Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

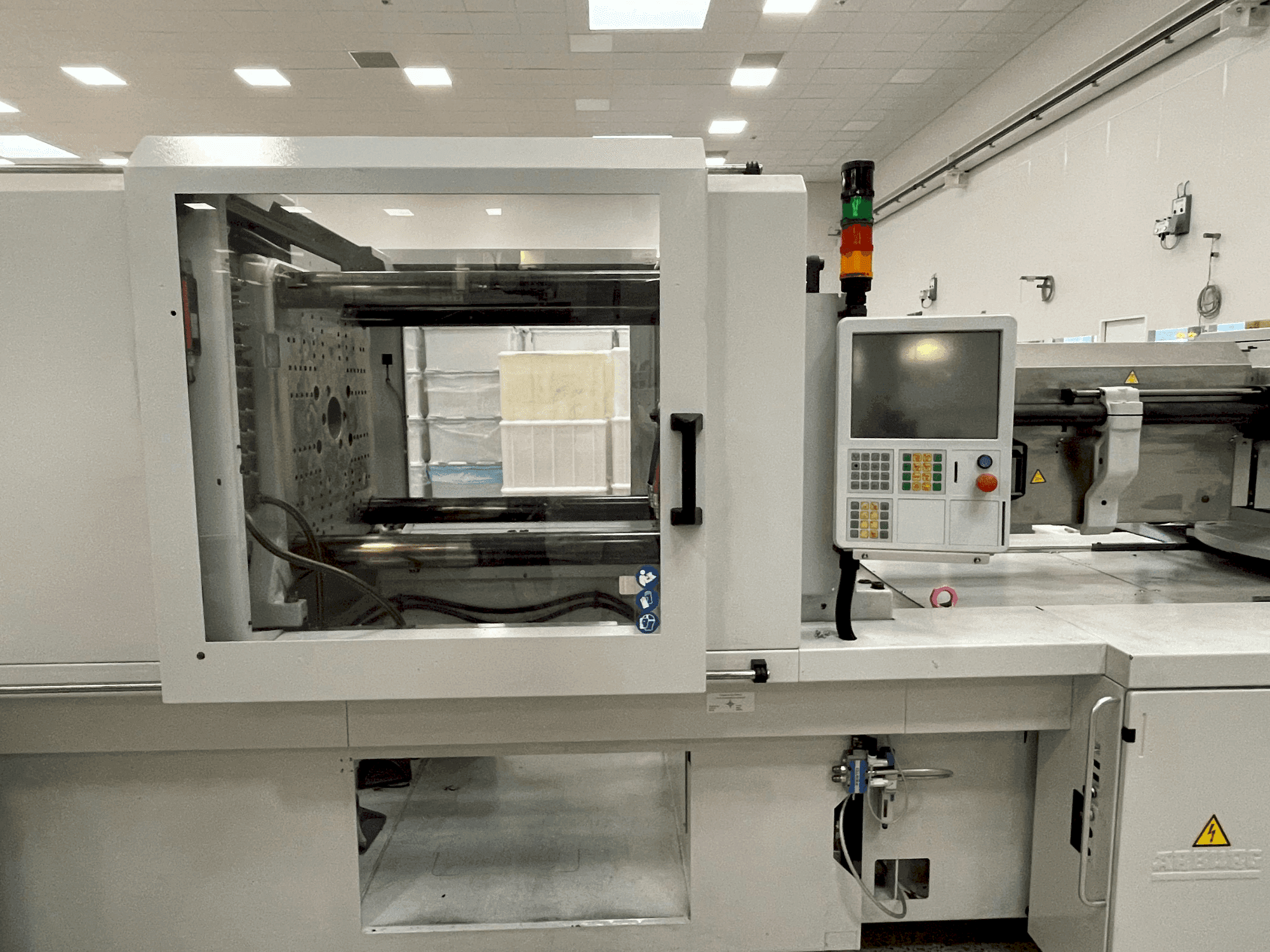

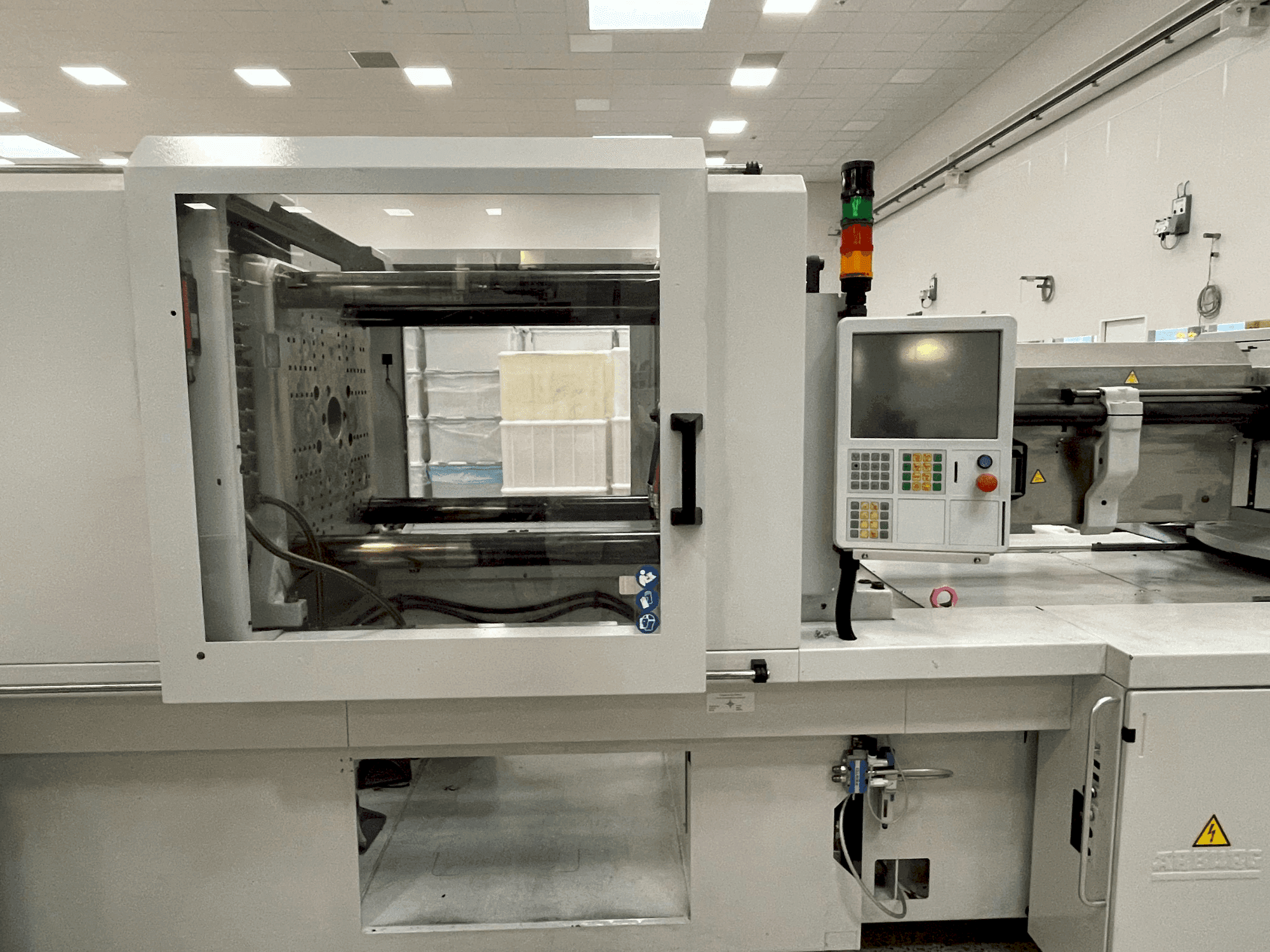

Arburg - Allrounder 570 H 2000-1300DE-INJ-ARB-2014-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Kunststoffverarbeitungs-Maschinen

- ARBURG Allrounder 570 H 2000-1300 Spritzgießmaschine

Diese ARBURG Allrounder 570 H 2000-1300 HIDRIVE Spritzgießmaschine wurde im Jahr 2014 in Deutschland hergestellt. Sie hat eine Schließkraft von 2000 kN und ist mit einem Thermoplastzylinder von 60 mm mit langer Barriereschnecke ausgestattet (offene Düse 60 mm, Düsenspitzenradius 15, Heizband für offene Düse). Zusätzlich verfügt sie über eine servoelektrische Formhöhenverstellung mit automatischer Schließkraftregelung, einen zentralen Aufspannplattensatz Ø 125 mm, ein auf 650 mm erhöhtes maximales Einbaumaß und einen um 10% erhöhten Einspritzdruck (max. 2500 bar je nach Schnecke). Siehe Übersicht der Gesamtkonfiguration als PDF (DE) unten angehängt. Wichtiger Hinweis: Die Spritzeinheit ist undicht, es liegt ein Kostenvoranschlag von Arburg über ca. 15.000 Euro netto inklusive Montage vor. Dieser Mangel ist noch nicht behoben, da die Maschine derzeit nicht im Einsatz ist. Nicht im Verkauf enthalten sind das Gehäuse, die auf den Bildern sichtbaren Trichter und sonstiges Zubehör. Die Maschine ist bereits vom Netz genommen worden und kann nicht in Betrieb besichtigt werden. Die Pumpenbetriebsstunden liegen bei 63.202 und Betriebsstunden bei 50.361 h.

Übersicht

- Hersteller: Arburg

- jahr: 2014

- MODELL: Allrounder 570 H 2000-1300

- Produktionsstunden: 63202

- anwendungstyp: Spritzgießen

- Standort: Deutschland

- maschinentyp: Hydraulische Spritzgießmaschine

- Marke Steuergerät: ARBURG

Technische Daten - Arburg Allrounder 570 H 2000-1300

Steuerung

- Steuerungshersteller: ARBURG

- Steuerungsmodell: SELOGICA direct

Technische Spezifikation

- Klemmkraft: 2000 kN

- Schraubendurchmesser: 60 mm

Zusätzliche Informationen

Zusätzliche Ausrüstung

- Ausstattungspaket Erweiterte Überwachung

- Ausstattungspaket Erweiterte Reisebewegungen

- Ausrüstungspaket Produktionskontrolle

- Ausstattungspaket Optimierung/Betriebsmittel

- Ausstattungspaket Qualitätssicherung

- Dokumentation Ausrüstungspaket

Maschinenvorteile

Qualitative Maschinenvorteile

- Einspritzeinheit angepasst für lange plastifiziereinheiten

- Servoelektrische formhöhenverstellung mit automatischer schließkraftregelung

- Einspritzdruck um 10% erhöht; schraubenabhängig max. 2500 bar

- Düsenkontaktkraft geregelt

- 12 elektrische heizungsregelkreise für die formbeheizung

- Frei programmierbare rampen für hydraulischen auswerfer

- Wassergekühlter schaltschrank

- Maschinenschutz ausgelegt für den betrieb mit und ohne multilift

- Schwachstrom-schaltschrank 800 x 800

Technische Maschinenvorteile

- Verstärkte schraubenkupplung - kupplungsgeometrie mehrzahnig

- Thermoplastischer zylinder 60 mm lang mit sperrschnecke

- Antriebseinheit mit 30 kw motor und 61. 11/min ladevolumenstrom

- Technologieebene speicherlaufwerk // thermoplastische verarbeitung

- Offene düse 60 mm // düsenspitzenradius 15 // heizband für offene düse

- Zentraler aufspannplattensatz Ø 125 mm

- Maximales einbaumaß auf 650 mm erhöht

- Auswerferdruck p /q gesteuert

- Kontinuierliche Ölkühlung und filterung

- Schnittstelle zum robotersystem (zu euromap 67)

Zusätzliche Informationen

50-polige Erweiterung Roboterschnittstelle (Euromap 12 und 67) F9264, 4 programmierbare Ein-/Ausgänge auf Klemmleiste, Steckdose vert. 1 CEE, 1 Schuko zusätzlich, Schneidwerk Temperaturkontrollgerät WKZ 20 mA, Druckerschnittstelle seriell USB, Compact Flash Schnittstelle für Datensatzspeicherung, Betriebserlaubnis mit Chipkarte nach EUROMAP 65, Halterung für PC-Tastatur mit USB-Anschluss, Akustische Störungsanzeige, AED - elektrom. Dosierantrieb, Schnittstelle Schutz der Schutzgittertür (EUROMAP 73), Parallelschaltung für Heizband Düsenspitze oder Adapter, Anfahrparameter, Schnittstelle Färbegerät, Absperrventil für Kühlwasser im Zulauf 1, Erhöhte Schwingelemente (100 mm Maschinenerhöhung), Maschinenbezogene Kühlkreisläufe gesteuert, aXw Control ScrewPilot , CD Betriebsanleitung und Ersatzteilliste , Ohne Granulatbehälter 50 L, Ohne Kühlwasserverteilung für Werkzeug, Auswerferplattenanschluss Sicherheitseinrichtung, Steckdose vert. 1 CEE,1 Schuko, Steuerungsverlängerung für Sondersignale, Maschine in Sonderlackierung

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung