Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

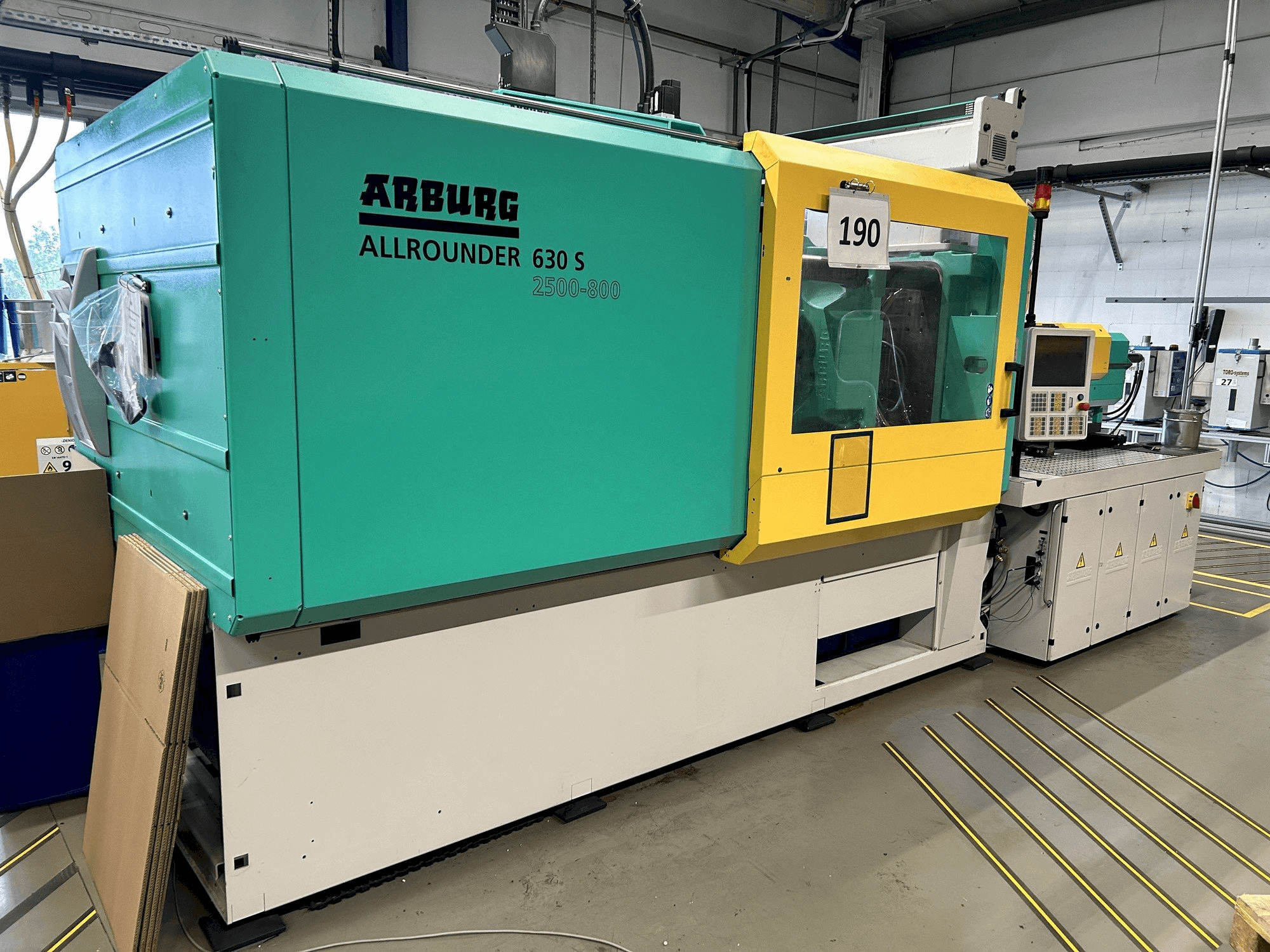

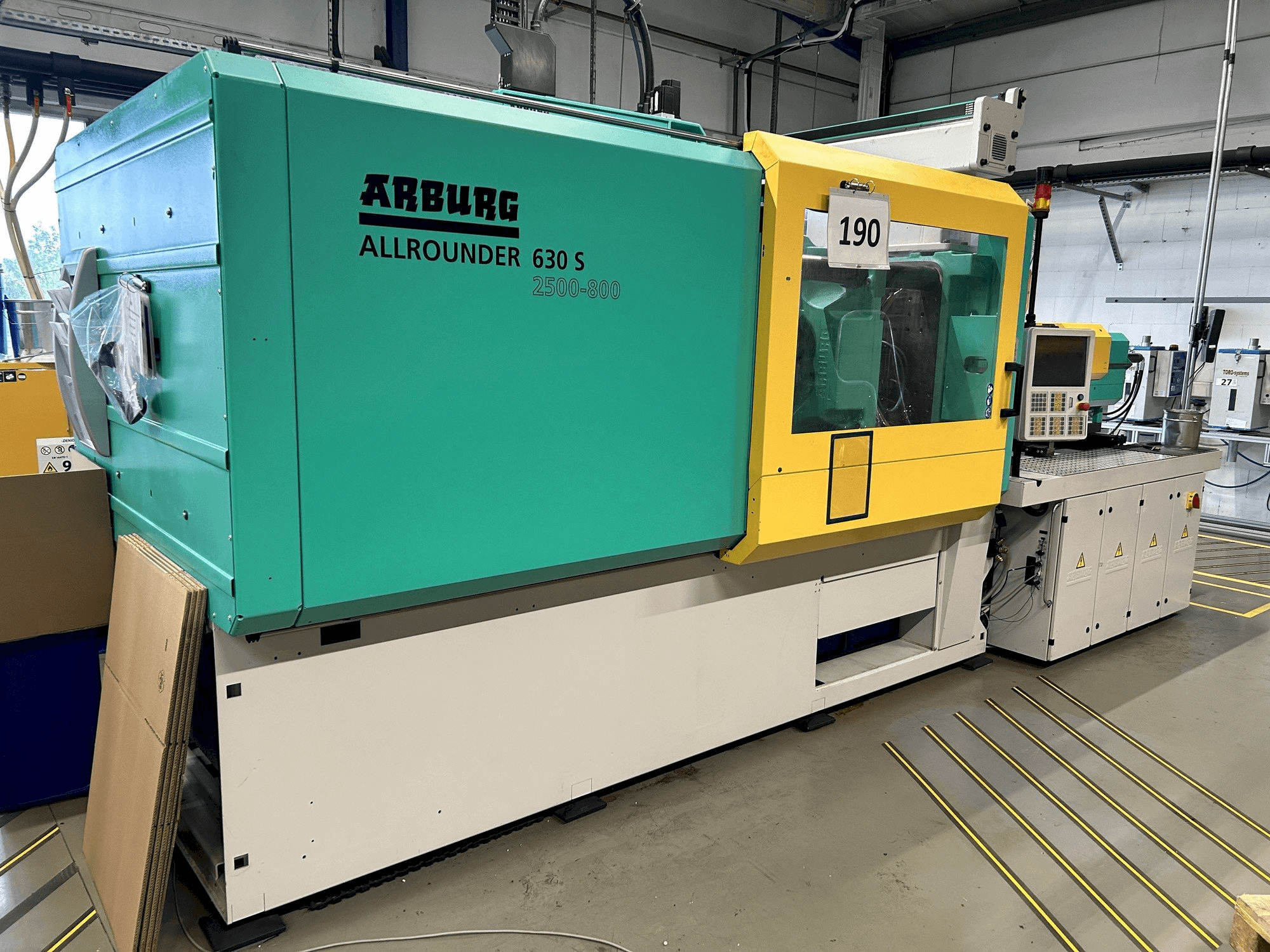

Arburg - Allrounder 630S 2500-800DE-INJ-ARB-2016-00002

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Kunststoffverarbeitungs-Maschinen

- Used Injection Moulding Machine Arburg Allrounder 630S 2500-800 - 2016 - for sale | gindumac.com

This ARBURG Allrounder 630S 2500-800 injection moulding machine was manufactured in May 2016. It offers a robust 2750kN clamping force, with a hydraulic drive system and precise control features, including 18 hot runner control zones. Key specifications include 45mm screw diameter, a 318cm³ dosing volume, 2470 bar maximum injection pressure, and a 242 cm³/s injection speed, ensuring high performance and consistent quality in production. Furthermore, it's equipped with a Multilift Select robotic system, enhancing automation and efficiency in handling. The ARBURG Allrounder machine we have for sale is tailored for high-volume and intricate moulding operations. It is in very good condition, and has low hours (only 4507 automatic hours) as it was mainly used as technical center machine for sampling and tryouts. Contact us for more information about this injection moulding machine. See original order confirmation (German) for further details attached below.

Übersicht

- Hersteller: Arburg

- jahr: 2016

- MODELL: Allrounder 630S 2500-800

- Produktionsstunden: 4507

- anwendungstyp: Spritzgießen

- Standort: Deutschland

- maschinentyp: Hydraulische Spritzgießmaschine

- Marke Steuergerät: ARBURG

Technische Daten - Arburg Allrounder 630S 2500-800

Steuerung

- Steuerungsmarke: ARBURG

- Steuerungsmodell: Selogica

Technische Spezifikation

- Klemmkraft: 2500 kN

- Max. Schussgewicht: 291 g

- Schneckendurchmesser: 45 mm

Zusätzliche Informationen

Additional equipment

- Robot system: Arburg Multilift Select with Payload: 15 kg, 3-CNC axes (X=2000/Y=700/Z=1000) + C-axis (O° / 90°, 24 Nm), and integration

- Extended mold installation height via adjustment plate

- Interface for communication with Kistler CoMo Injection

- Conveyor belt

- Safety fence for Multilift operation

Machine Benefits

Qualitative Machine Benefits

- Integrated robot system (arburg multilift select) for efficient handling and production automation

- It is in very good condition, and has low hours (only 4507 automatic hours)

- Mainly used as technical center machine for sampling and tryouts

Technical Machine Benefits

- Number of core pulls (hydraulically controlled): 6

- Number of hot runner control zones: 18

Extra Information

Machine cycles: 338114 // Operating hours pump: 7868 // Operating hours automatic: 4507 // Operating hours semi-automatic: 570 // Operating hours robot system: 2315

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Unterlagen

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung