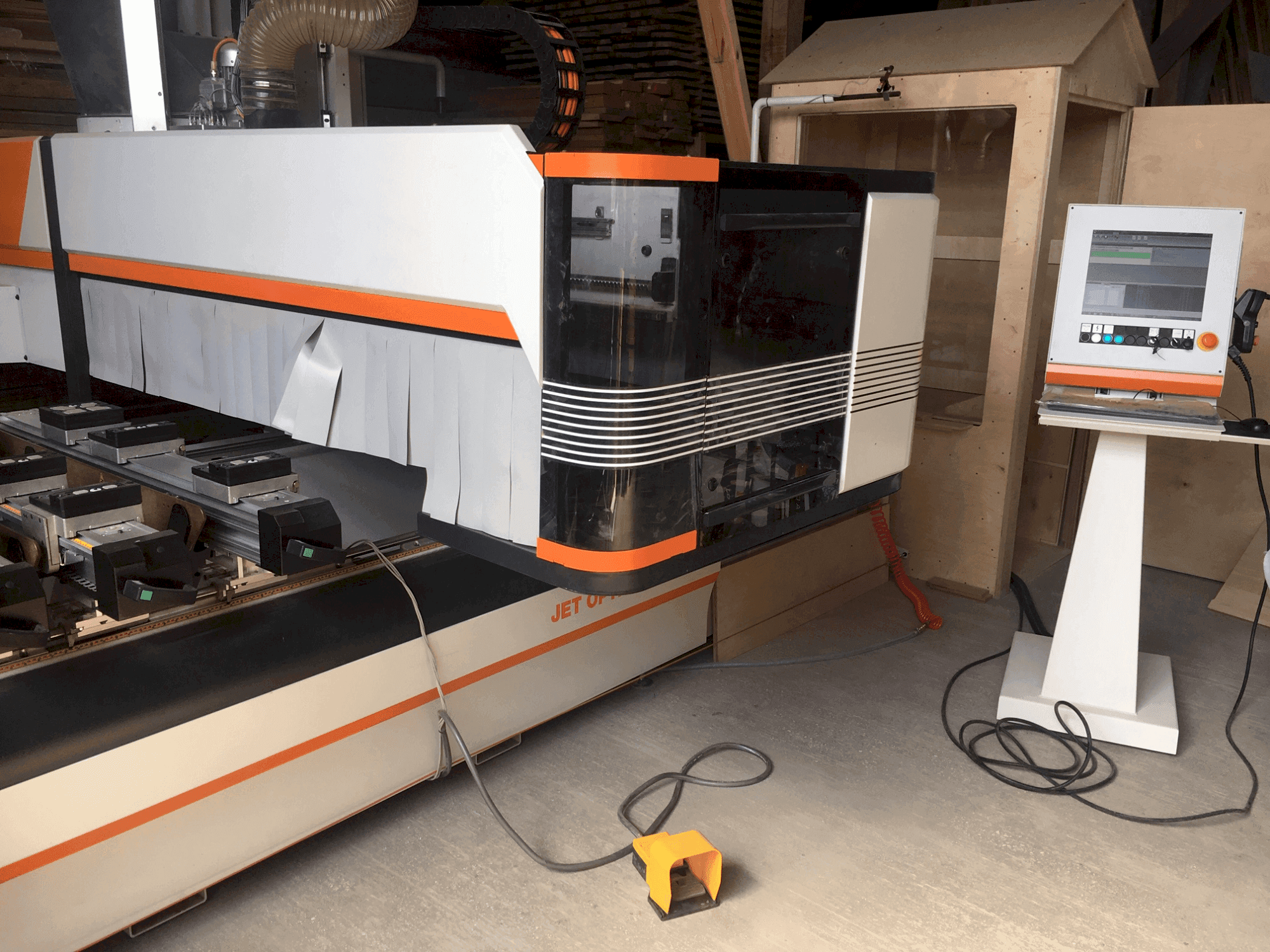

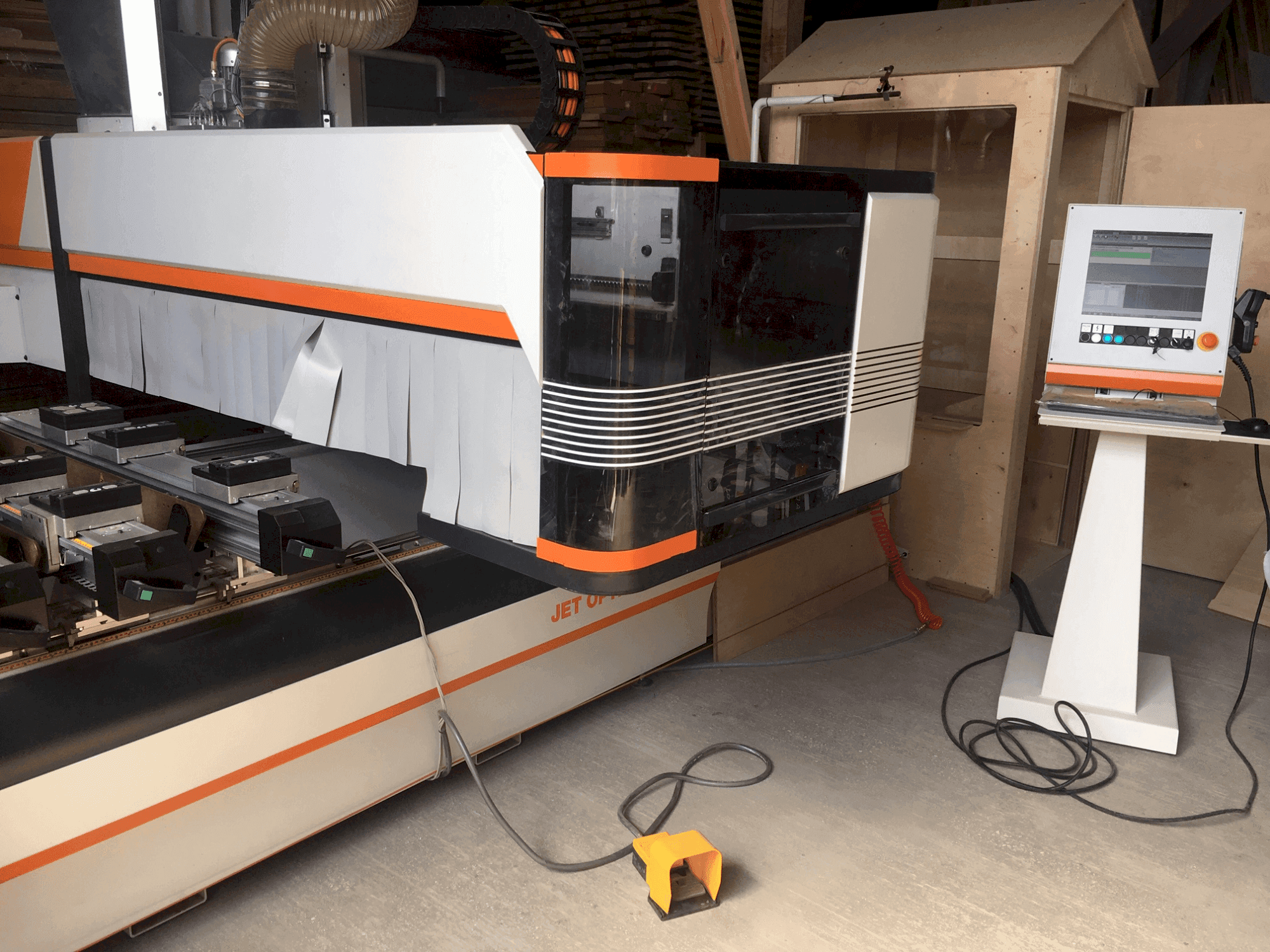

BUSELLATO - Jet Optima T5HU-WOO-BUS-2018-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Holzbearbeitung

- Busellato Jet Optima T5 Holzbearbeitungsmaschine

Diese Busellato Jet Optima T5 Holzbearbeitungsmaschine wurde im Jahr 2018 hergestellt. Sie ist mit einer TPA-Steuerung ausgestattet und hat 5 Achsen.

Übersicht

- Hersteller: BUSELLATO

- jahr: 2018

- MODELL: Jet Optima T5

- anwendungstyp: CNC-Bearbeitung

- Standort: Ungarn

- maschinentyp: CNC-Fräse

Technische Daten - BUSELLATO Jet Optima T5

Bewegung

- Anzahl der Achsen: 5

Zusätzliche Informationen

Maschinenvorteile

Qualitative Maschinenvorteile

- Automatische werkzeugradiuskorrektur, bohrkopf 18m (8x + 5y), 6 horizontalbohrer (4x - 2y), kreissäge: 120 mm.

- Werkzeugwegoptimierung zwischen den bearbeitungen, wassergekühlter 5-achs-kopf "jet 5" mit werkzeugspannung hsk 63, b: +185° bis -95°, c: +/- 360°, arbeitsbereich: 3050 x 1250 mm.

- Grafische darstellung der einstellungen der werkzeugbibliothek, anzeige der spindeldrehzahl und der aggregatpositionen.

- 2d-simulation und software zur berechnung von zykluszeiten, steuerungs- und diagnosesynopsen zur vereinfachung der maschinenbedienung.

- Bedrucken und grafisches bedrucken von programmierten werkstücken mit iso-codes, maschinensteuerungssoftware genesis evolution.

- Die programme können mit der "vorschau"-funktion leicht überprüft werden, elektrogeschweißter maschinenrahmen und bewegliche konsole mit verstärkten, verrippten stahllegierungsplatten, besonders verstärkt an den am stärksten belasteten stellen.

- Manuelle und maschinelle diagnosefunktionen mit echtzeit-reparaturvorschlägen und grafischer unterstützung.

- Grafische unterstützung bei der maschinenprogrammierung. Wiederholen von programmlisten und ausführen von benutzerdefinierten programmen.

- Import von iso-textdateien, "hold"-funktion mit sicherheitsmatte, bewegung der z-achse durch kugelumlaufspindeln erleichtert.

- Bearbeitung entlang von kurven und bögen für zeichenhöhe, abstand, zeilenabstand und buchstabenabstand, "sc" elektrodenspindel 11 kw - drehzahl 20. 000 u/min hsk, pc-konsole mit windows-betriebssystem, 17"-lcd-monitor.

Technische Maschinenvorteile

- Die arbeitshöhe der axialen z-achse der maschine beträgt 180 mm. Die tatsächlichen positionsgeschwindigkeiten der achsen sind wie folgt: x-achse: 70 m/min y-achse: 60 m/min z-achse: 30 m/min

- Zu den wichtigsten merkmalen gehören: integrierter kader mit reflexions-, rotations- und wiederholungsfunktionen usw.

- Das betriebssystem ermöglicht eine echtzeitsteuerung der maschine, eine automatische steuerung der arbeitsgeschwindigkeit mit streckenoptimierung und ein automatisches zentralschmiersystem.

- Anzeige von 2d- und 3d-darstellungen von werkstücken, rundes 12-fach werkzeugmagazin hsk 63.

- Parametrische programmierung, die die verwendung von mathematischen, trigonometrischen, inversen trigonometrischen und logischen formeln mit 300 variablen für die ausführung dieser formeln ermöglicht.

- Betrachtung und drehung der horizontalen und vertikalen ansichten, automatische reduzierung der vorschubgeschwindigkeit auf der grundlage des umrichterbetriebs.

- Einfache und vielseitige programmierung in mehreren ansichten, lineares 10-fach werkzeugmagazin hsk 63.

- Automatische geschwindigkeitskontrolle für den werkzeugeingriff, bewegung der y-achse durch kugelumlaufspindeln erleichtert.

- Abruf der werkzeugparameter aus dem programm, verschiebung der x-achse durch eine konvex gekrümmte zahnstange und ritzel.

- Programmierung auf höherer ebene (if-end-if) mit makros, import von dxf-dateien in das ascii-format.

Zusätzliche Informationen

Die Maschinenausstattung umfasst: Jet Cad Steuerungssoftware. 90 m3/h Vakuumpumpe. Zentraler Absaugpunkt. 6 "IMC"-Balken. 6 Vakuumsauger mit den Maßen 80x155 mm. 6 Vakuumsauger mit den Maßen 55x155 mm.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung