Vielen Dank für Ihren Besuch

Diese Maschine wurde kürzlich verkauft. Schauen Sie sich gerne unsere vergleichbaren Maschinen an oder kontaktieren Sie uns direkt.

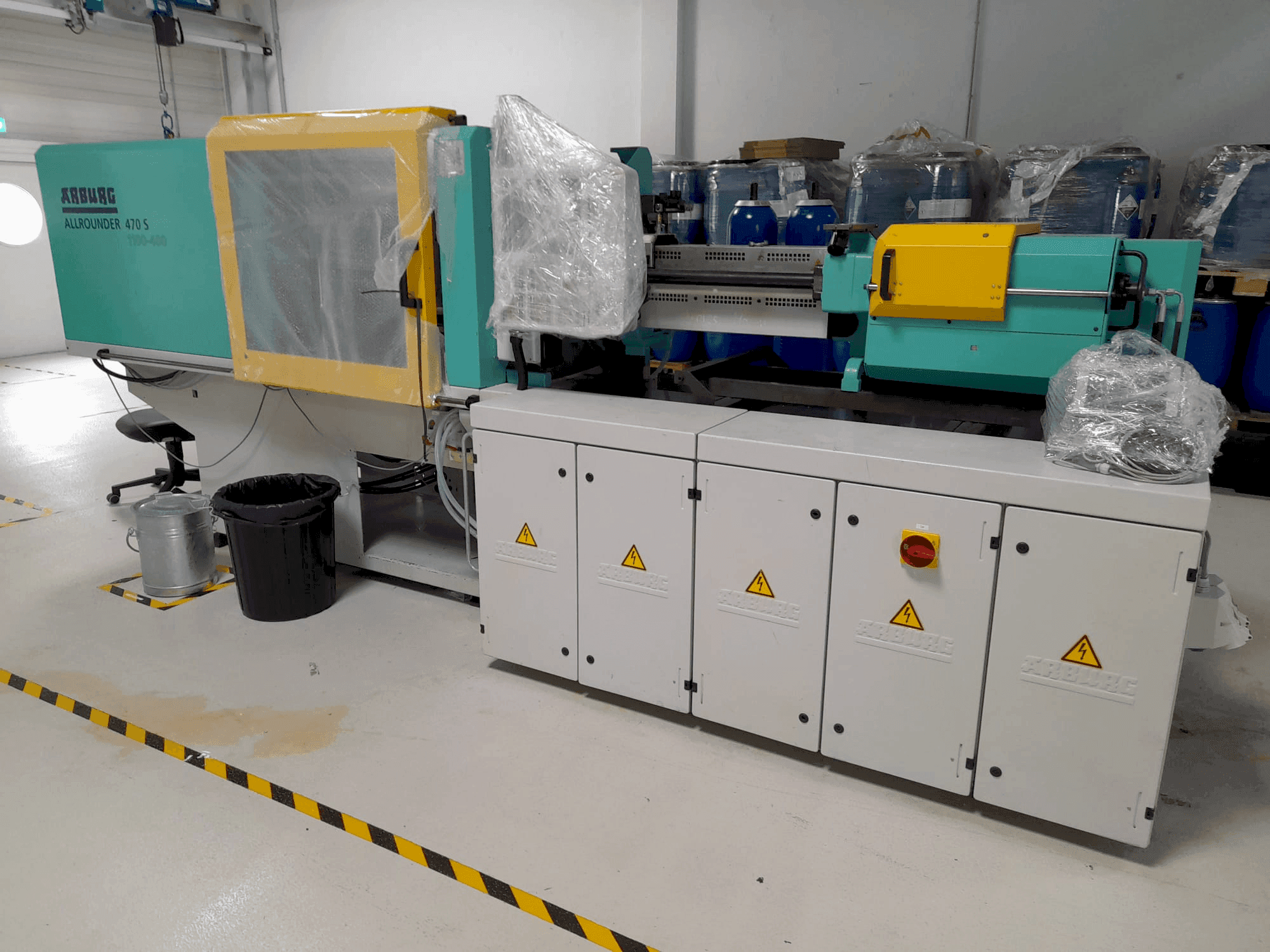

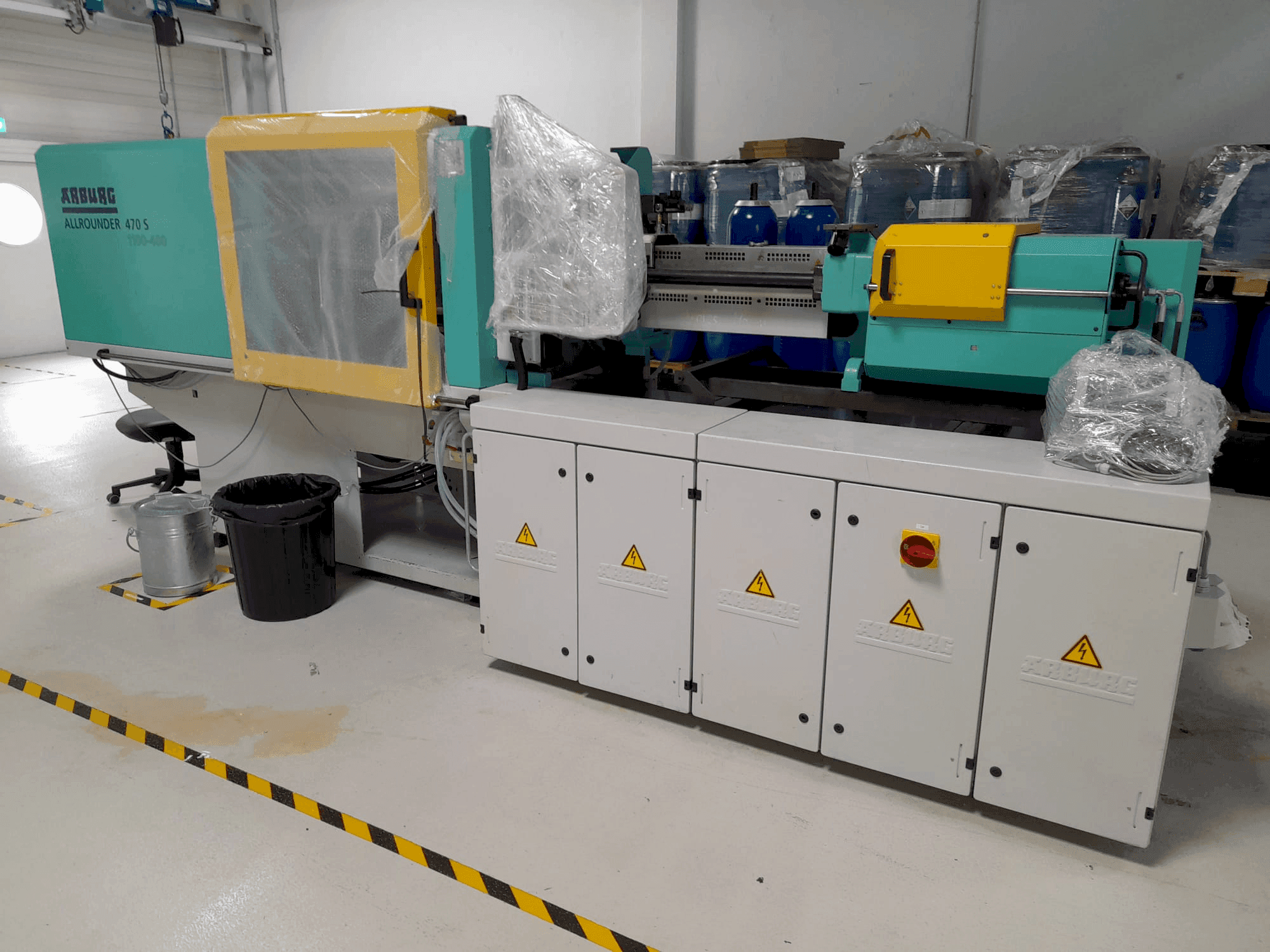

Arburg - Allrounder 470S 1100-400 with Multilift handlingDE-INJ-ARB-2010-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Kunststoffverarbeitungs-Maschinen

- ARBURG Allrounder 470S 1100-400 mit Multilift-Handling Spritzgießmaschine

Diese ARBURG Allrounder 470S 1100-400 mit Multilift Handling Spritzgießmaschine wurde im Jahr 2010 hergestellt und hat 63300 Pumpenbetriebsstunden. Sie ist mit zwei Ausblasvorrichtungen mit Druckminderer ausgestattet. Die Maschine hat einen MULTILIFT V SELECT Typ (quer auf der Maschine montiert, 3 CNC-Achsen, frei programmierbar, Achsen können gleichzeitig verfahren werden, Antrieb über Servomotoren). Verfügt über ein Schutzgehäuse Bosch-Profil mit Wellengitter, Zugangstür elektrisch geschützt

Übersicht

- Hersteller: Arburg

- jahr: 2010

- MODELL: Allrounder 470S 1100-400 with Multilift handling

- Produktionsstunden: 63300

- anwendungstyp: Spritzgießen

- Standort: Deutschland

- maschinentyp: Hydraulische Spritzgießmaschine

Technische Daten - Arburg Allrounder 470S 1100-400 with Multilift handling

Maße

- Maschinenbreite: 4500 mm

- Maschinenhöhe: 3000 mm

- Maschinengewicht: 4800 kg

Zusätzliche Informationen

Maschinenvorteile

Qualitative Maschinenvorteile

- Multilift v select (quer auf der maschine montiert, 3 cnc-achsen, frei programmierbar, achsen können gleichzeitig verfahren werden, antrieb über servomotoren)

- Technologiestufe 2 mit zwei steuerpumpen für kontrollierte maschinenbewegungen

- Schutzgehäuse bosch-profil mit wellengitter, zugangstür elektrisch geschützt

- 16 frei programmierbare eingänge

- 16 frei programmierbare ausgänge

- Temperaturregelung im schaltschrank durch wasserkühlung

- Sonderverfahren erweiterte zuhaltung

- 9 elektrische heizungsregelkreise für die formbeheizung (heißkanal) sensor typ j

Technische Maschinenvorteile

- Verriegelung: 1100 kn // spannung: 400 v / 50 hz // motor / heizung vorsicherung: 125 a // max. Einspritzvolumen: 154 ccm

- Positionsgeregelte schraube // druckspeicher für hohe drücke / geschwindigkeit

- Plastifizierzylinder 35 mm hoch verschleißfest und korrosionsbeständig, max. Verarbeitungstemperatur 450° b9ksppti8d // piezo-ladungsverstärker für innendruckmessung

- Programmierbare düsenanlagekraft // zentrierdurchmesser düsenseite: 125 mm

- Auswerfer mit schnellkupplung // auswerferhub max. : 175 mm formhöhe min. : 300 mm // maximaler plattenabstand: 950 mm // säulenabstände: 470 x 470 mm

- Druckerschnittstelle // temperiergeräteschnittstelle 20ma max. 6 geräte // allrounder an webschnittstelle // schnittstelle für einfärbe-/dosiergerät // schnittstelle für werkzeugüberwachung durch auswerferplattensicherung

- Maschinenzyklen: 4. 649. 834 h // pumpenbetriebsstunden: 63. 300 // betriebsstunden auto: 57,584

- Achslängen, achsgeschwindigkeit: z-achse (quer zur maschinenlängsachse) 1400 mm ---- mm/s // x-achse (parallel zur maschinenlängsachse) 400 mm --- mm/s // z-achse (eintauchachse) 600 mm ---- mm/s // c-achse pneumatische klappachse

- Ablagehöhe: 1100 +/- 200 mm

- 4 x pneumatikventile 5/3 mit arretierter mittelstellung für greiferfunktionen - 4 x vakuumeinrichtung inkl. Vakuumschalter für teileüberwachung

Zusätzliche Informationen

Zwei Ausblasvorrichtungen mit Druckminderer // Drei frei programmierbare Kernzüge // Nebenstromfilterung

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung