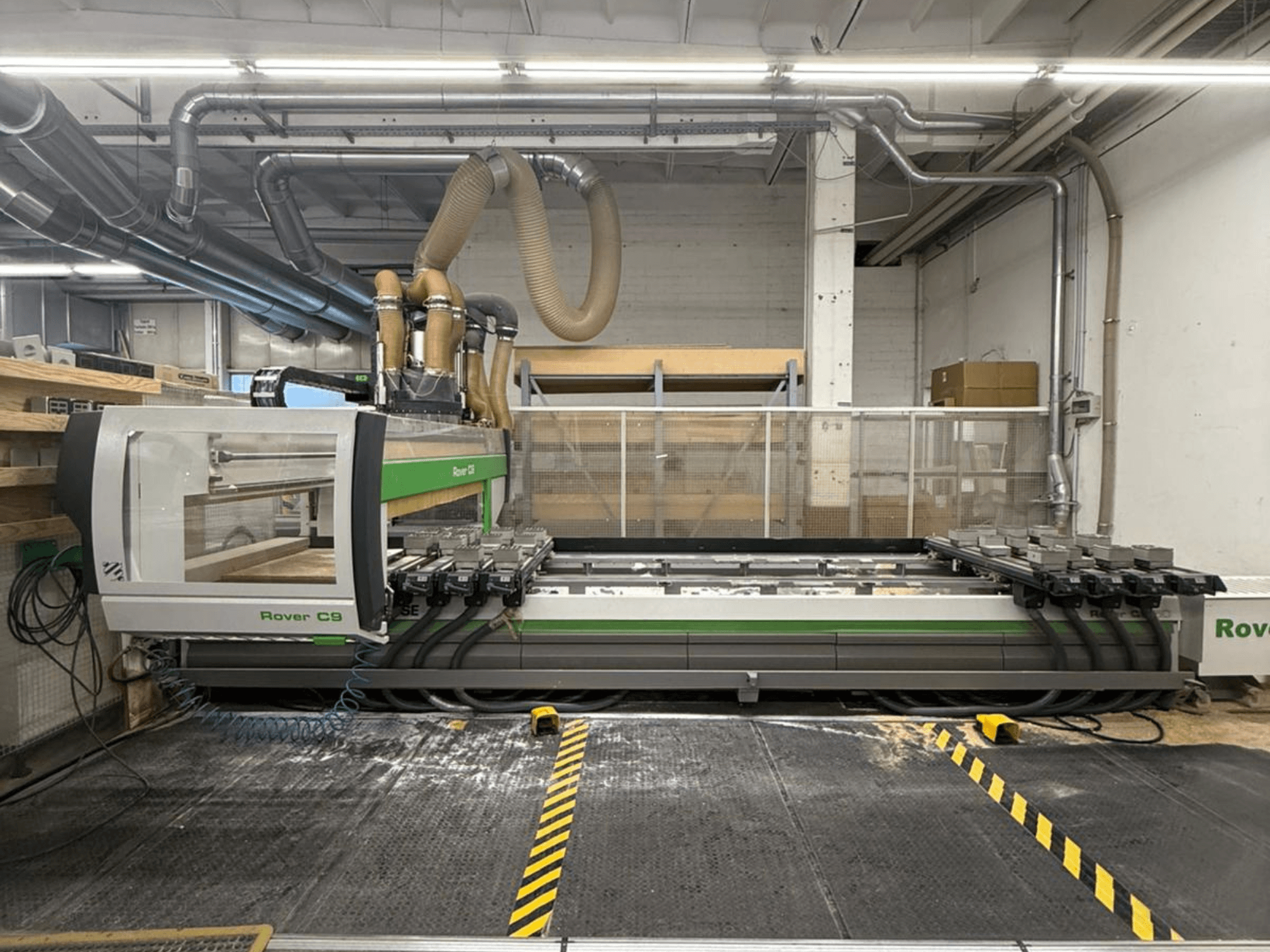

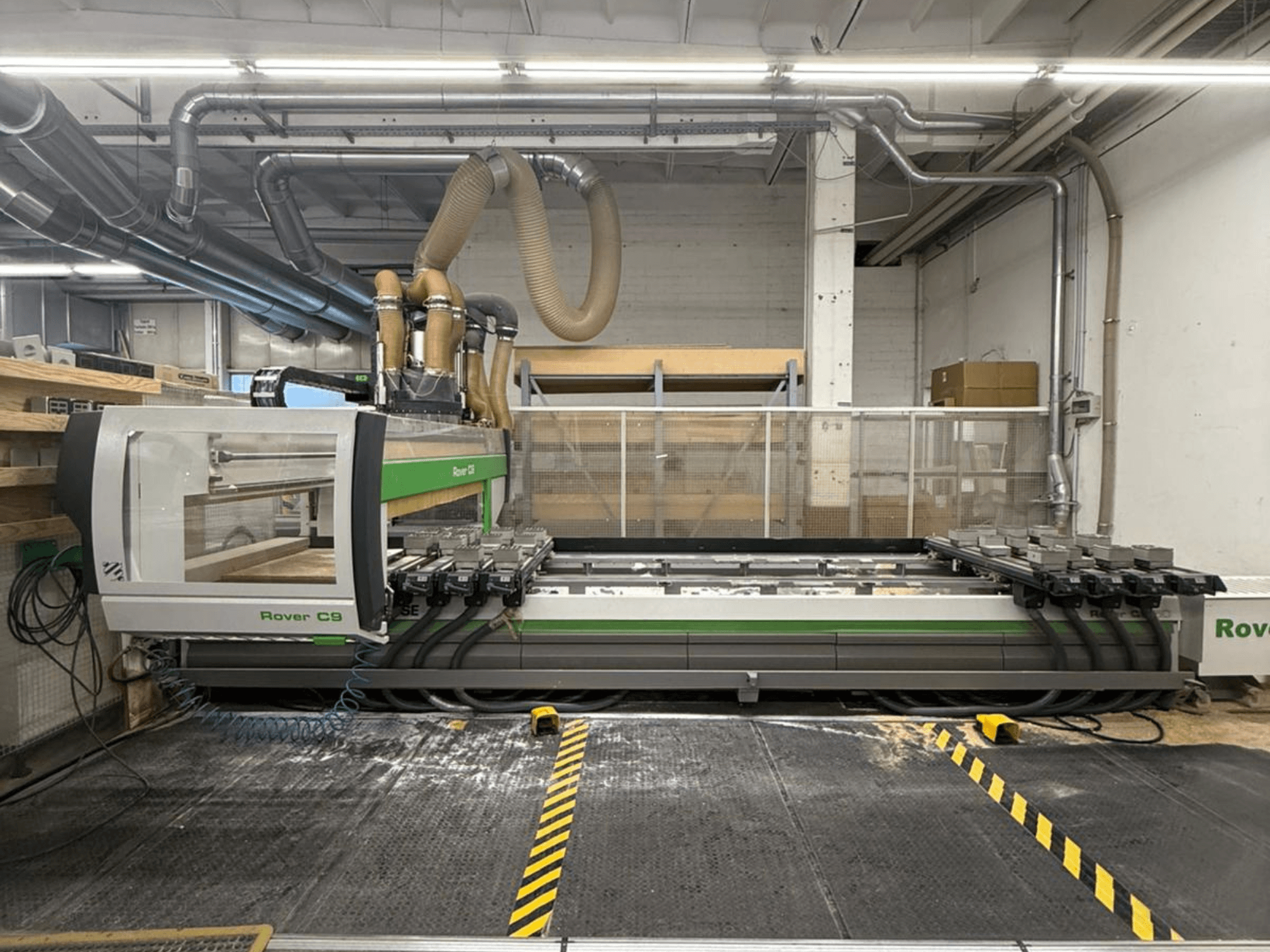

BIESSE - ROVER C9.50DE-CNC-BIE-2007-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Holzbearbeitung

- ➤ Gebrauchte BIESSE ROVER C9.50 zu verkaufen | gindumac.com

Diese 5-Achsen-Biesse Rover C9.50 wurde 2007 hergestellt. Sie verfügt über einen großen Arbeitsbereich (X=4600 mm, Y=1935 mm, Z=275 mm), ein automatisches Schmiersystem und eine Steuereinheit für 5-Achsen-Interpolation. Die Maschine verfügt über ein Vakuumsystem, ein Förderband für die Späneabfuhr und eine Flüssigkeitskühlung. Wenn Sie auf der Suche nach hochwertigen CNC-Bearbeitungsmöglichkeiten sind, sollten Sie die Biesse Rover C9.50 Maschine in Betracht ziehen, die wir zum Verkauf anbieten. Kontaktieren Sie uns für weitere Informationen.

Übersicht

- Hersteller: BIESSE

- jahr: 2007

- MODELL: ROVER C9.50

- anwendungstyp: CNC-Bearbeitung

- Standort: Deutschland

- maschinentyp: CNC-Bearbeitungszentrum

- Verfügbar ab: 01/06/2026

Technische Daten - BIESSE ROVER C9.50

Bewegung

- Anzahl der Achsen: 5

- X-Achsen-Verfahrweg: 4600 mm

- Y-Achsen-Verfahrweg: 1935 mm

- Z-Achsen-Verfahrweg: 275 mm

Zusätzliche Informationen

Arbeitstisch und Aufspannung

8 ATS-Plattenhalter (L = 1525 mm) und 24 Gleitschienen

Automatische Positionierung der Plattenhalter und Gleitschienen (EPS X-Y)

Pneumatisches Verriegelungssystem, unterteilt in 2 Arbeitsbereiche in X

8 hintere Referenzanschläge, Hub 115 mm

8 Anschläge, Hub 140 mm, positioniert bei 1175 mm (L = 1280 / 1525 / 1800 mm)

8 Anschläge, Hub 140 mm, positioniert bei 770 mm (L = 1280 / 1525 / 1800 mm)

4 Seitenanschläge, Hub 140 mm (2 links + 2 rechts), mit pneumatischem System

4 abnehmbare Mittelanschläge, Hub 140 mm (2 links + 2 rechts), mit pneumatischem System

Sensor zur Erkennung abgesenkter Anschläge

Pneumatisches System für Hubstangenhalter

6 Hubstangenhalter für einfaches Beladen (H = 74 mm Module)

Vakuum

Vakuumsystem für eine 250 m3/h Pumpe

250 m3/h Drehschieber-Vakuumpumpe für Standard-Vakuumsystem

Bearbeitungseinheiten und Konfiguration

Zusammensetzung C3-A1:

Vorrichtung zur Montage von Spanabweisern mit pneumatischen oder induktiven Sensoren an einer 5-Achsen-Bearbeitungseinheit

Flansch für die Montage von Einheiten auf einer Arbeitseinheit mit 5 interpolierenden Achsen (Einheiten nur verwendbar, wenn die elektrische Spindel vertikal ist)

Zusammensetzung C3-P2:

Zusätzlicher Z-Schlitten für hintere Arbeitseinheiten, gesteuert durch eine unabhängige Z-Achse

Bohrkopf BH 42 L

Kettenwerkzeugwechsler mit 22 Positionen (180 mm Achsabstand)

Eisengreifer für Spanabweiser mit pneumatischem oder induktivem Sensor, im Kettenwerkzeugwechsler positioniert

RH Späneabweiser mit induktivem Sensor für Standard-Elektrospindel oder 15 kW 5-Achsen-Elektrospindel (erfordert Vorrichtung für Späneabweiser; erfordert Flansch für Montageeinheiten bei Verwendung einer 5-Achsen-Elektrospindel; erfordert C-Achse bei Verwendung einer Standard-Elektrospindel)

Systeme

Automatisches Schmiersystem

Steuereinheit mit 5 interpolierenden Achsen

Zusätzliche Ausrüstung

Förderband zum Abtransport von Spänen und Schrottteilen (Späneförderer)

Flüssigkeitskühlgerät für flüssigkeitsgekühlte Systeme (kann zwei Elektrospindeln oder eine Elektrospindel plus einen flüssigkeitsgekühlten Bohrkopf kühlen)

Hinweis: Die technischen Daten und Beschreibungen sind der Original-Auftragsbestätigung entnommen und dienen nur zur Information; sie sind nicht verbindlich.

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung