Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

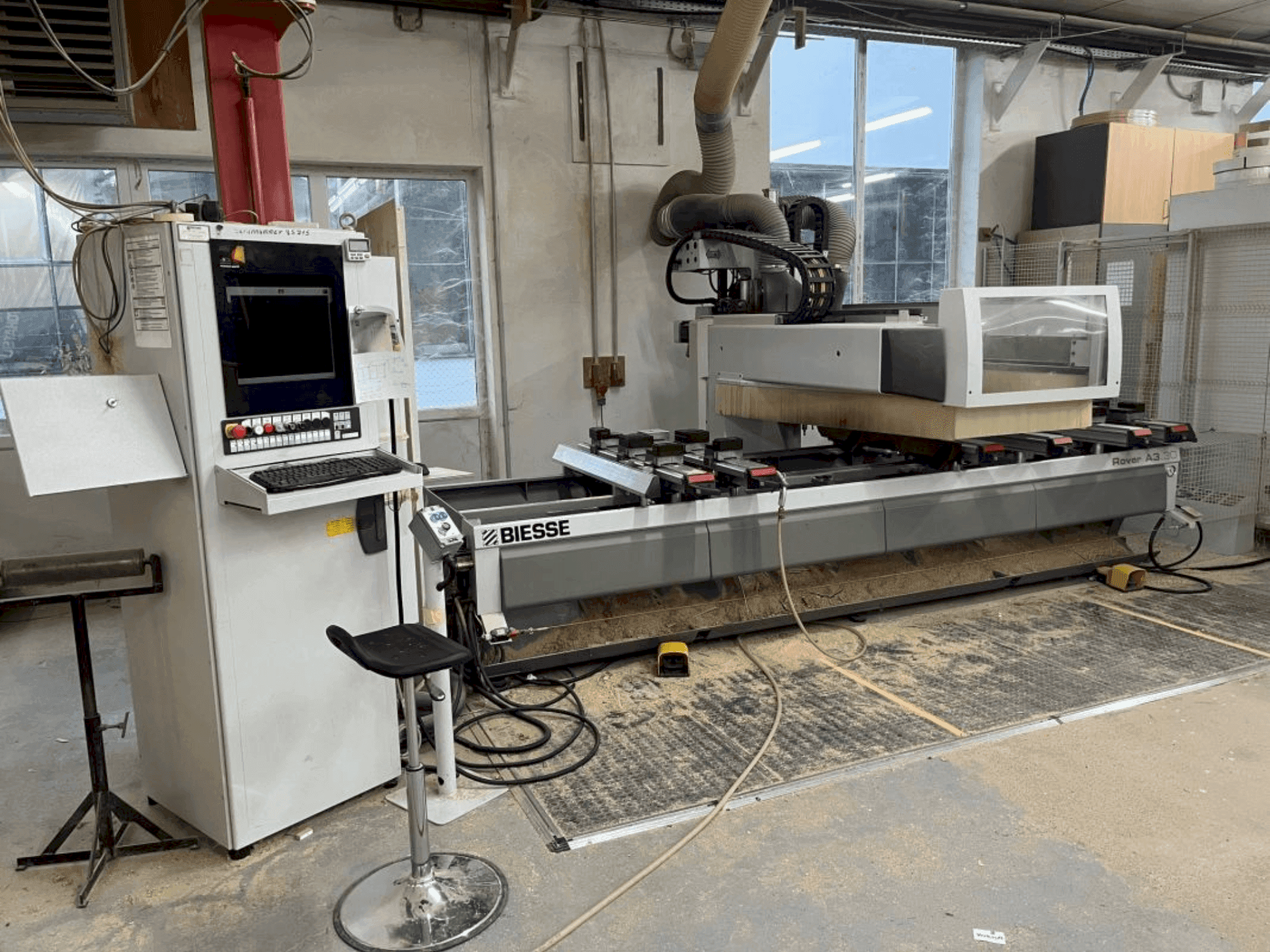

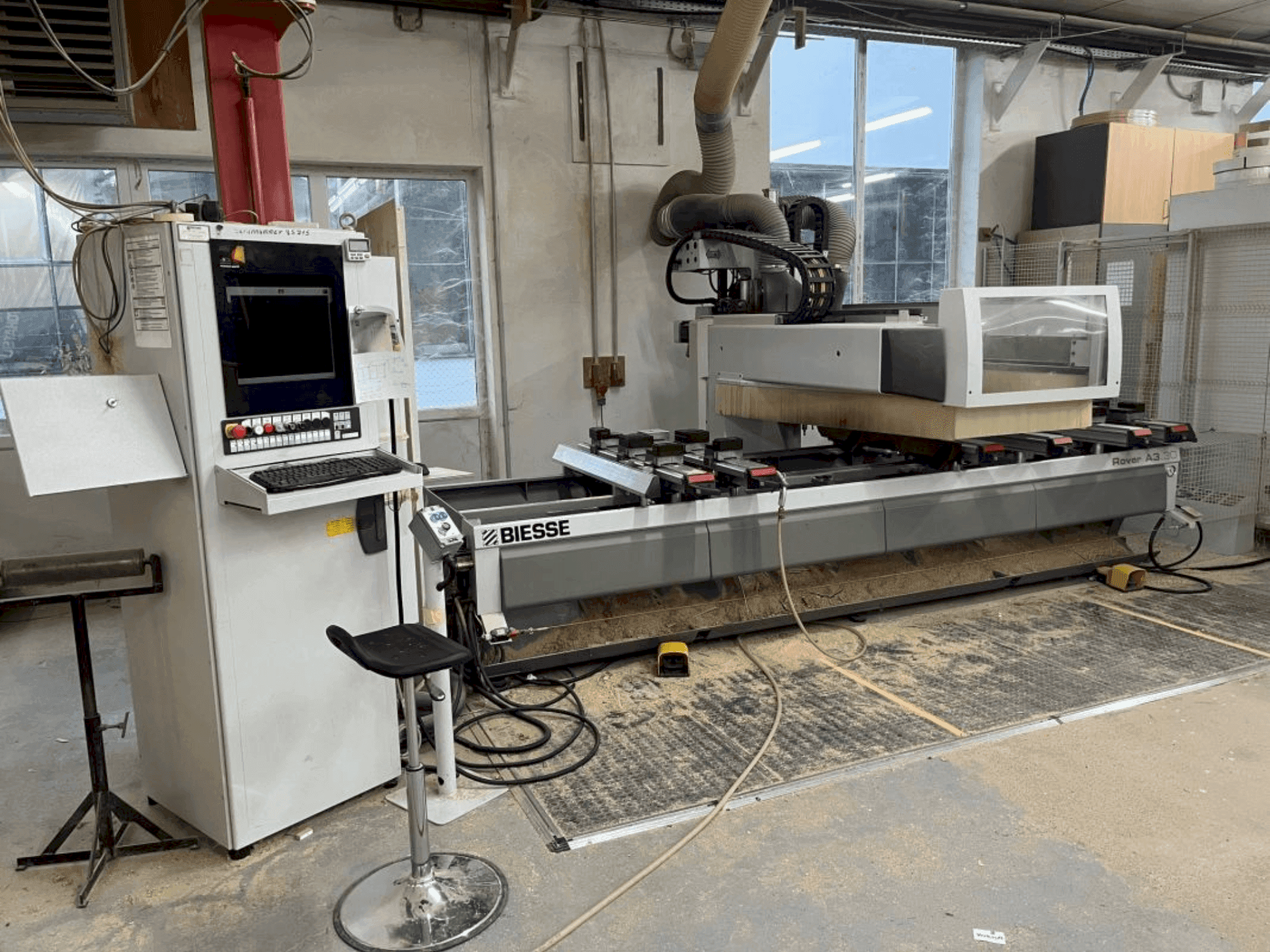

BIESSE - ROVER ADE-CNC-BIE-2007-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Holzbearbeitung

- ➤ Gebrauchte BIESSE ROVER A - 2007 - Zu verkaufen | gindumac.com

Diese BIESSE ROVER A wurde im Jahr 2007 hergestellt. Ein gebrauchtes CNC-Holzbearbeitungszentrum mit einer robusten 7 kW Elektrospindel, einem vielseitigen Bohrkopf BH 21L und einem Revolverwerkzeugmagazin mit 10 Plätzen. Es verfügt über ein Vakuumsystem mit einer 90 m3/h-Pumpe und einer Hilfsunterstützung, die die Betriebseffizienz erhöht. Ideal für detaillierte Holzbearbeitungsaufgaben. Kontaktieren Sie uns für weitere Informationen über diese Maschine.

Übersicht

- Hersteller: BIESSE

- jahr: 2007

- MODELL: ROVER A

- anwendungstyp: CNC-Bearbeitung

- Standort: Deutschland

- maschinentyp: CNC-Holzbearbeitungszentrum

Technische Daten - BIESSE ROVER A

Bewegung

- Y-Achsen-Verfahrweg: 1635 mm

- Z-Achsen-Verfahrweg: 200 mm

Zusätzliche Informationen

Zusätzliche Ausrüstung

- Schaltschrank: die Maschine kann mit 380/400/414 V - 50/60 Hz geliefert werden

Maschinenvorteile

Technische Maschinenvorteile

- Arbeitsbereich: x = 3060 mm, y = 1260 mm, z = 150 mm

- Die achsen werden auf einer linearführung mit kugelumlauflagern geführt

- Automatisches schmiersystem

Zusätzliche Informationen

Inklusive Konverter für Elektrospindeln mit einer Leistung von max. 14 kW Werkstück 6 ATS-Werkstückauflagen - L = 1200 mm 6 Anschläge mit 115 mm Hub, pneumatisch absenkbar, CNC-gesteuert, Ø 22 mm 6 Anschläge mit 115 mm Hub in 970 mm Abstand von hinten, pneumatisch absenkbar, CNC-gesteuert, Ø 22 mm 4 Seitenanschläge mit 115 mm Hub komplett mit pneumatischer Ausrüstung, pneumatisch absenkbar CNC-gesteuert, Ø 22 mm 4 abnehmbare Mittelanschläge mit 115 mm Hub inkl. Steuerung, pneumatisch absenkbar CNC-gesteuert, Ø 22 mm 12 Schmalteilspanner Pneumatische Vorrüstung für Positionierhilfe 4 Positionierhilfen (jede Positionierhilfe kann 36 kg tragen) 18 Vakuummodule 132 x 146 x H48 mm (jedes Modul ist leicht entnehmbar und auf dem Modulträger im 15°-Raster drehbar) Vorbereitung für Späneförderband im Maschinenbett integriert Vakuumanlage Vakuumpumpe 90 m3/h bei 50 Hz, 108 m3/h bei 60 Hz Zusätzliches Vakuumsystem Werkzeuge 7 kW (9,5 HP) Elektrospindel mit ISO 30 Adapter 6,6 kW (9 PS), 12000 U/min Wendeplatte S1 7 kW (9,5 PS), 12000 U/min Wendeplatte S6 Drehzahlen von 1000 - 24000 U/min NC-programmierbar Bohrkopf BH 21L, ausgestattet mit 21 unabhängigen Werkzeugen Nutsäge in X-Richtung, Durchmesser 120 mm (Schnitttiefe max. 25 mm) Revolverwerkzeugmagazin mit 10 Plätzen Max. Ø bei voller Bestückung (10 Werkzeuge): 120 mm Max. Gesamtgewicht: 40 kg

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung