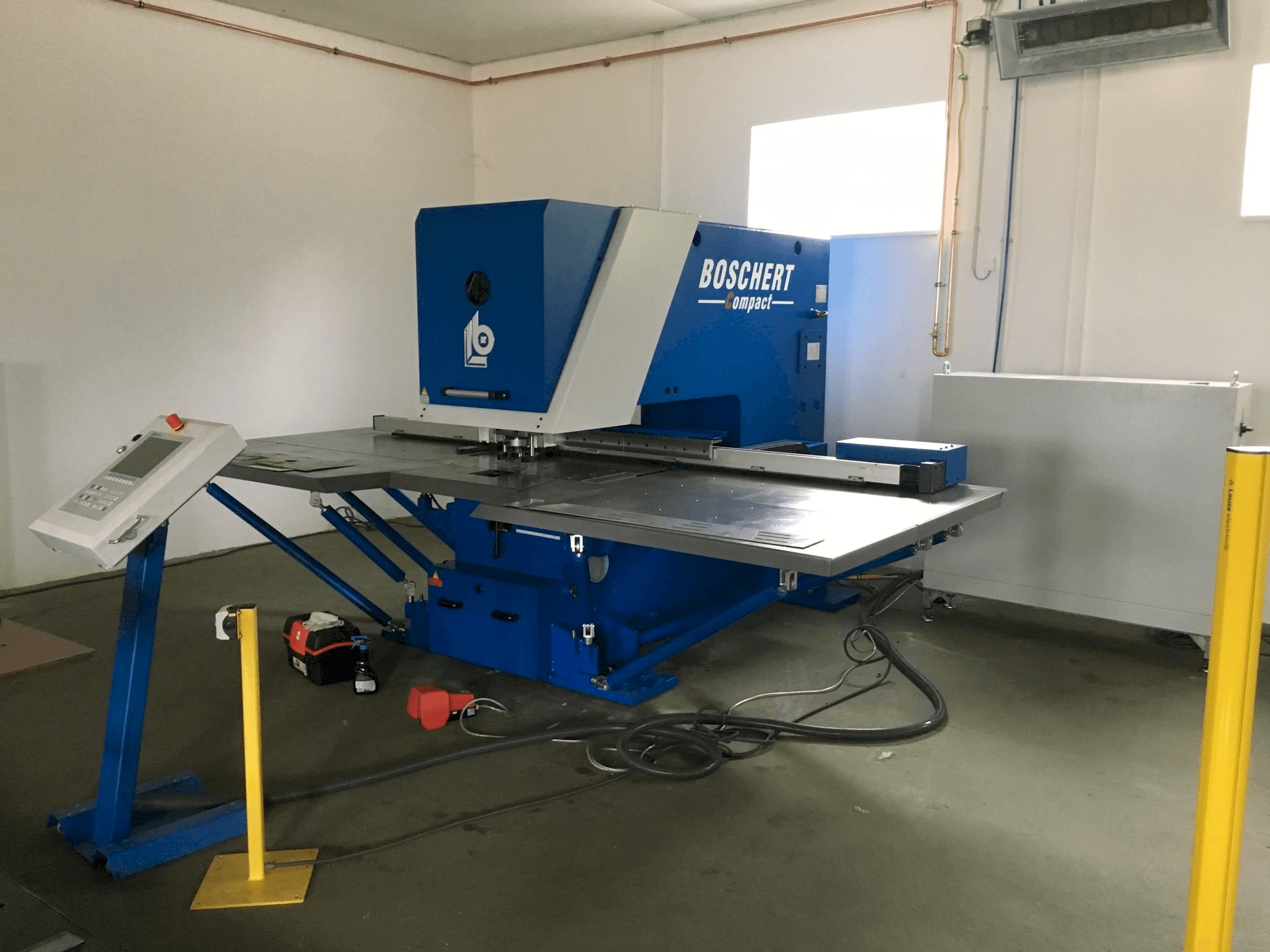

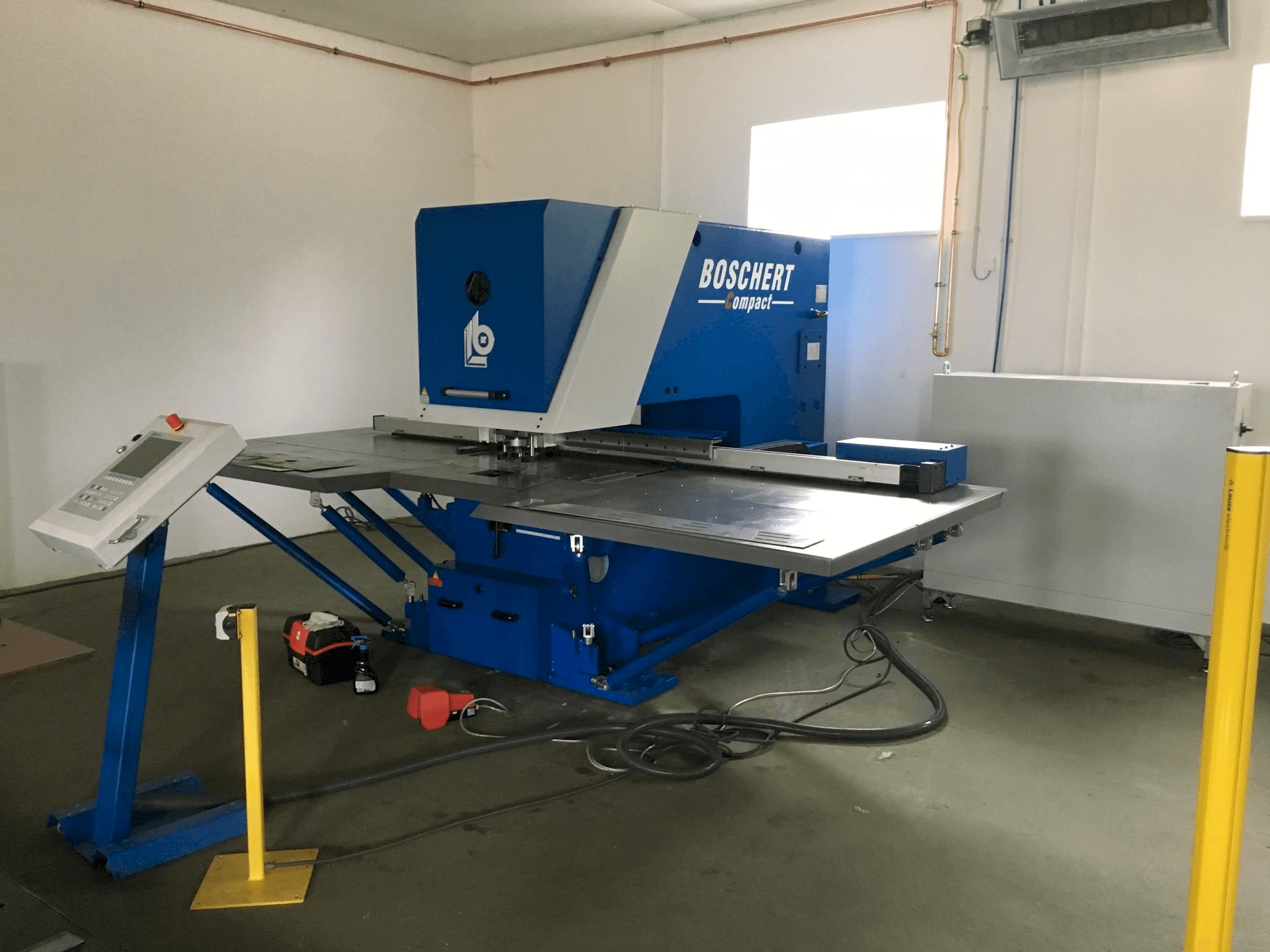

BOSCHERT - Compact 750 (2018)HU-PUN-BOS-2018-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Blechbearbeitungsmaschinen

- BOSCHERT Compact 750 Punching machine

This BOSCHERT Compact 750 Punching machine was manufactured in 2018. It has a table size of 750 mm (X-axis) and 2000 mm (Y-axis) and a punching depth of 750 mm with a maximum punching diameter of 105 mm. This punching machine is equipped with a punching force of up to 40 tons. Maximum cutting thickness for normal steel is at 6mm. It is build in a C-frame construction with appropriate oversizing. The cantilever structure allows for machining of parts larger than the machining space.

Übersicht

- Hersteller: BOSCHERT

- jahr: 2018

- MODELL: Compact 750 (2018)

- Produktionsstunden: 40

- anwendungstyp: Stanzen

- Standort: Ungarn

- maschinentyp: Revolverstanze

Technische Daten - BOSCHERT Compact 750 (2018)

Maße

- Maschinentiefe: 3165 mm

- Maschinenhöhe: 2100 mm

- Maschinengewicht: 14500 kg

Bewegung

- X-Achsverfahrweg: 750 mm

- Y-Achsverfahrweg: 2000 mm

Zusätzliche Informationen

Additional equipment

- Stripper holder with slots for pins

- Punch adjustment ring for punches up to diam. 30mm

- Punch adjustment ring for punches over diam. 30mm

- Punch holder for needles up to 6mm

- Punch holder for needles up to 10.5mm

- Punch adjustment unit for rectangle. oblong and square tools

Machine Benefits

Qualitative Machine Benefits

- Steel machine table with a gritted surface

- C-frame construction with appropriate oversizing. The cantilever structure allows for machining of parts larger than the machining space

- Hydraulic operation for adequate force even with large sheet thicknesses

- Programmable stroke length adjustment // photocell workspace protection

- Sheet lifter device with 2 pneumatic cylinders for movement

- Multi-tool memory expansion with usb and lan connections for labod control

- Automatic repositioning up to a maximum of x-9000mm

- Two guide rails on the left and right sides for precise suspension of the axes // adjustable positioning speed allows manual movement of the axes in any direction

- Screwing and drilling attachment // fast hydraulic / 800 strokes at marking

- Automatic clamp positioning // marking device

Technical Machine Benefits

- Punching force up to 40 tons

- Punching depth: 750 mm

- Maximum punching diameter: 105 mm

- Maximum stroke length: 90 mm

- Maximum cutting material thickness for normal steel: 6 mm

- Nibbling sequence: 3 mm

- Table height: 905 mm

- Positioning accuracy: 0. 1 mm // x-axis movement speed: 1,000 mm/s // y-axis movement speed: 1,000 mm/s // stroke rate at 20mm stroke: 155 strokes/minute

- Displacement x: 0-810 mm, y: 0-2080 mm

- Maximum positioning speed on the x-axis: 60 meters/minute // maximum positioning speed on the y-axis: 30 meters/minute // positioning accuracy for sheet movement: 0. 1 mm

Extra Information

Two-axis graphical CNC control system LABOD PC // Waste removal suction // Spray lubrication // Revotool without rotation for standard head // Revotool index only for rotation // Balls brushes in the table // Cnc / had software to import dxf files // CE compliance

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung